Separation and purification method of xylobiose and xylotriose and application thereof

A technology for separation and purification of xylotriose, applied in chemical instruments and methods, disaccharides, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

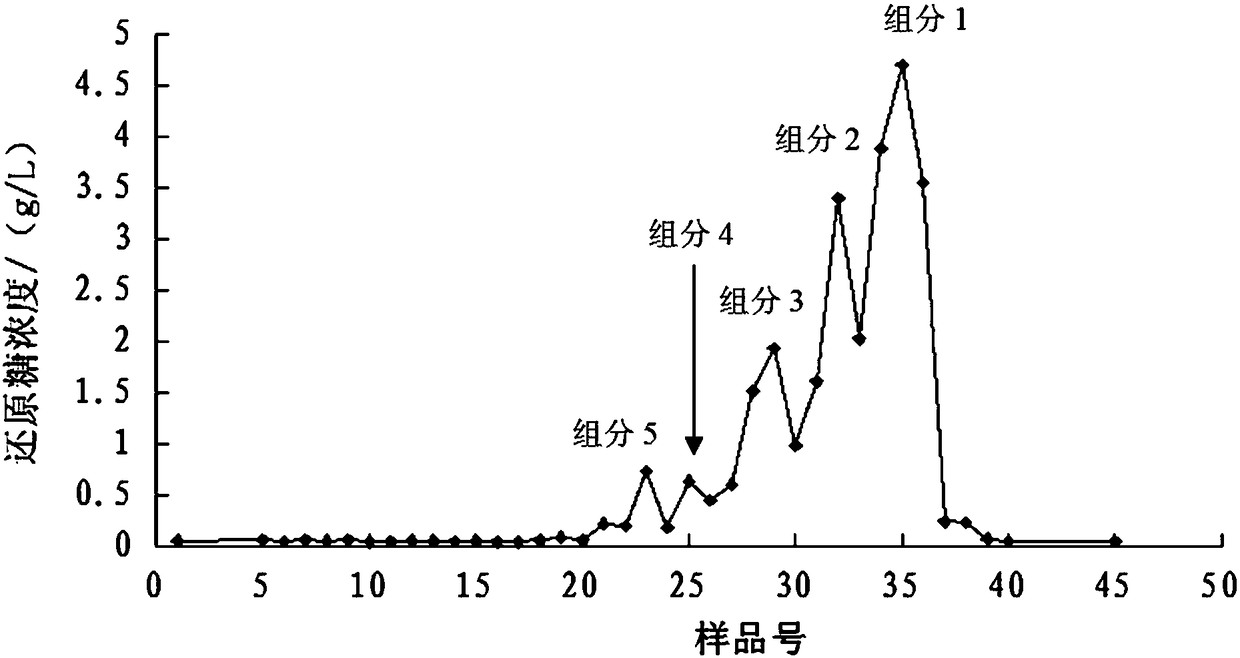

[0045] Coarse separation of xylobiose and xylotriose in embodiment 1 xylooligosaccharides

[0046] Prepare xylo-oligosaccharide powder into 500g / L xylo-oligosaccharide solution, centrifuge at 4000r / min for 10min at high speed, take its supernatant (repeat several times until the supernatant is clear and transparent), and adjust the pH to 6-8. Store the processed xylo-oligosaccharide solution in a refrigerator at 4°C until use. A protein liquid chromatography system (AKTA purifier system, GE Company) was used for crude separation of single xylo-oligosaccharide components. The chromatographic column is 60×2.5cm I.D., the chromatographic medium is polyacrylamide gel Bio-Gel P-2, eluted with degassed ultrapure water, the elution rate is 60mL / h, the column temperature is 35°C, and the eluent Collect 6 mL per tube and collect 95 tubes.

[0047] 1. Determination of single component reducing sugar concentration

[0048] Use the DNS (3,5-dinitrosalicylic acid) method to measure the ...

