Conjugated linoleic acid glyceride microcapsule powder and preparation method thereof

A conjugated linoleic acid glyceride and conjugated linoleic acid glyceride technology, which is applied in the field of conjugated linoleic acid glyceride microcapsule powder and its preparation, can solve problems such as complex formulation components, achieve excellent stability, pH Wide range of adaptation, simple and controllable production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

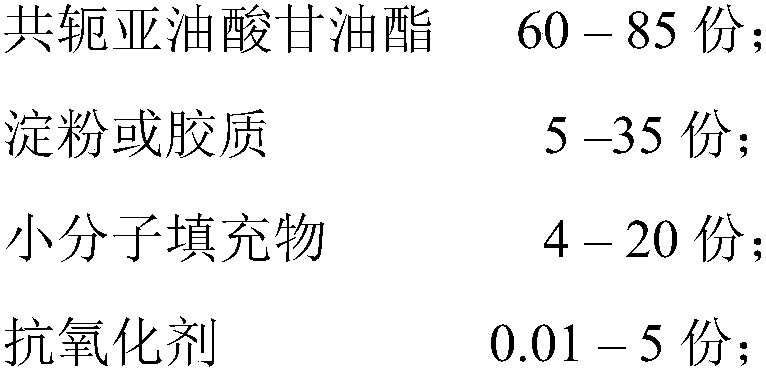

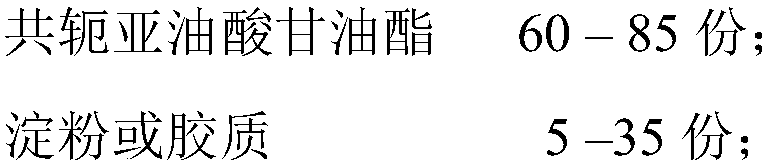

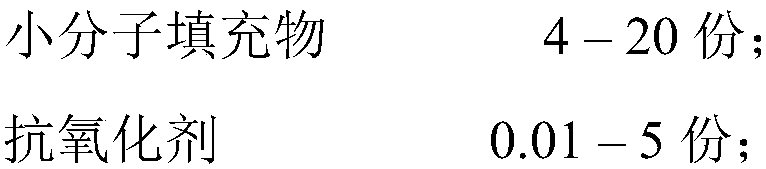

[0020] The present invention provides a kind of conjugated linoleic acid glyceride microcapsule powder and preparation method thereof, in the specific embodiment of described method, comprise the following steps:

[0021] (1) Prepare raw materials:

[0022] (2) Dissolve starch, colloid, and small molecule fillers in water at 50-60°C, and then cool the system down to 0-20°C;

[0023] (3) Add the water-phase antioxidant to the system of (2), and stir at 0-20°C until completely dissolved to obtain the water phase;

[0024] (4) Add the oil phase antioxidant into the conjugated linoleic acid glyceride, and stir at 10-20°C until completely dissolved to obtain the oil phase;

[0025] (5) Add the oil phase to the water phase, and under the condition of controlling the temperature of the system at 0-20°C, shear emulsify for 0.5-1.5h, and then homogenize under high pressure at 45-90MPa for 1-3 times to obtain an emulsion;

[0026] (6) Spray-dry the emulsion prepared in step (5): the i...

Embodiment 1

[0035] Weigh 300g of water into a 1000mL beaker at a water temperature of 50°C, add 75g of gum arabic, 25.2g of maltooligosaccharide and 0.3g of sodium ascorbate into it, stir until completely dissolved, then cool the water phase to 20°C for later use. Weigh 1.5 g of mixed tocopherols into 195 g of conjugated linoleic acid glycerides, and keep the oil phase at 20° C. and stir evenly. Pour the oil phase into the water phase, shear and emulsify at a temperature of 20°C for 1 hour, and homogenize twice under high pressure with a homogenization pressure of 90 MPa. Then carry out spray drying, the air inlet temperature is 180°C, and the outlet air temperature is 75°C. The obtained conjugated linoleic acid glyceride microcapsule powder is recorded as CLA TG CWD-1.

Embodiment 2

[0037] Weigh 500g of water into a 2000mL beaker at a temperature of 40°C, add 100g of modified starch, 38.1g of resistant dextrin, 1g of ascorbic acid and 4g of sodium ascorbate into it, stir until completely dissolved, then cool the water phase to 15°C for later use. Weigh 1.9g of mixed tocopherols into 350g of conjugated glycerol linoleate, keep the oil phase at 25°C and stir evenly, then cool down to 15°C. Pour the oil phase into the water phase, shear and emulsify for 1.5 hours at a temperature of 15°C, and homogenize twice under high pressure with a homogenization pressure of 95 MPa. Then carry out spray drying, the air inlet temperature is 170°C, and the outlet air temperature is 84°C. Mix 3g of calcium silicate as an anticaking agent to finally obtain conjugated linoleic acid glyceride microcapsule powder, which is denoted as CLA TG CWD-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com