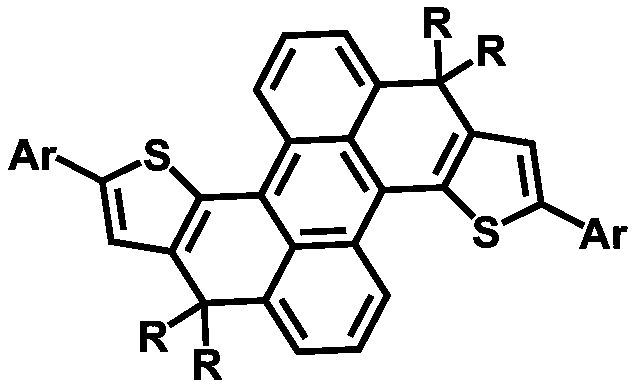

A class of electroluminescent materials containing polar substituent group anthracene derivatives and its preparation method and application

A technology of electroluminescent materials and polar substituents, applied in the direction of luminescent materials, chemical instruments and methods, circuits, etc., can solve the problems of reducing the photoelectric performance of devices, not easy to form amorphous films, and restricting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] 1. Preparation of anthracene derivative monomers containing polar substituent groups

[0087] Preparation of Thiophene-3-Carboxyl Chloride

[0088] In a 500mL three-necked flask, thiophene-3-carboxylic acid (12.8g, 0.1mol) was dissolved in N,N-dimethylformamide, and 20ml of thionyl chloride was added dropwise to the reaction solution, and stirred at room temperature for 12 hours Afterwards, the reaction was stopped, the reaction was quenched with water, extracted with dichloromethane and dried with anhydrous magnesium sulfate, the solution was concentrated to obtain a khaki solid, which was purified by silica gel column chromatography, and the mixed solvent of petroleum ether / dichloromethane (3 / 1, v / v) was used as the eluent to obtain a white solid with a yield of 75%.1 H NMR, 13 CNMR, MS and elemental analysis results show that the obtained compound is the target product, and the chemical reaction equation of the preparation process is as follows:

[0089]

[009...

Embodiment 1

[0121] The preparation of embodiment 1 compound Z1

[0122] Under argon atmosphere, in a 100mL three-necked flask, add compound M4-1 (2.94g, 2.4mol), bis(9,9-dimethyl-9H-fluoren-2-yl)amine (2.02g, 5.0mmol ), sodium tert-butylate (1.84g, 19.2mmol), palladium acetate (27mg, 0.12mmol) and 50ml of toluene. Heat and stir to 85°C, add 0.12ml of tri-tert-butylphosphine in toluene (0.24mmol, 2mol / L), and react for 12h. After stopping the reaction, the solvent was concentrated, and the crude product was purified by column chromatography using a mixed solvent of petroleum ether and dichloromethane (2 / 1, v / v) as the eluent to obtain a green solid. 1 H NMR, 13 CNMR, MS and elemental analysis results show that the obtained compound is the target product, and the chemical reaction equation of the preparation process is as follows:

[0123]

