A kind of non-caking type cat litter and preparation method thereof

A non-caking, cat litter technology, applied in animal houses, applications, animal husbandry, etc., can solve the problems of cat litter with large dust, short water saturation time, poor deodorization ability, etc., and achieve fast water absorption, Good deodorizing ability and long saturation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

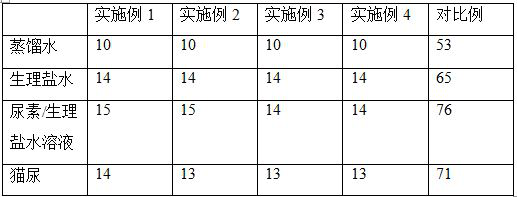

Examples

Embodiment 1

[0028] 1. A kind of non-caking type cat litter, is made up of the raw material of following weight part:

[0029] 80 parts of walnut shell granules, 5 parts of heartwood powder, 2 parts of citric acid, 3 parts of sodium bicarbonate, 4 parts of sodium carboxymethyl cellulose, 4 parts of medical stone powder;

[0030] Wherein, the split wood powder is obtained through the following pretreatment: the split wood is added into water according to the material-to-liquid ratio of 1g:0.3L, decocted at 100°C for 30min, cooled to room temperature, and then added with the water Continue soaking the same volume of shiitake mushroom liquid for 4 hours, then ultrasonically treat it for 25 minutes under the conditions of ultrasonic power 400W and ultrasonic frequency 40KHz, filter, vacuum-dry the filter residue at 45°C until the water content is 8%, and pulverize;

[0031] The particle size distribution ratio of the walnut shell particles is as follows: passing through a sieve of 8-14 mesh; p...

Embodiment 2

[0039] 1. A kind of non-caking type cat litter, is made up of the raw material of following weight part:

[0040] 100 parts of walnut shell granules, 12 parts of heartwood powder, 7 parts of citric acid, 8 parts of sodium bicarbonate, 9 parts of sodium carboxymethyl cellulose, 10 parts of medical stone powder;

[0041] Wherein, the split wood powder is obtained through the following pretreatment: the split wood is added into water according to the material-to-liquid ratio of 1g:0.3L, decocted at 100°C for 50min, cooled to room temperature, and then added with the water Continue soaking the same volume of shiitake mushroom liquid for 5 hours, then ultrasonically treat it for 15 minutes under the conditions of ultrasonic power 400W and ultrasonic frequency 40KHz, filter, vacuum-dry the filter residue at 60°C until the water content is 10%, and pulverize;

[0042] The particle size distribution ratio of the walnut shell particles is as follows: passing through a sieve of 8-14 mes...

Embodiment 3

[0050] 1. A kind of non-caking type cat litter, is made up of the raw material of following weight part:

[0051] 90 parts of walnut shell granules, 7 parts of heartwood powder, 3 parts of citric acid, 5 parts of sodium bicarbonate, 6 parts of sodium carboxymethyl cellulose, 6 parts of medical stone powder;

[0052] Wherein, the split wood powder is obtained through the following pretreatment: the split wood is added into water according to the material-to-liquid ratio of 1g:0.3L, decocted at 100°C for 40min, cooled to room temperature, and then added with the water Continue soaking the same volume of shiitake mushroom liquid for 4.5 hours, then ultrasonically treat it for 20 minutes under the conditions of ultrasonic power 400W and ultrasonic frequency 40KHz, filter, vacuum-dry the filter residue at 55°C until the water content is 9%, and pulverize;

[0053] The particle size distribution ratio of the walnut shell particles is as follows: passing through a sieve of 8-14 mesh;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com