Probiotic beverage for regulating intestinal flora and preparation method thereof

A technology of probiotic beverages and intestinal flora, applied to bacteria, lactobacilli, bifidobacteria, etc. used in food preparation, can solve problems such as unfavorable acceptance, impact on equipment use, and rapid overflow of unfavorable active ingredients, etc., to achieve Improving immunity, lowering cholesterol, and improving the effect of flat and salty taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

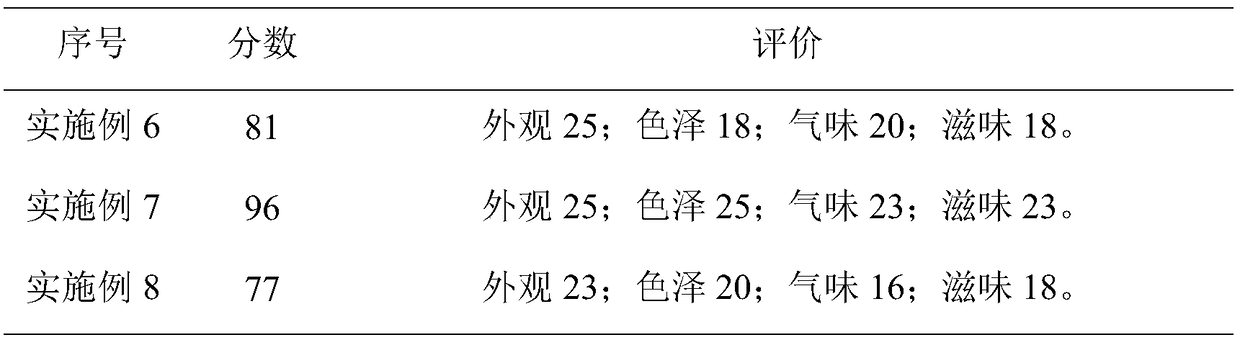

Examples

preparation example Construction

[0048] The present invention also provides a method for preparing the probiotic beverage for regulating intestinal flora, comprising the following steps:

[0049] Step 1: Weigh the following components by weight: 0.2-0.4 parts of compound probiotics, 75-85 parts of sweet potato juice, 0.4-0.8 parts of fructose, 2-5 parts of highland barley powder, 8-10 parts of oligosaccharides, and wolfberry juice 8-10 parts, 0.5-2 parts of pears, 0.5-2 parts of apples and 0.3-0.8 parts of cherries;

[0050] Step 2: Mix the weighed sweet potato juice and fructose and stir evenly to obtain the first mixed solution;

[0051] Step 3: uniformly mix the weighed wolfberry juice and oligosaccharides with 78-85 parts by weight of water, store at low temperature for later use, and obtain the second mixed solution;

[0052] Step 4: Mix the weighed highland barley powder and the obtained second mixed solution, stir evenly, boil on low heat for 15-20 minutes, and then boil for 2-4 minutes to obtain high...

Embodiment 1

[0070] The preparation of sweet potato juice comprises the steps:

[0071] Step 1: washing and peeling the sweet potatoes, slicing them, drying them at 45°C, and grinding them into powder to obtain sweet potato flour;

[0072] Step 2: Mix the obtained sweet potato powder with 0.01 times of mixed enzyme and 8 times of distilled water, and enzymolyze at 28°C for 1.5 hours to obtain an enzymolysis solution;

[0073] Step 3: Centrifuge the obtained enzymatic hydrolyzate to obtain the first supernatant, sterilize the obtained first supernatant by high-temperature steam at 121°C for 10 seconds, and cool to 30°C to obtain sweet potato juice;

[0074] Wherein, the mixed enzyme is composed of amylase, pectinase and papain in a mass ratio of 2:0.5:0.5.

[0075] The sweet potato juice prepared by the above method has a protein content of 0.44g / 100g.

Embodiment 2

[0077] Step 1: washing and peeling the sweet potatoes, slicing them, drying them at 45°C, and grinding them into powder to obtain sweet potato flour;

[0078] Step 2: Mix the obtained sweet potato powder with 0.02 times of mixed enzyme and 10 times of distilled water, and perform enzymatic hydrolysis for 2 hours to obtain an enzymatic hydrolysis solution;

[0079] Step 3: Centrifuge the obtained enzymatic hydrolyzate to obtain the first supernatant, sterilize the obtained first supernatant by high-temperature steam at 121°C for 15 seconds, and cool to 35°C to obtain sweet potato juice;

[0080] Wherein, the mixed enzyme is composed of amylase, pectinase and papain in a mass ratio of 2:1:1.

[0081] The sweet potato juice prepared by the above method has a protein content of 0.46g / 100g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com