A kind of water-based coating with air purification function and preparation method thereof

A water-based coating and air purification technology, applied in coatings and other directions, can solve problems such as low hardness, wear resistance and other physical indicators, no indoor air purification, poor alcohol and alkali resistance, etc., to achieve low equipment dependence, The effect of small environmental impact and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

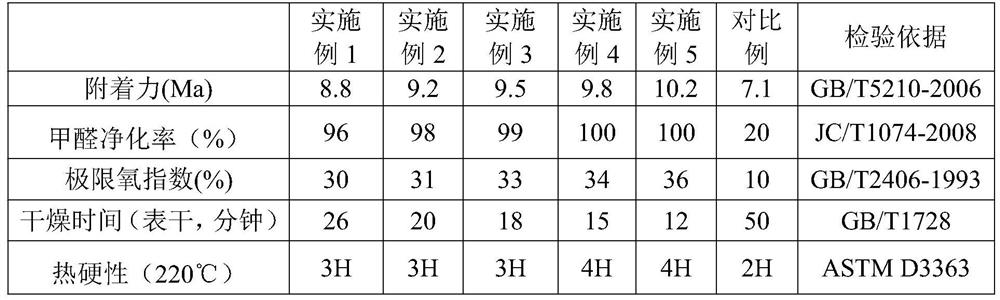

Examples

Embodiment 1

[0029] A water-based coating with air purification function, which is made of the following components in parts by weight: 55 parts of film-forming polymer, 5 parts of heterogeneously doped titanium dioxide, 10 parts of titanium dioxide, 1 part of perfluoroalkyl sulfonate, hexadecimal 1 part of sodium phosphate, 1 part of tributyl phosphate, 20 parts of water.

[0030] The preparation method of described film-forming polymer, comprises the steps:

[0031] Ⅰ Connect the mechanical stirring, thermometer, condenser tube, nitrogen device and the four-necked bottle tightly, confirm that the airtightness of the airtight device is intact, and then add 17.8 g of 4-potassium sulfonate-1,8-naphthalene anhydride, 2-(1H-benzimidazol-2-yl)-1,1-ethylene glycol 10g and p-toluenesulfonic acid 3g; heat the system for 1 hour to raise the temperature to 150°C, start stirring and keep it warm for 1 hour; heat up to 175°C Keep it for 1 hour, then raise the temperature to 195°C and keep it for 2 h...

Embodiment 2

[0036] A water-based coating with air purification function, which is made of the following components in parts by weight: 58 parts of film-forming polymer, 7 parts of heterogeneously doped titanium dioxide, 12 parts of titanium dioxide, 2 parts of alkyl aryl polyether, polycarboxylic acid 2 parts of sodium salt, 31002 parts of defoamer Deqian, 22 parts of water.

[0037] The preparation method of described film-forming polymer, comprises the steps:

[0038] Ⅰ Connect the mechanical stirring, thermometer, condenser tube, helium device and the four-necked bottle tightly, confirm that the airtightness of the airtight device is intact, and then add 17.8g of 4-potassium sulfonate-1,8-naphthalene anhydride in sequence , 2-(1H-benzimidazol-2-yl)-1,1-ethylene glycol 10g and tetraisopropyl titanate 4g; heat the system for 1.2 hours to raise the temperature to 152°C, start stirring and keep warm for 1.2 hours; heat up Keep at 177°C for 1.2 hours, then raise the temperature to 198°C fo...

Embodiment 3

[0043] A water-based paint with air purification function, which is made of the following components in parts by weight: 60 parts of film-forming polymer, 7 parts of heterogeneously doped titanium dioxide, 13 parts of titanium dioxide, 3 parts of sodium octyl succinate sulfonate, hexametaphosphoric acid 2 parts of sodium, 3 parts of defoamer BYK0883, 27 parts of water.

[0044] The preparation method of described film-forming polymer, comprises the steps:

[0045] Ⅰ Connect the mechanical stirring, thermometer, condenser tube, neon gas device and the four-necked bottle tightly, confirm that the airtightness of the airtight device is intact, and then add 17.8g of 4-potassium sulfonate-1,8-naphthalene anhydride in sequence , 2-(1H-benzimidazol-2-yl)-1,1-ethanediol 10g and zinc acetate 4.5g; heat the system for 1.5 hours to raise the temperature to 156°C, start stirring and keep warm for 1.5 hours; heat up to 177°C Keep it for 1.3 hours, then raise the temperature to 200°C and k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com