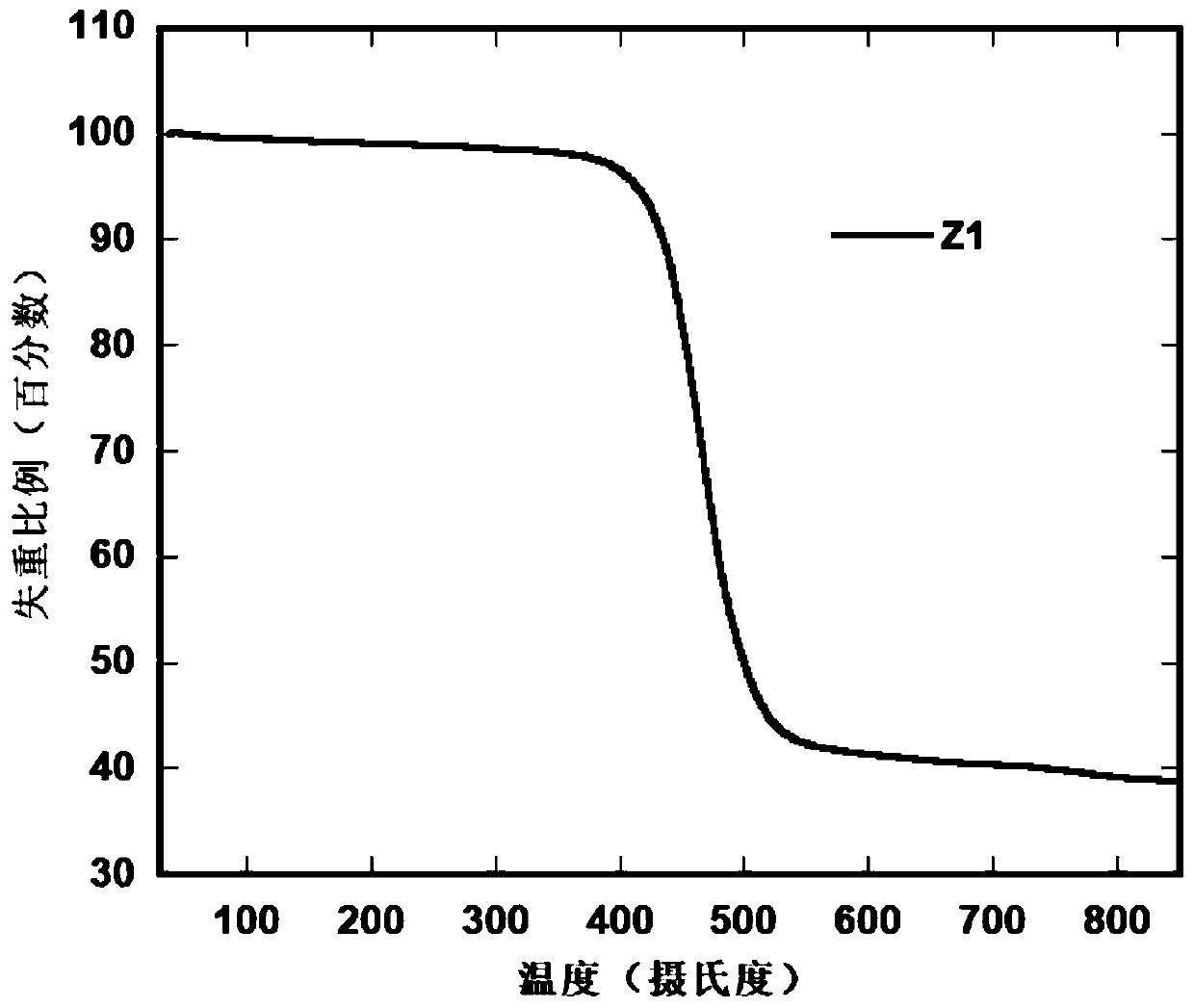

[0124] The thermogravimetric analysis (TGA) curve of compound Z1 is as follows figure 1shown. It can be seen from the figure that when the heat...

Embodiment 2

[0125] Embodiment 2: the synthesis of compound Z2

[0126] Under argon atmosphere, in a 100mL three-necked flask, add compound M4-1 (2.94g, 2.4mol), N-[1,1-biphenyl]-4-yl-9,9-dimethyl-9H- Fluorene-3-amine (1.81 g, 5.0 mmol), sodium tert-butylate (1.84 g, 19.2 mmol), palladium acetate (27 mg, 0.12 mmol) and 50 ml of toluene. Heat and stir to 85°C, add 0.12ml of tri-tert-butylphosphine in toluene (0.24mmol, 2mol / L), and react for 12h. After stopping the reaction, the solvent was concentrated, and the crude product was purified by column chromatography, using a mixed solvent of petroleum ether and dichloromethane (3 / 1, v / v) as the eluent, and finally a green solid was obtained. 1 H NMR, 13 CNMR, MS and elemental analysis results show that the obtained compound is the target product, and the chemical reaction equation of the preparation process is as follows:

[0127]