Embodiment 2

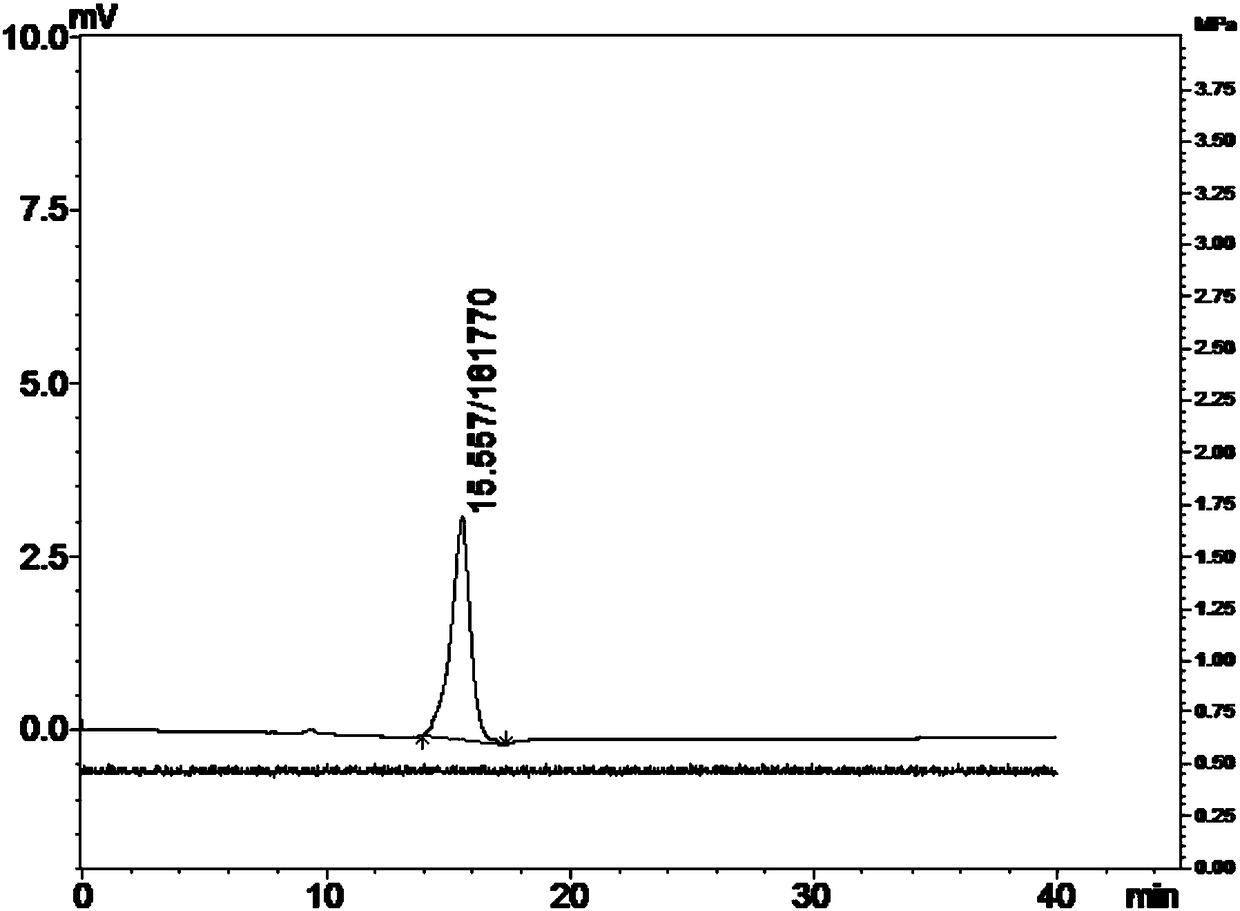

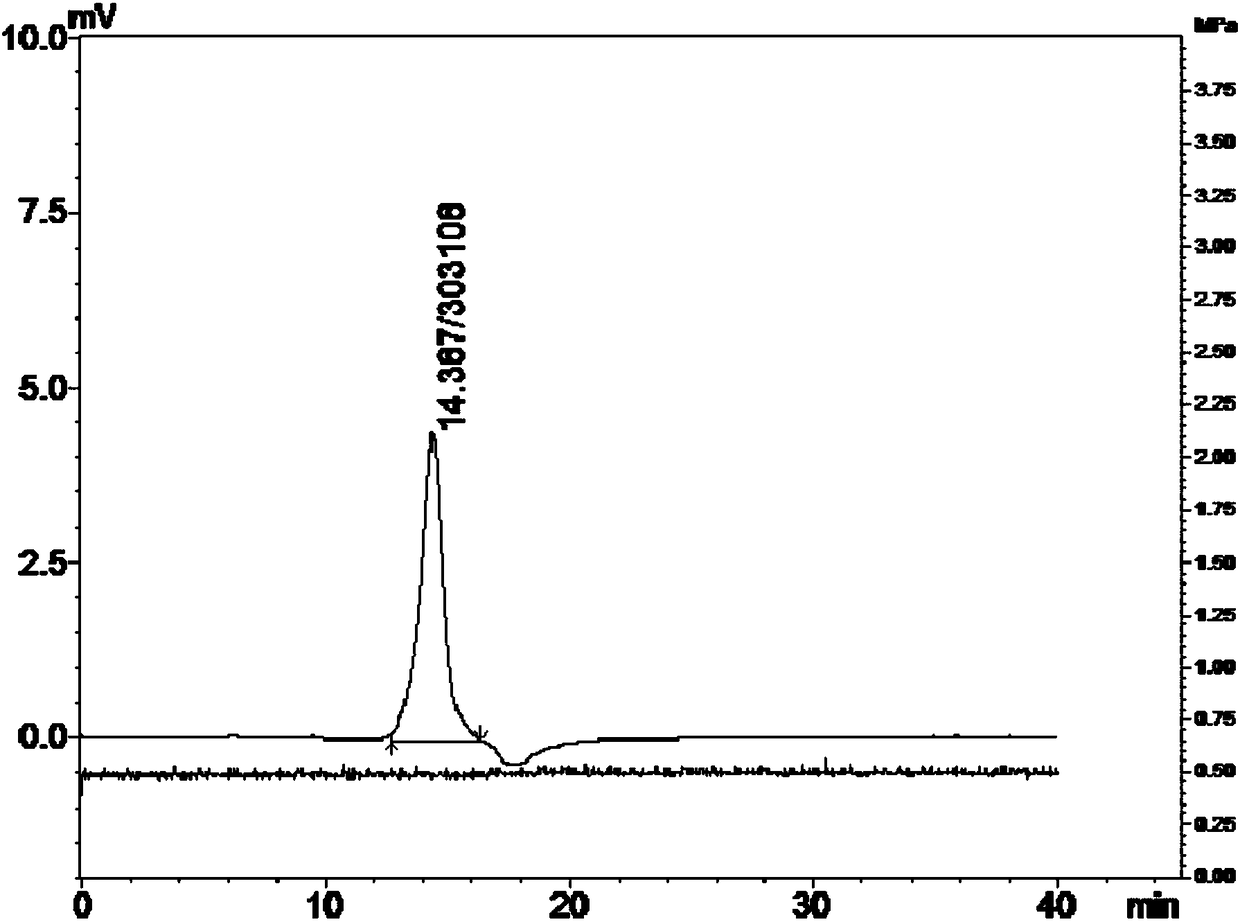

[0060] Secondary separation of xylobiose and xylotriose in xylooligosaccharides in embodiment 2

[0061] The final xylobiose and xylotriose liquids obtained in Example 1 are subjected to secondary separation respectively, and the secondary separation adopts a constant flow pump (HUXI-Pump) and an automatic collector (BSZ-100); the chromatographic column is 100× 1.2cm I.D., the chromatographic medium is polyacrylamide gel Bio-Gel P-2, eluted with degassed ultrapure water, the elution rate is 12mL / h, the eluent is collected in 1.5mL per tube, and 95 tubes are collected. The determination method and steps are the same as step 1, and the concentration of reducing sugar in the collection tube is measured by DNS method, and the secondary separation and elution curve is drawn.

[0062] 1. Determination of single component reducing sugar concentration

[0063] The results of reducing sugar concentration measurement after the secondary separation of xylobiose are as follows: Figure ...

Embodiment 3

[0066] Example 3 Effect of xylobiose and xylotriose on chicken intestinal bacteria

[0067] 1. Experimental design

[0068] Thirty healthy AA chicks with similar body weight at 1 day were selected and randomly divided into 3 treatment groups, each treatment group had 5 replicates, and each replicate had 2 chickens. The three treatment groups were control group, xylobiose group and xylotriose group. All the chicks in the experiment ate the basic diet and were treated by gavage. The concentration of monosaccharide in the treatment group was 6.0g / L, and the perfusion meter was 0.5mL, once a day at 9 o'clock in the morning, for 7 consecutive days. The test broilers were kept in the same chicken house, with ad libitum feeding and drinking, 24h continuous light, immunization procedures and other management were carried out as usual.

[0069] 2. Sample collection

[0070]When the chicks were reared on the 8th day of age, all the chicks in each treatment group were slaughtered, dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com