Preparation method of hemostatic sponge and hemostatic sponge prepared thereby

A technology of hemostatic sponge and oxidized cellulose, which is applied in the field of preparation of hemostatic sponge and hemostatic sponge, which can solve the problems of poor tissue adhesion, virus infection, wound inflammation, etc., and achieve the effect of high porosity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

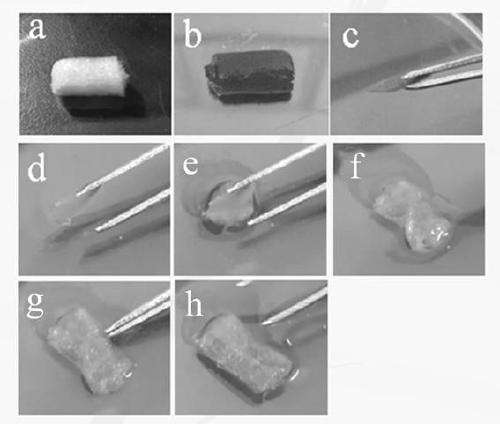

[0053] A preparation method of hemostatic sponge, comprising the following steps:

[0054] (1) Disperse the oxidized cellulose powder in water to make a mass fraction of 0.5wt% oxidized cellulose dispersion, and then carry out high-pressure homogenization treatment to the oxidized cellulose dispersion to obtain a nano-oxidized cellulose suspension; wherein, the The pressure of the high-pressure homogenization treatment is 1000 bar, the number of high-pressure homogenization treatment is 30 times, and the temperature of the oxidized cellulose dispersion is controlled not to exceed 70°C during the high-pressure homogenization treatment;

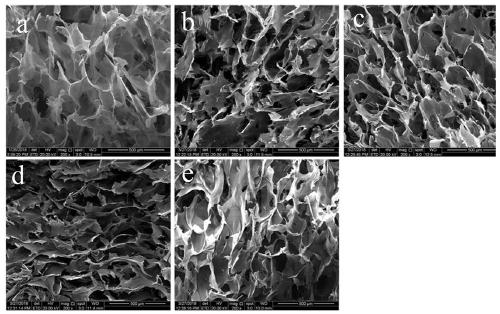

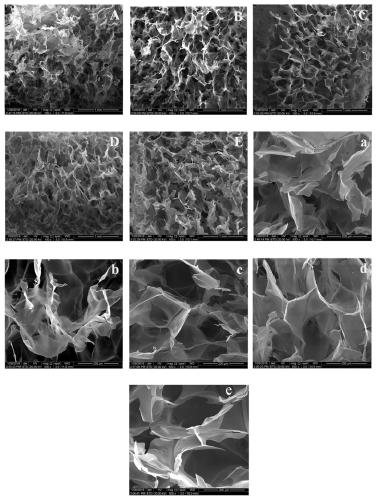

[0055] (2) Concentrating the nano-oxidized cellulose suspension treated in step (1) to obtain a concentrated nano-oxidized cellulose suspension with a mass fraction of 1 wt%, and placing the concentrated nano-oxidized cellulose suspension in a mould, Perform 5 freeze-thaw cycles to obtain nanocellulose hydrogel, freeze and shape the nanocellulo...

Embodiment 2

[0057] The content of Example 2 is basically the same as that of Example 1, except that the mass fraction of the concentrated nano-oxidized cellulose suspension is 0.6 wt%.

Embodiment 3

[0059] The content of Example 3 is basically the same as that of Example 1, except that the mass fraction of the concentrated nano-oxidized cellulose suspension is 2 wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com