A flash memory based on halogen perovskite material and a preparation method thereof

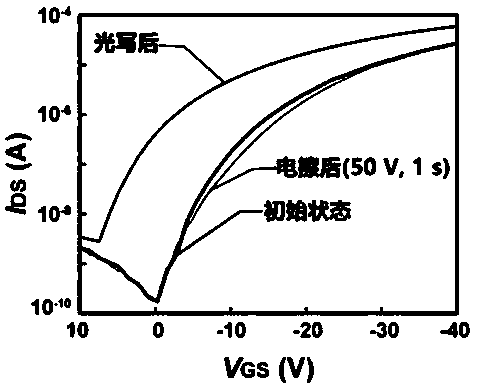

A perovskite material, a technology of flash memory, applied in the field of memory, can solve the problems of poor stability, slow read and write speed of flash memory, poor light regulation, etc., to achieve improved stability, excellent light response and light regulation characteristics, high The effect of charge carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

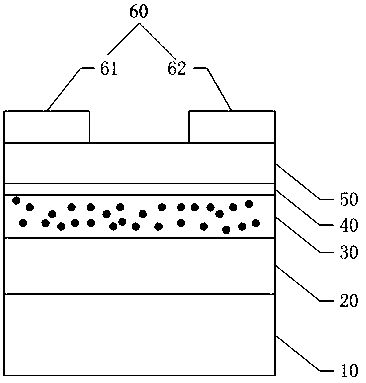

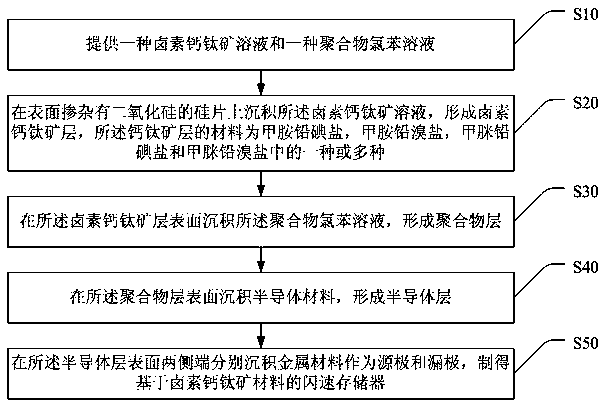

[0041] Based on the above-mentioned flash memory, the present invention also provides a preparation method of a flash memory based on a halogen perovskite material, wherein, as figure 2 shown, including steps:

[0042] S10, providing a kind of halogen perovskite solution and a kind of polymer chlorobenzene solution;

[0043] S20. Deposit the halogen perovskite solution on a silicon wafer doped with silicon dioxide on the surface to form a halogen perovskite layer. The material of the perovskite layer is methylamine lead iodide salt, methylamine lead bromide salt, formazan One or more of amidine lead iodide salt and formamidine lead bromide salt;

[0044] S30, depositing the polymer chlorobenzene solution on the surface of the halogen perovskite layer to form a polymer layer;

[0045] S40, depositing a semiconductor material on the surface of the polymer layer to form a semiconductor layer;

[0046] S50. Depositing metal materials on both sides of the surface of the semicon...

Embodiment 1

[0060] CH 3 NH 3 I(MAI) and PbI 2 MAPbI can be obtained by dissolving in dimethylformamide (DMF) at a ratio of 1:1. 3 Solution: Polymethyl methacrylate (PMMA) powder is dissolved in the chlorobenzene solution according to a certain ratio, and the mixed solution is placed in an ultrasonic machine so that PMMA is evenly dispersed in the solution to obtain a PMMA chlorobenzene solution.

[0061] The prepared MAPbI 3 The solution was spin-coated on the cleaned silicon wafer with 100nm silicon dioxide on the surface at 3000rpm for 40s, and annealed at 120°C for 40min after spin-coating to completely remove the residual solvent to obtain a halogen perovskite layer.

[0062] A uniform PMMA chlorobenzene solution was spin-coated on the surface of the halogen perovskite layer at 3000 rpm for 40 s, and annealed at 120° C. for 30 min after spin-coating to obtain a polymer layer.

[0063] Pentacene of about 30nm in 10 at a rate of 0.1 Å / s -6 In the form of thermal evaporation under T...

Embodiment 2

[0066] CH 3 NH 3 Br(MABr) and PbBr 2 MAPbBr can be obtained by dissolving in dimethylformamide (DMF) at a ratio of 1:1. 3 Solution: dissolving polystyrene (PS) powder in a certain proportion in a chlorobenzene solution, placing the mixed solution in an ultrasonic machine so that PS is evenly dispersed in the solution to obtain a PS chlorobenzene solution.

[0067] The prepared MAPbBr 3 The solution was spin-coated on the cleaned silicon wafer with 100nm silicon dioxide on the surface at 3200rpm for 45s, and annealed at 140°C for 45min after spin-coating to completely remove the residual solvent to obtain a halogen perovskite layer.

[0068] A uniform PS chlorobenzene solution was spin-coated on the surface of the halogen perovskite layer at a speed of 3500 rpm for 45 seconds, and annealed at a temperature of 150° C. for 35 minutes after the spin-coating to obtain a polymer layer.

[0069] Pentacene of about 30nm in 10 at a rate of 0.1 Å / s -6 In the form of thermal evapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com