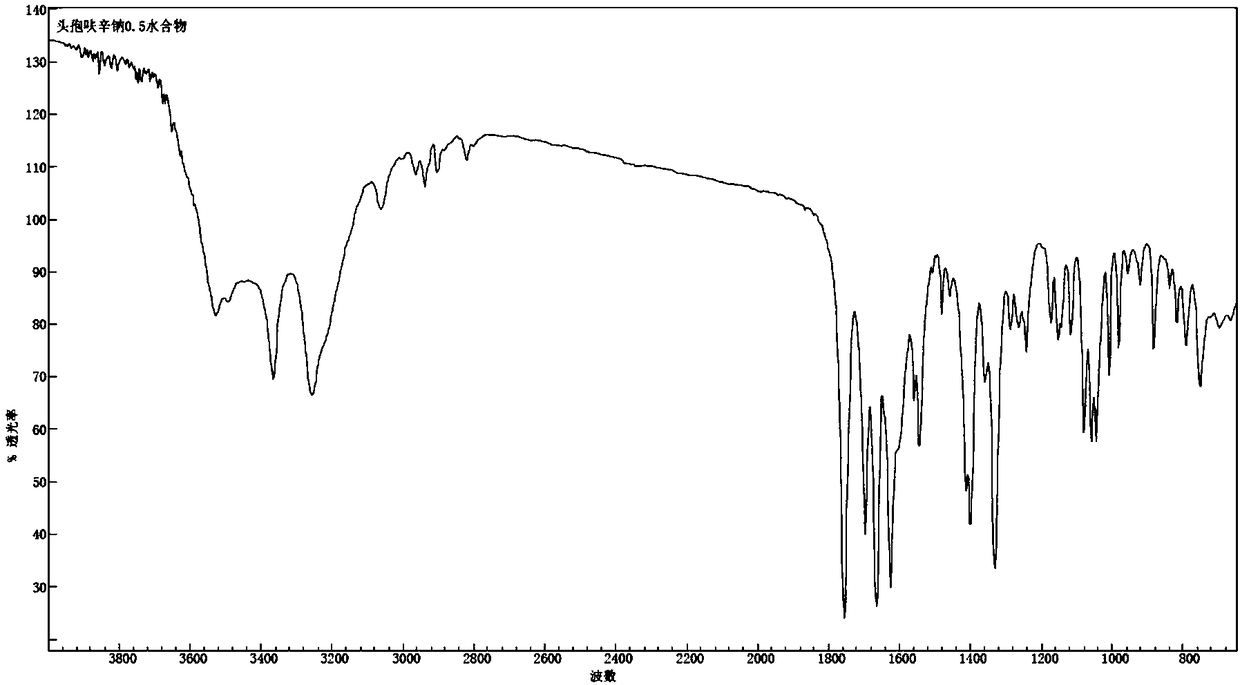

Cefuroxime sodium compound containing 1/2 of water

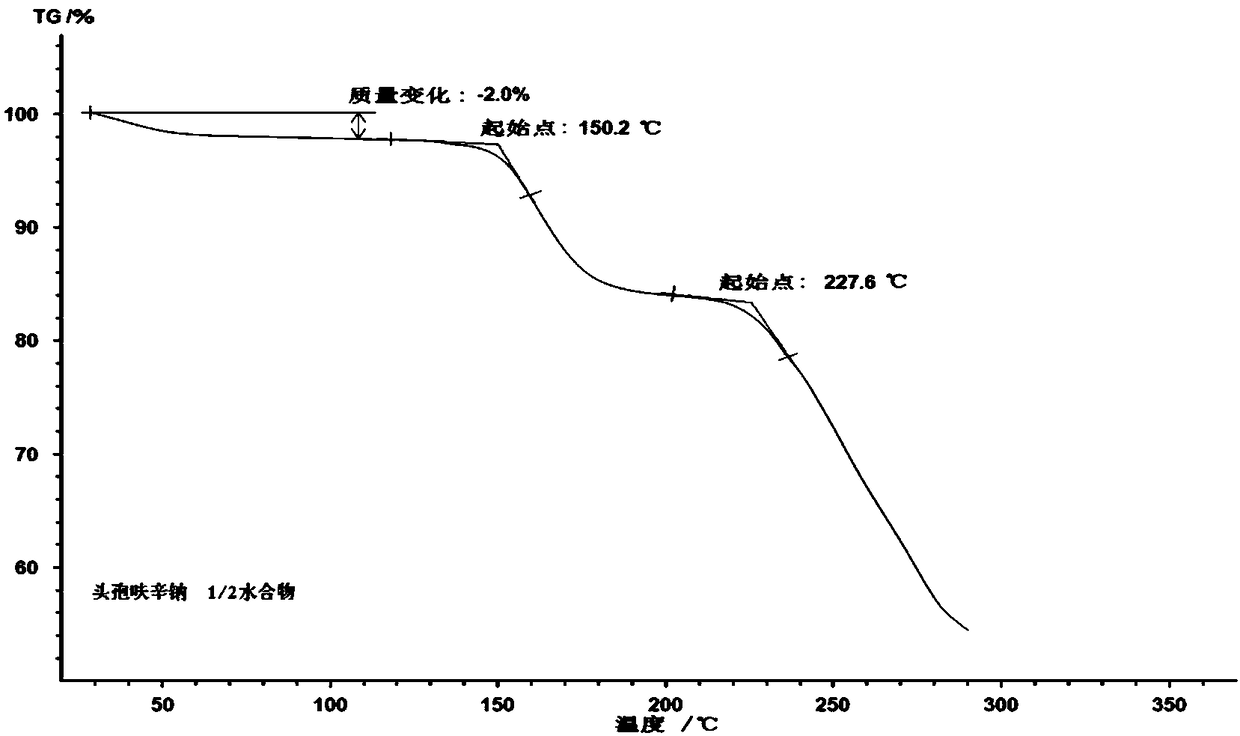

A technology of cefuroxime sodium and furoxin sodium, which is applied in organic chemistry, antibacterial drugs, organic active ingredients, etc., can solve the problems of low thermal decomposition temperature, poor fluidity, and unclearness, and achieve wide application prospects and thermal stability Good performance and fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 1 / 2 cefuroxime sodium compound

[0033] (1) At room temperature, 848.8 g of cefuroxime acid and 272.2 g of sodium acetate were added to a mixed solution of water (2 L) and ethanol (2 L), stirred at 150 rpm, and reacted for 2 hours to obtain cefuroxime sodium solution;

[0034] (2) Add 10 g of seed crystals to the above cefuroxime sodium solution, lower the temperature to -5°C, slowly add ethanol, stir and crystallize at 150 rpm, and filter;

[0035] (3) Dissolve the above filtrate in 2L of water, add 1g of activated carbon, stir and adsorb for 30min, filter, slowly add 3L of ethanol to the filtrate, lower the temperature to -5°C, stir and crystallize at 150rpm for 1h, filter; wash the filtrate with ethanol, Vacuum drying at 40°C for 1 hour yielded 846.3 g of the 1 / 2 water cefuroxime sodium compound.

[0036] Test results:

