Organosilicon polymerization curing agent, and applications and application method thereof

A polymerization curing, silicone technology, applied in the direction of radioactive purification, nuclear engineering, etc., can solve the problems of long curing time, low modulus, limited types, etc., achieve good aging resistance and biodegradation resistance, good radiation stability, The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Radioactive waste resin (particle size: 0.3-1.5mm) 40wt%, viscosity 1000cp epoxy-containing dimethyl silicone oil 57wt%, polyetheramine MA340 (Wuxi Akeli Technology Co., Ltd.) 1.5wt%, DPM-300.05wt %, aluminum hydroxide 1.45wt%, the above materials were mixed and stirred evenly at room temperature, and left to stand for 3 days, and the performance of the solidified body was tested according to the standards or methods in Table 1, and all of them could meet or exceed the index requirements.

Embodiment 2

[0042]Radioactive waste resin (0.3 ~ 1.5mm in particle size) 50wt%, viscosity 1500cp methyl trifluoropropyl silicone oil containing epoxy group 43.9%, modified fatty amine 1522B (Wuxi Huilong Electronic Materials Co., Ltd.) 3wt%, liquid imidazole 0.1wt%, magnesium hydroxide 3wt%, the above materials were mixed and stirred evenly at room temperature, and left to stand for 3 days, and the performance of the solidified body was tested according to the standards or methods in Table 1, all of which could meet or exceed the index requirements.

Embodiment 3

[0044] Radioactive salt block (0.3-1.5mm particle size) 60wt%, viscosity 1000cp methyl phenyl silicone oil containing epoxy group 37wt%, polyetheramine MA240 (Wuxi Akeli Technology Co., Ltd.) 1.99wt%, DMP- 300.01wt%, magnesium hydroxide 1wt%, the above materials were mixed and stirred evenly at room temperature, left to stand for 3 days, and the performance of the solidified body was tested according to the standards or methods in Table 1, all of which could meet or exceed the index requirements.

