Graphene oxide composite flocculant for sewage treatment and preparation method of graphene oxide composite flocculant for sewage treatment

A graphene composite, sewage treatment technology, applied in water/sewage treatment, water treatment parameter control, adsorbed water/sewage treatment and other directions, can solve problems such as application scope limitation, mutagenic, carcinogenic, etc. The preparation method is simple and the effect of fast adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A kind of preparation method of the graphene oxide composite flocculant that is used for sewage treatment provided by the invention, it specifically comprises the following steps:

[0024] 1) Preparation of liquid A: respectively prepare graphene oxide hydrosol with volume concentration of 1-5mg / mL, polyacrylic acid aqueous solution with molar concentration of 0.2-2M and sodium carbonate aqueous solution with molar concentration of 0.1-0.5M, and then prepare Pour the polyacrylic acid aqueous solution into the graphene oxide sol, and stir until the solution is evenly mixed;

[0025] 2) Pour the prepared sodium carbonate aqueous solution into the mixed solution in step 1), stir until the solution is evenly mixed to obtain A solution, and bottle it for later use;

[0026] 3) Prepare a calcium chloride solution with a molar concentration of 0.2-2M to obtain a solution B, which is bottled for use.

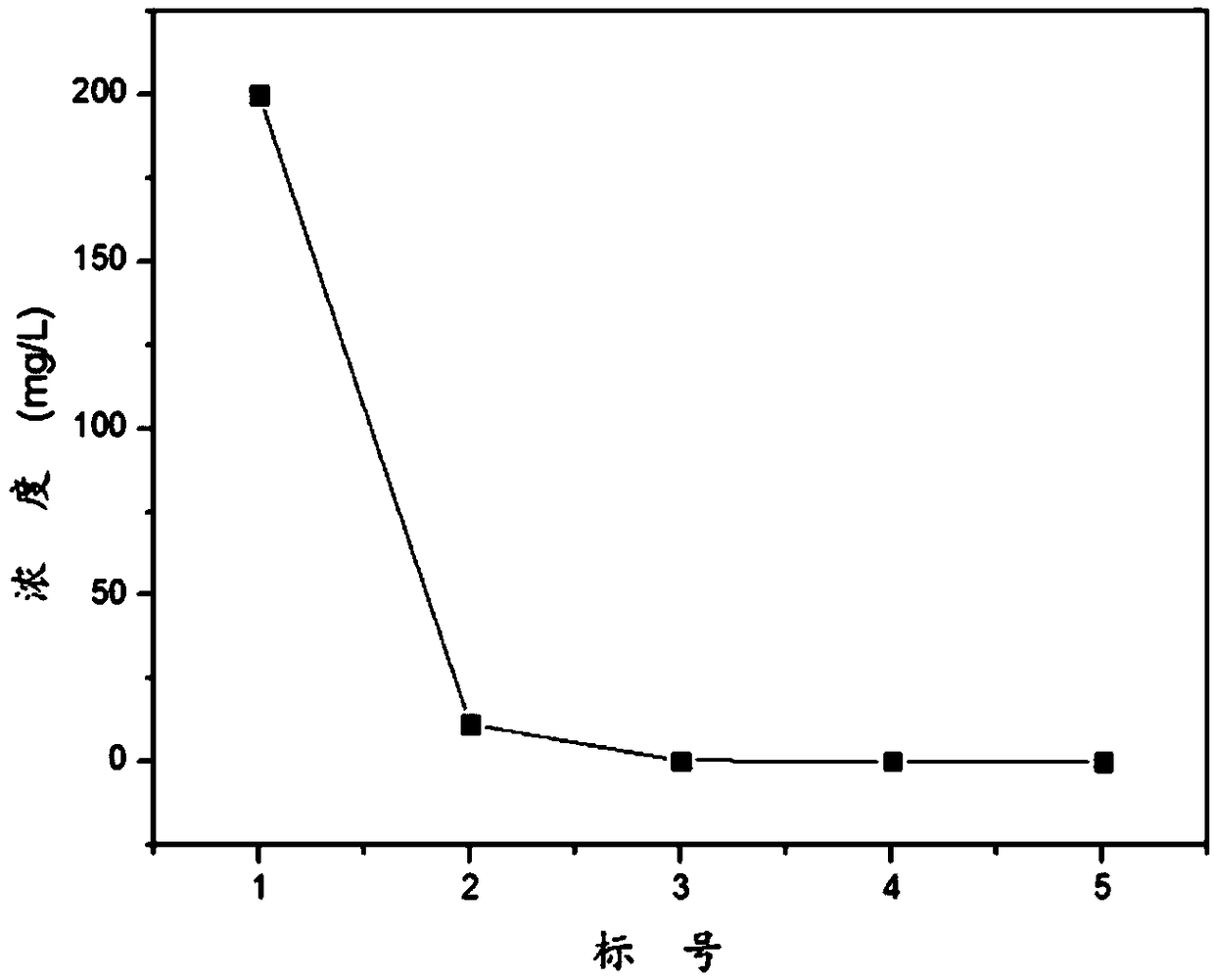

Embodiment 1

[0044] (1) Preparation of precursor solution: prepare 100mL of GO hydrosol with a concentration of 1mg / mL; prepare 100mL of polyacrylic acid solution with a concentration of 0.4M; prepare 100mL of sodium carbonate solution with a concentration of 0.1M; prepare 100mL of calcium chloride solution with a concentration of 0.4M; After preparing the solution, ultrasonically disperse for 30 minutes and set aside;

[0045] (2) Preparation of liquid A and liquid B: take 40mL of GO hydrosol, 30mL of polyacrylic acid, and 20mL of sodium carbonate and stir them evenly to prepare liquid A. The volume ratio of graphene oxide hydrosol, polyacrylic acid, and sodium carbonate is 1: 0.75:0.5; take 20mL of calcium carbonate aqueous solution to be liquid B, the volume ratio of liquid A to liquid B is 4.5:1; first pour liquid A into the sewage and stir for 5 minutes, then pour liquid B and stir for 5 minutes, then the Cationic dyes, heavy metal ions, and floating matter are quickly flocculated and...