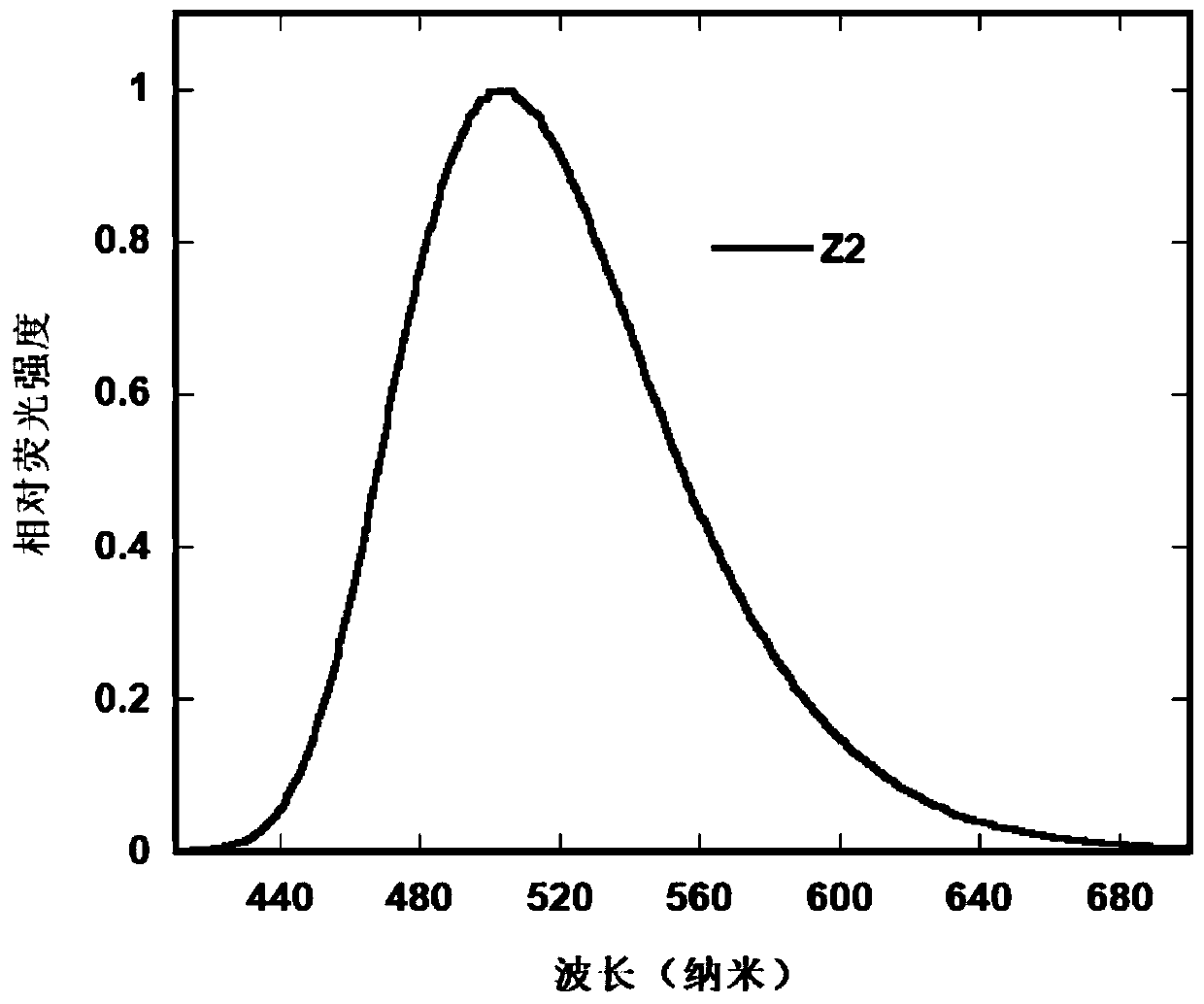

[0128] The fluorescence emission spectrum of compound Z2 in the thin film state is as follows figure 2 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| solubility (mass) | aaaaa | aaaaa |

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com