Method for replacing soybean meal and DDGS with cured corn steep liquor

A technology of corn steep liquor and soybean meal, which is applied in the field of waste resource utilization to achieve the effects of enriching the market, simple technological process and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

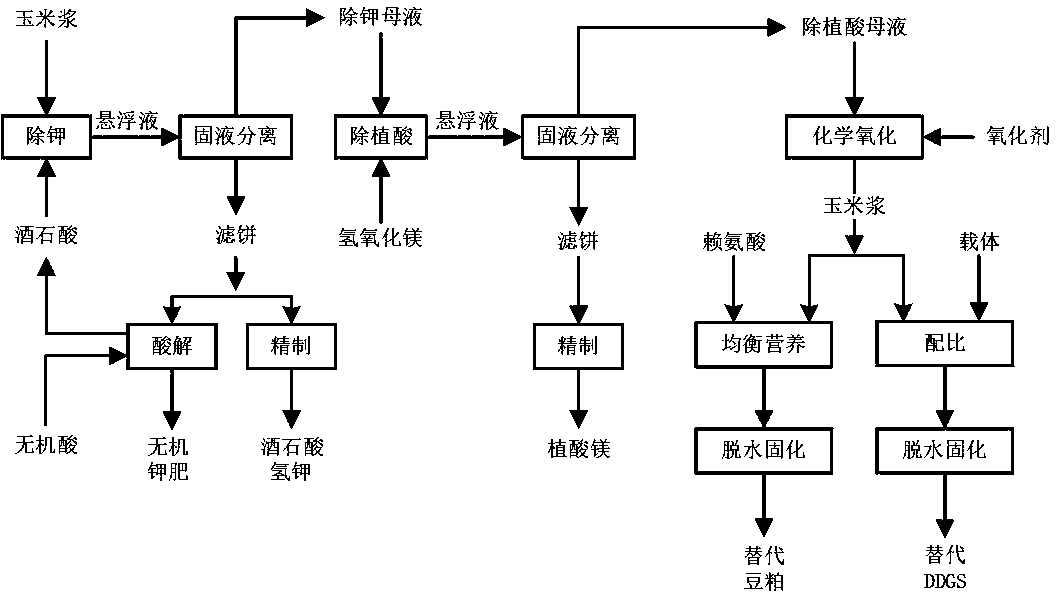

Method used

Image

Examples

Embodiment 1

[0036] Embodiment one: replace soybean meal

[0037] (1) Remove excess potassium from corn steep liquor. At room temperature, take 1000 g of corn steep liquor and add 30 g of tartaric acid to obtain a suspension; separate the suspension from solid and liquid to obtain 80 g of filter cake and 950 g of potassium-removing mother liquor; wash and dry the filter cake to obtain 50 g of potassium hydrogen tartrate.

[0038] (2) Remove phytic acid from corn steep liquor. Add 45g of magnesium hydroxide solids to the 950g potassium-removing mother liquor obtained in step (1) to obtain a suspension whose pH was measured to be 5.0; separate the suspension from solid-liquid to obtain 120g of filter cake and 875g of phytic acid-removing mother liquor; the filter cake was washed and dried to obtain 92 g of magnesium phytate.

[0039] (3) Removal of sulfite and aspergillus in corn steep liquor. Add 3 ml of industrial hydrogen peroxide to the 875 g of phytic acid removal mother liquor obtaine...

Embodiment 2

[0042] Example 2: Substitute for DDGS

[0043] (1) Removal of excess potassium in corn steep liquor. At room temperature, take 1000 g of corn steep liquor and add 30 g of tartaric acid to obtain a suspension; separate the suspension from solid and liquid to obtain 80 g of filter cake and 950 g of potassium-removing mother liquor; wash and dry the filter cake to obtain 50 g of potassium hydrogen tartrate.

[0044] (2) Removal of phytic acid in corn steep liquor. Add 45g of magnesium hydroxide solids to the 950g potassium-removing mother liquor obtained in step (1) to obtain a suspension whose pH was measured to be 5.0; separate the suspension from solid-liquid to obtain 120g of filter cake and 875g of phytic acid-removing mother liquor; the filter cake was washed and dried to obtain 92 g of magnesium phytate.

[0045] (3) Removal of sulfite and aspergillus in corn steep liquor. Add 3 ml of industrial hydrogen peroxide to the 875 g of phytic acid removal mother liquor obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com