A kind of p/n/si multi-element polyphosphosilazane flame retardant for epoxy resin and preparation method thereof

A multi-element technology for epoxy resin, applied in the field of P/N/Si multi-element polyphosphorus silazane flame retardant for epoxy resin and its preparation field, can solve the problem of poor mechanical properties, epoxy resin cured product The problem of low heat resistance, etc., achieves the effect of high-quality retention rate, easy to achieve large-scale production, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of P / N / Si Multi-element Polyphosphosilazane Flame Retardant

[0026] Under the protection of high-purity nitrogen, add DOPO and chloroform to the three-necked flask in turn, raise the temperature to 45°C, and after DOPO is completely dissolved, add the mixed solution of PVSZ and chloroform, and stir for a certain period of time. Then add the mixed solution of AIBN and chloroform through the constant pressure dropping funnel, continue to maintain the temperature at 45 ° C for 24 hours, after the reaction, filter with suction and collect the filtrate, the filtrate is washed, distilled, purified and other post-treatments, and vacuum-dried to obtain P / N / Si multi-element polyphosphosilazane flame retardant for epoxy resin. In this example, the molar ratio of PVSZ to DOPO is 1:1, the amount of AIBN is 0.2% of DOPO moles, and the structure of the obtained flame retardant is:

[0027]

[0028] The structural characterization data are:

[0029] FTIR: 3312cm -1 ...

Embodiment 2

[0033] Preparation of P / N / Si Multi-element Polyphosphosilazane Flame Retardant

[0034] Under the protection of high-purity nitrogen, add DOPO and toluene to the three-necked flask in turn, raise the temperature to 80°C, and after DOPO is completely dissolved, add the mixed solution of PVSZ and toluene, and stir for a certain period of time. Then add the mixed solution of AIBN and toluene through the constant pressure dropping funnel, continue to maintain the temperature at 80 ° C for 10 h, after the reaction, filter with suction and collect the filtrate, the filtrate is post-treated by washing, distillation, purification, etc., and vacuum-dried to obtain P / N / Si multi-element polyphosphosilazane flame retardant for epoxy resin. In this embodiment, the molar ratio of PVSZ to DOPO is 1:3, and the amount of AIBN is 0.5% of the molar number of DOPO.

[0035] The structural characterization data are:

[0036] FTIR: 3334cm -1 (N-H), 3036cm -1 (Ph-H), 2991cm -1 (CH 3 ), 2130cm ...

Embodiment 3

[0039] Application of P / N / Si Multi-element Polyphosphosilazane Flame Retardant in Epoxy Resin

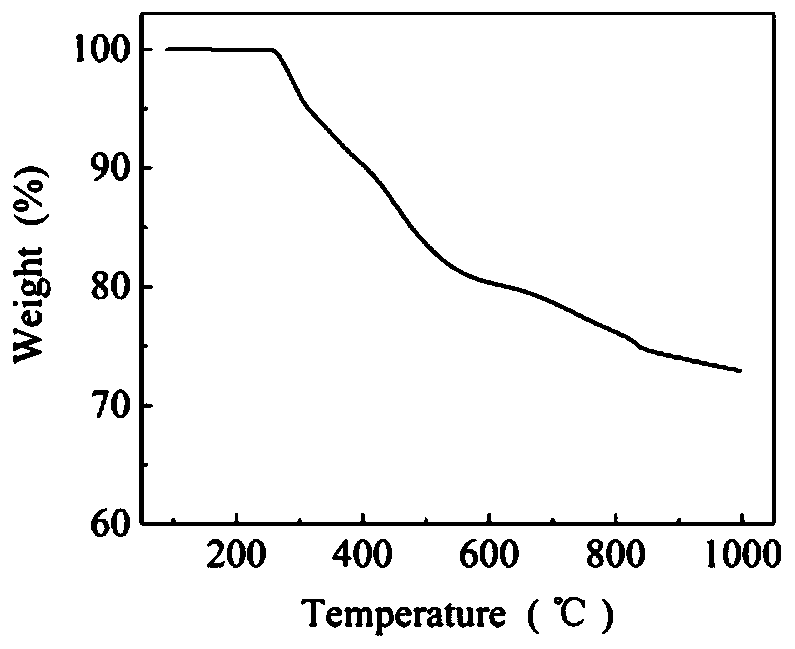

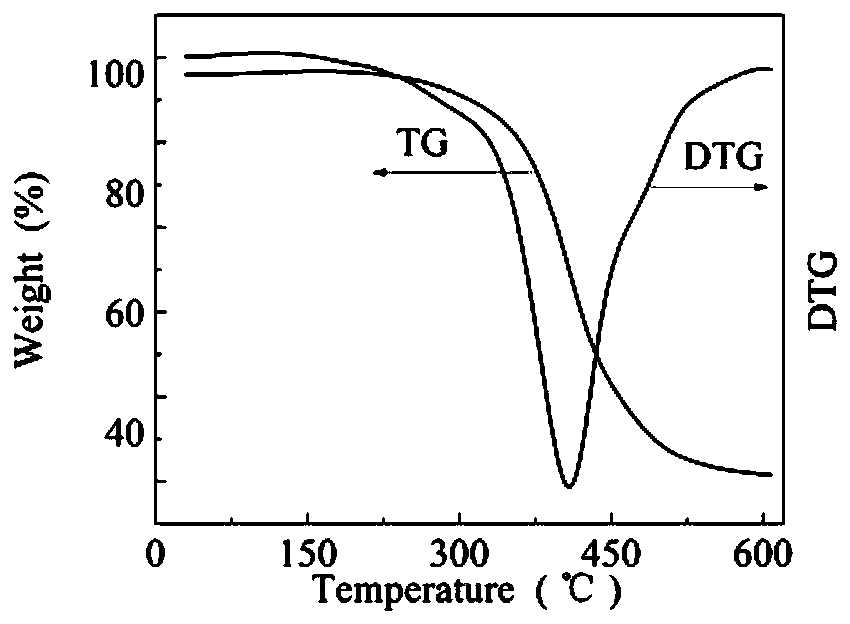

[0040] The limiting oxygen index of the 4,5-epoxycyclohexane-1,2-diglycidyl carboxylate epoxy resin modified with the product obtained in Example 1 (addition mass fraction is 10%) is 38.0%, UL- 94 vertical combustion can reach V-0 level, which has good flame retardant effect; after modification, the epoxy resin is stable at N 2 TGA in the atmosphere (heating rate is 10°C / min) (such as figure 2 ) The results show that: weight loss 5% (T d5 ) and 10% weight loss (T d10 ) corresponding temperatures are 320°C and 356°C respectively, and the temperature corresponding to the maximum thermogravimetric rate (T dmax ) is 407°C, the mass retention rate at 600°C is 33.2%, and has good thermal stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com