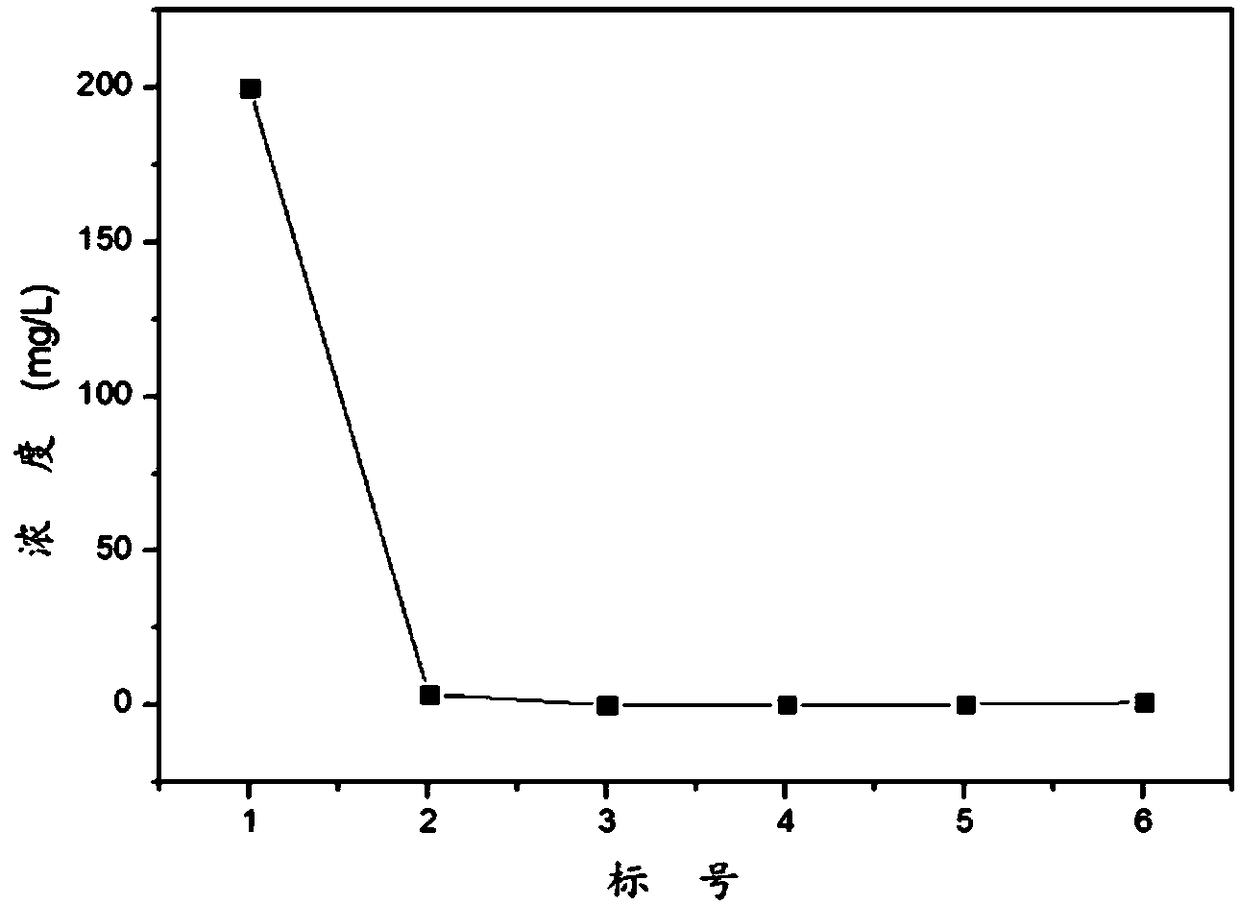

Embodiment 2

[0047] (1) Preparation of precursor solution: prepare 100mL of GO hydrosol with a concentration of 2mg / mL; prepare 100mL of polyacrylic acid solution with a concentration of 0.5M; prepare 100mL of sodium carbonate solution with a concentration of 0.2M; prepare 100mL of calcium chloride solution with a concentration of 0.5M; After preparing the solution, ultrasonically disperse for 30 minutes and set aside;

[0048] (2) Preparation of liquid A and liquid B: take 40mL of GO hydrosol, 10mL of polyacrylic acid, and 10mL of sodium carbonate and stir them evenly to prepare liquid A. The volume ratio of graphene oxide hydrosol, polyacrylic acid, and sodium carbonate is 1: 0.25:0.25; take 10mL of calcium carbonate as liquid B, the volume ratio of liquid A to liquid B is 6:1; first pour liquid A into the sewage and stir for 5 minutes, then pour liquid B and stir for 5 minutes, the cations in the sewage Dyes, heavy metal ions, and floating matter are quickly flocculated and settled, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com