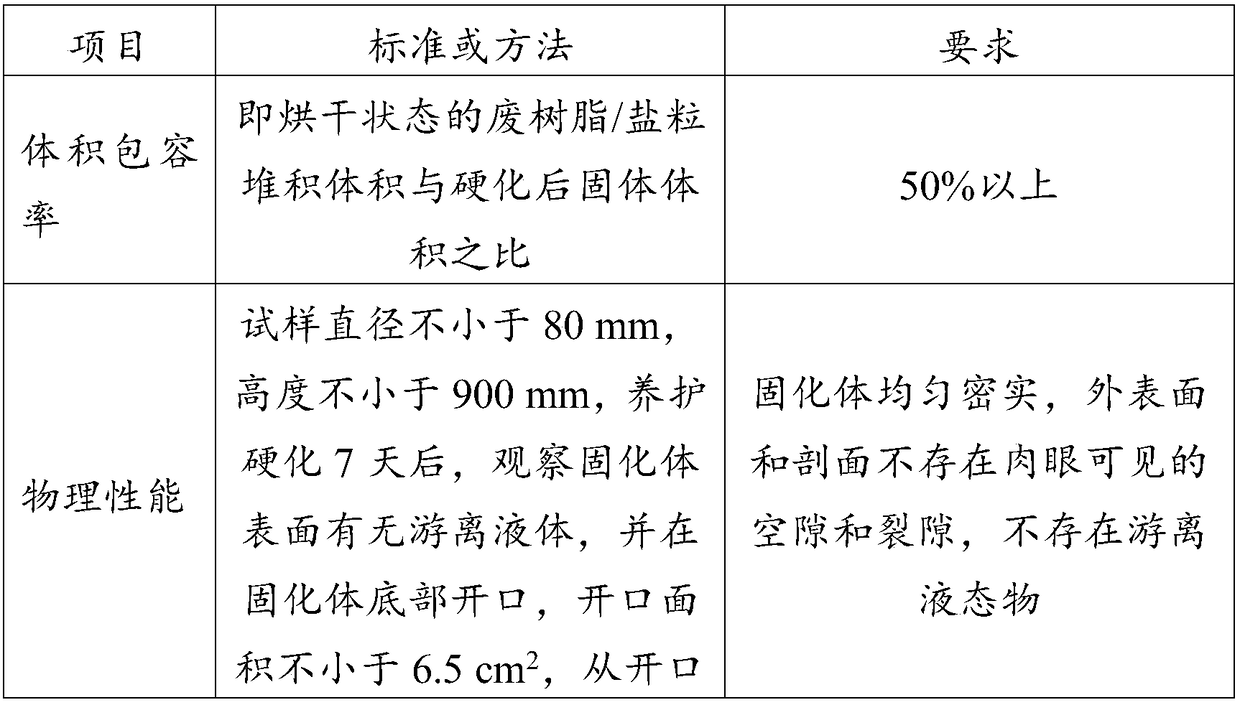

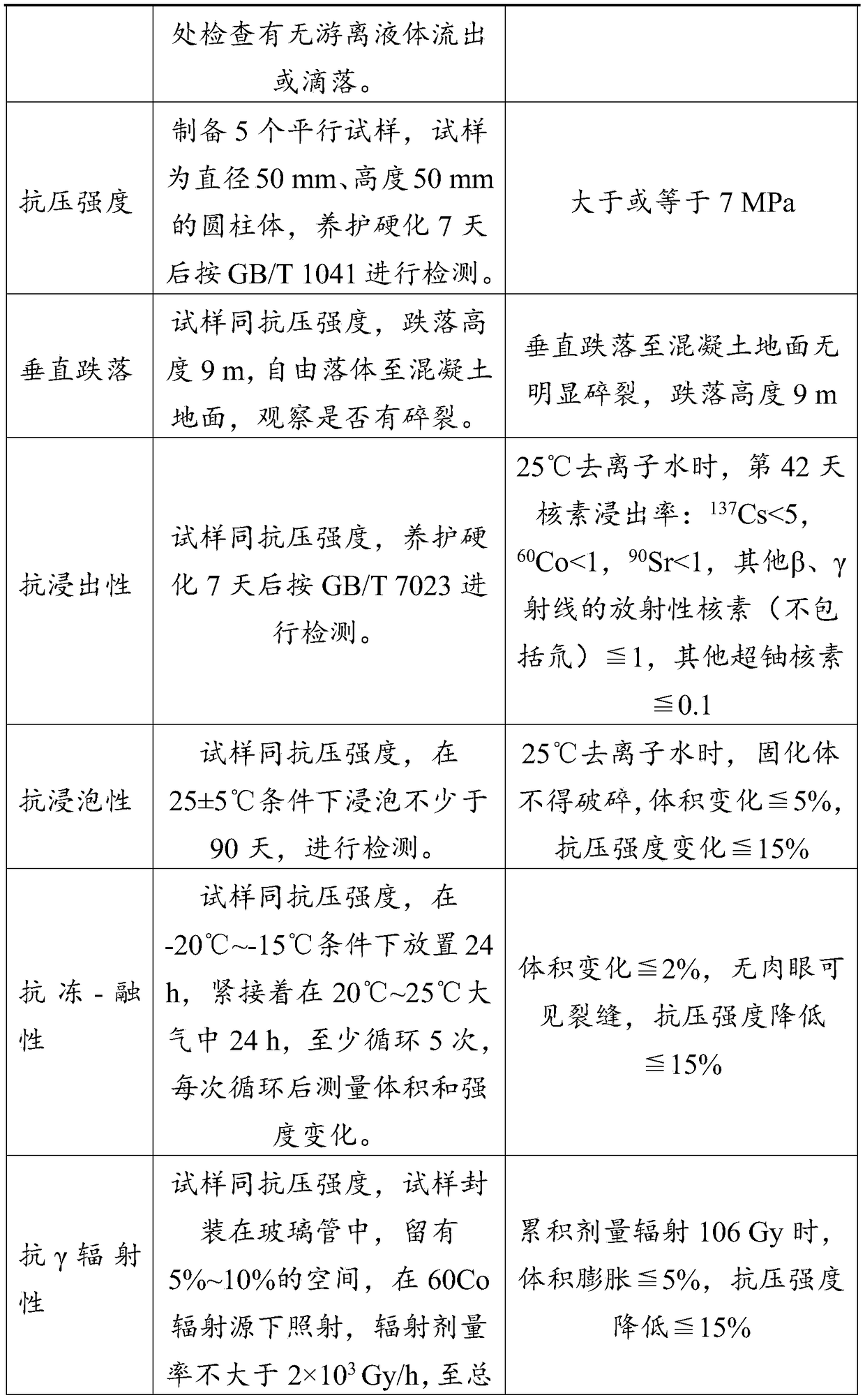

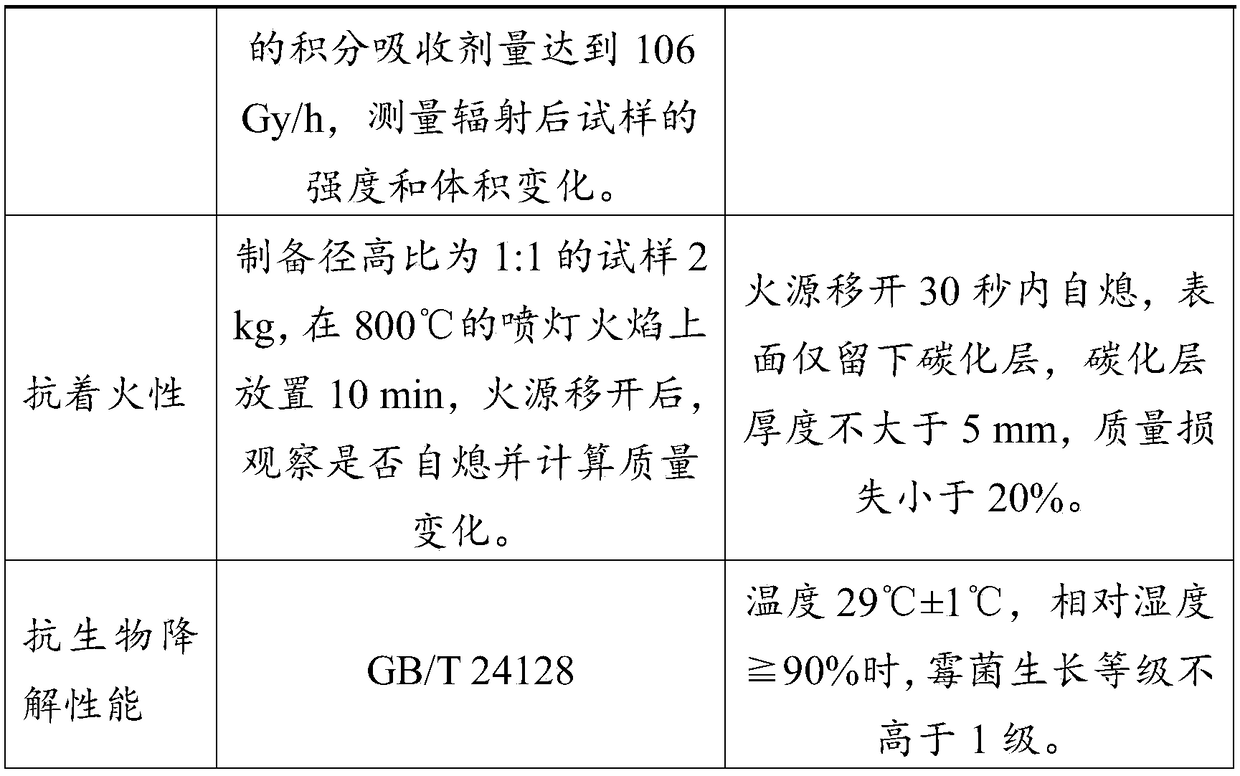

[0045] Table 1 Solid detection standards and requirements

[0046]

[0047]

[0048]

[0049] It can be seen from the above examples that the present invention provides a silicone polymerization curing agent, which contains 37-57 parts of epoxy silicone oil, 1-5 parts of organic amine curing agent, and 0.01-0.1 part of curing accelerator. When the organosilicon polymerization curing agent provided by the present invention is in use, the epoxy group in the epoxy silicone oil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com