Polyether ketone ketone-based composite, composition, restoration, preparation method and application thereof

A polyetherketone ketone-based, composite material technology, applied in the field of medical biomaterials, can solve the problems of poor antibacterial performance and low biological activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

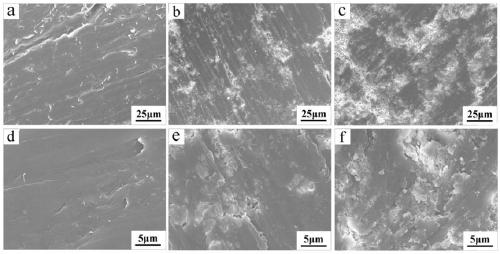

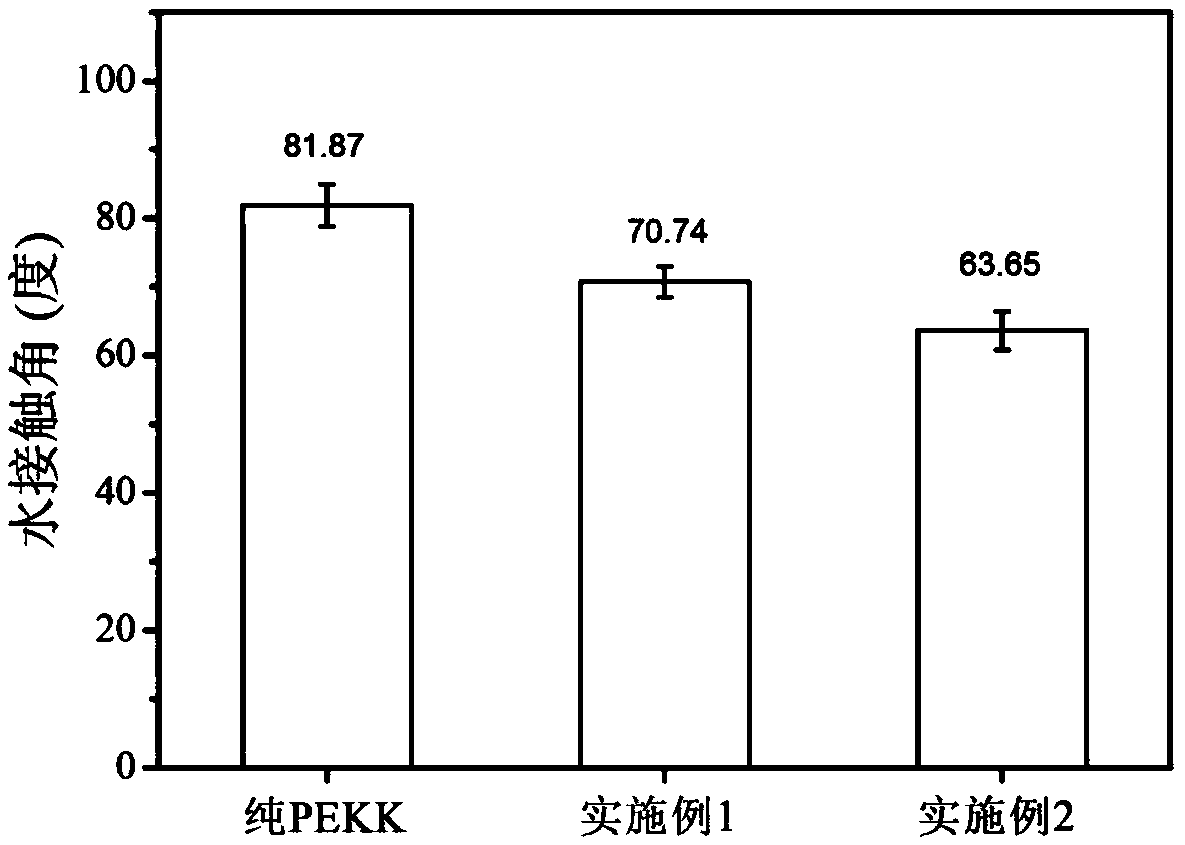

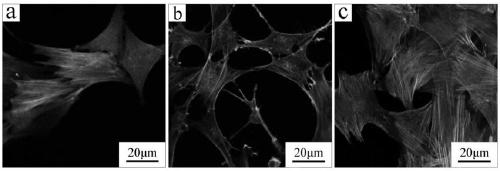

[0073] Mix 4.6kg D50 silicon nitride powder with a particle size of 2.5μm and 5.4kg D50 polyetherketone ketone powder with a particle size of 20μm uniformly to obtain a mixed powder; then pour the mixed powder into absolute ethanol, ultrasonically clean and disperse, and then Dry in an oven at 80°C, pour it into deionized water, ultrasonically clean and disperse, and then place it in an oven at 80°C for drying to obtain a polyetherketone ketone-based raw material composition; The polyetherketone ketone-based composite material is obtained by hot pressing and sintering in a heating mold; the hot pressing temperature is 356° C.; the pressure is 3 MPa; and the hot pressing holding time is 40 minutes.

Embodiment 2

[0075]Mix 7.2kg D50 silicon nitride powder with a particle size of 2μm and 2.8kg D50 polyetherketone ketone powder with a particle size of 15μm uniformly to obtain a mixed powder; then the mixed powder is melted and blended with a twin-screw extruder at high temperature and extruded. After granulation, the master batch of polyetherketone ketone-based composite material was obtained, and the temperature of melt extrusion was 390° C.; the pressure of the twin-screw extruder was 90MPa. The polyetherketone ketone-based composite material masterbatch is injection-molded in an injection molding machine to obtain a polyetherketone-ketone-based composite material; the injection molding temperature is 390° C.; and the injection molding pressure is 110 MPa.

Embodiment 3

[0077] Mix 4.6g of D50 silicon nitride powder with a particle size of 3μm and 5.4g of polyetherketone ketone powder with a D50 particle size of 25μm; then pour the mixed powder into absolute ethanol, ultrasonically clean and disperse, and then place it at 80°C drying in an oven, pouring into deionized water, ultrasonically cleaning and dispersing, and then drying in an oven at 80°C to obtain a polyetherketone ketone-based raw material composition; cold-pressing and sintering the polyetherketone ketone-based raw material composition After molding, a polyetherketone ketone-based composite material is obtained; wherein, the heating rate of the sintering furnace is 2°C / min; the sintering temperature is 360°C; and the sintering holding time is 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com