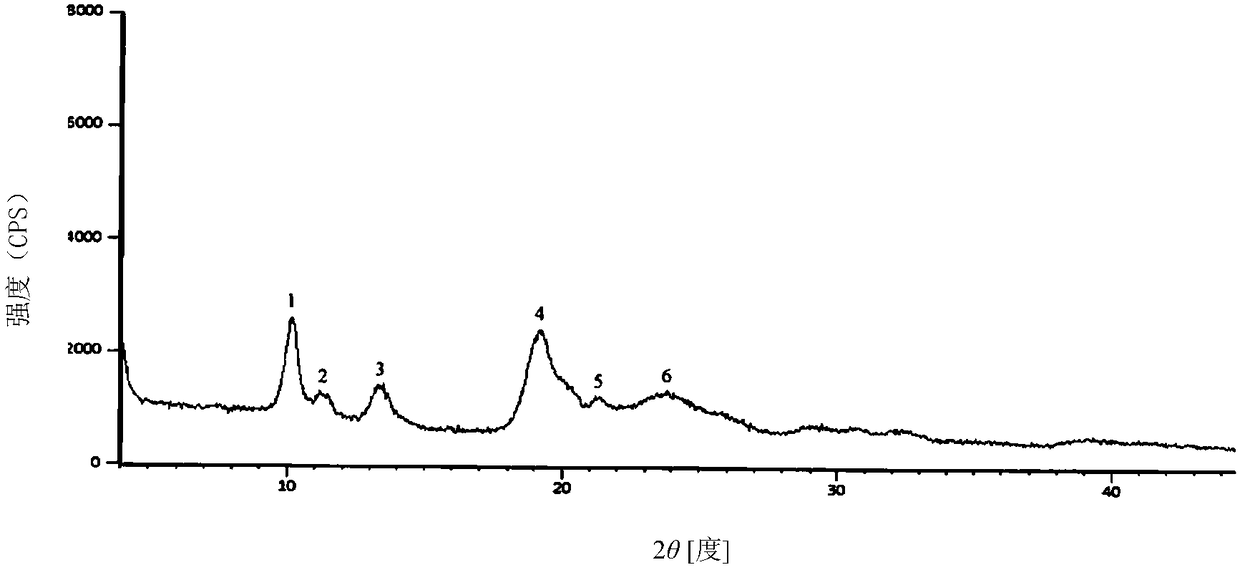

[0037] The X-ray powder diffraction pattern has characteristic diffraction peaks at the diffraction angle 2θ of 10...

Embodiment 2

[0040] The preparation of embodiment 2 1 / 2 cefuroxime sodium compound

[0041] (1) At room temperature, 849.6 g of cefuroxime acid and 274.1 g of sodium acetate were added to a mixed solution of water (2 L) and methanol (2.5 L), stirred at 500 rpm, and reacted for 2 hours to obtain cefuroxime sodium solution;

[0042] (2) Add 10 g of seed crystals to the above-mentioned cefuroxime sodium solution, lower the temperature to 0° C., slowly add 2 L of methanol, stir and crystallize at 500 rpm, and filter;

[0043] (3) Dissolve the above filtrate in 3L of water, add 1.5g of activated carbon, stir and adsorb for 30min, filter, slowly add 3L of methanol to the filtrate, lower the temperature to 0°C, stir and crystallize at 500rpm for 1h, filter; wash the filtrate with methanol, Vacuum drying at 40°C for 1 hour gave 851.1 g of the 1 / 2 water cefuroxime sodium compound.

[0044] Test results:

[0045] The X-ray powder diffraction pattern has characteristic peaks at diffraction angles 2...

Embodiment 3

[0048] Example 3 Preparation of 1 / 2 cefuroxime sodium compound

[0049] (1) At room temperature, add 906.2 g of cefuroxime acid and 285.3 g of sodium acetate into a mixed solution of water (2 L) and ethyl acetate (2 L), stir at 300 rpm, and react for 1 hour to obtain cefuroxime sodium solution;

[0050] (2) Add 10 g of seed crystals to the above-mentioned cefuroxime sodium solution, lower the temperature to -1 ° C, slowly add 2 L of ethyl acetate, stir and crystallize at 300 rpm, and filter;

[0051] (3) Dissolve the above filtrate in 2L of water, add 2g of activated carbon, stir and absorb for 30min, filter, slowly add 3L of ethyl acetate to the filtrate, lower the temperature to -1°C, stir and crystallize at 300rpm for 1h, and filter; The filtrate was washed and vacuum-dried at 40° C. for 1 hour to obtain 877.5 g of 1 / 2 cefuroxime sodium compound.

[0052] Test results:

[0053] The X-ray powder diffraction pattern has characteristic peaks at the diffraction angle 2θ of 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com