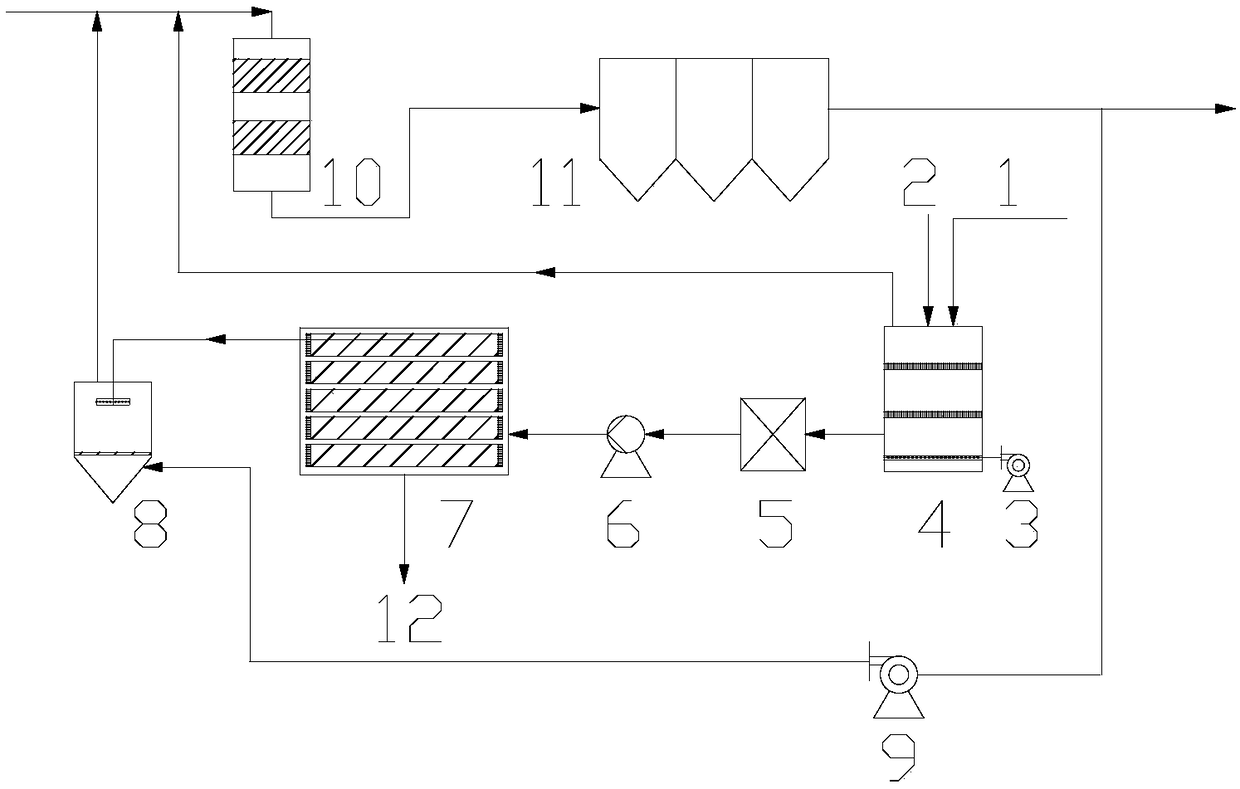

Technology and device for zero-drainage of desulfurization wastewater

A technology for desulfurization wastewater and zero discharge, applied in degassed water/sewage treatment, gaseous effluent wastewater treatment, water/sewage treatment, etc., can solve the problem of increasing investment and operating costs of reverse osmosis devices, and high investment and operating costs of MVR devices , affect the normal operation of the reverse osmosis membrane and other issues, to achieve the effect of ammonia nitrogen recycling, improve operation stability and service life, reduce the amount of hazardous waste and treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A thermal power plant, two 135MW units flue gas desulfurization waste water zero discharge project adopts this process, the waste water volume is 22.3m 3 / h, suspended matter content 2.13%, soluble salt content 2.78%, raw water pH value 5.87, deamination tower aeration air volume gas-liquid volume ratio is 270, aeration hole perforation gas velocity is 18m / s, opening aperture is 10mm The residence time of the wastewater in the deamination tower is 12min, and the control range of the pH value of the wastewater is 9.6 during the stripping; The salt content is 18.6%, the salt content of the effluent fresh water is 0.02%, and the water consumption of the reverse osmosis device is 18.8m 3 / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com