Preparation method of mesoporous silicon dioxide nanomaterial with fluorescent imaging and drug loading functions

A technology of mesoporous silica and fluorescence imaging, which is applied in the direction of silica, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of complex preparation methods and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

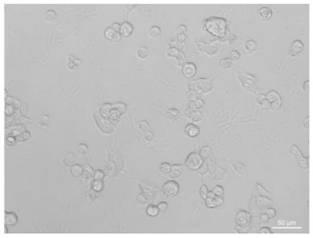

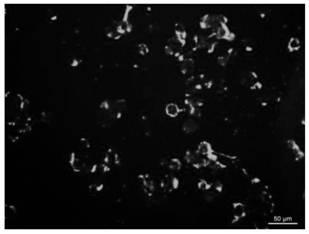

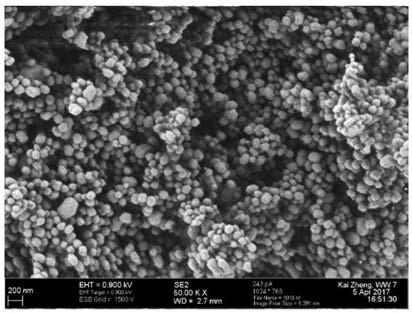

[0024] Step 1, preparation of mesoporous silica nanoparticles.

[0025] Weigh 250 mg of cetyltrimethylammonium bromide and dissolve it in 120 mL of deionized water, then add 0.87 mL of 1.0 mol / L sodium hydroxide solution, and stir vigorously at 60°C for 20 min. After cetyltrimethylammonium bromide was completely dissolved, 1.0 mL of ethyl orthosilicate was slowly added, and stirring was continued for 1 hour. After the reaction, the product was cooled to room temperature, centrifuged, and washed three times with deionized water and ethanol. Finally, the ethanol solution containing ammonium nitrate with a mass volume ratio of 5 g / L was refluxed for 12 hours to remove the template agent, washed three times with deionized water and ethanol in turn, and dried in vacuum at 60 °C to constant weight to obtain mesoporous silica. Nanoparticles, codenamed MSN.

[0026] Step 2: Amination modification is performed on the surface of the mesoporous silica nanoparticles.

[0027] Weigh 100...

Embodiment 2

[0033]Step 1, preparation of mesoporous silica nanoparticles.

[0034] Weigh 300mg of cetyltrimethylammonium bromide and dissolve it in 120mL of deionized water, then add 0.98mL of 1.5mol / L sodium hydroxide solution, and stir vigorously at 70°C for 25min. After cetyltrimethylammonium bromide was completely dissolved, 1.5 mL of ethyl orthosilicate was slowly added, and stirring was continued for 1.5 hours. After the reaction, the product was cooled to room temperature, centrifuged, and washed four times with deionized water and ethanol. Finally, the ethanol solution containing ammonium nitrate with a mass volume ratio of 6 g / L was refluxed for 18 hours to remove the template agent, washed with deionized water and absolute ethanol for 4 times, and vacuum-dried at 70 °C to constant weight to obtain the mesoporous Silicon oxide nanoparticles, code-named MSN.

[0035] Step 2: Amination modification is performed on the surface of the mesoporous silica nanoparticles.

[0036] Weig...

Embodiment 3

[0041] Step 1, preparation of mesoporous silica nanoparticles.

[0042] Weigh 350mg of cetyltrimethylammonium bromide and dissolve it in 200mL of deionized water, then add 1.85mL of 2.0mol / L sodium hydroxide solution, and stir vigorously at 80°C for 30min. After cetyltrimethylammonium bromide was completely dissolved, 3.0 mL of ethyl orthosilicate was slowly added, and stirring was continued for 2 hours. After the reaction, the product was cooled to room temperature, centrifuged, and washed five times with deionized water and ethanol in sequence. Finally, the ethanol solution containing ammonium nitrate with a mass volume ratio of 7 g / L was refluxed for 24 hours to remove the template agent, washed with deionized water and absolute ethanol for 5 times, and vacuum-dried at 80 °C to constant weight to obtain the mesoporous bismuth Silicon oxide nanoparticles, code-named MSN.

[0043] Step 2: Amination modification is performed on the surface of the mesoporous silica nanopartic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com