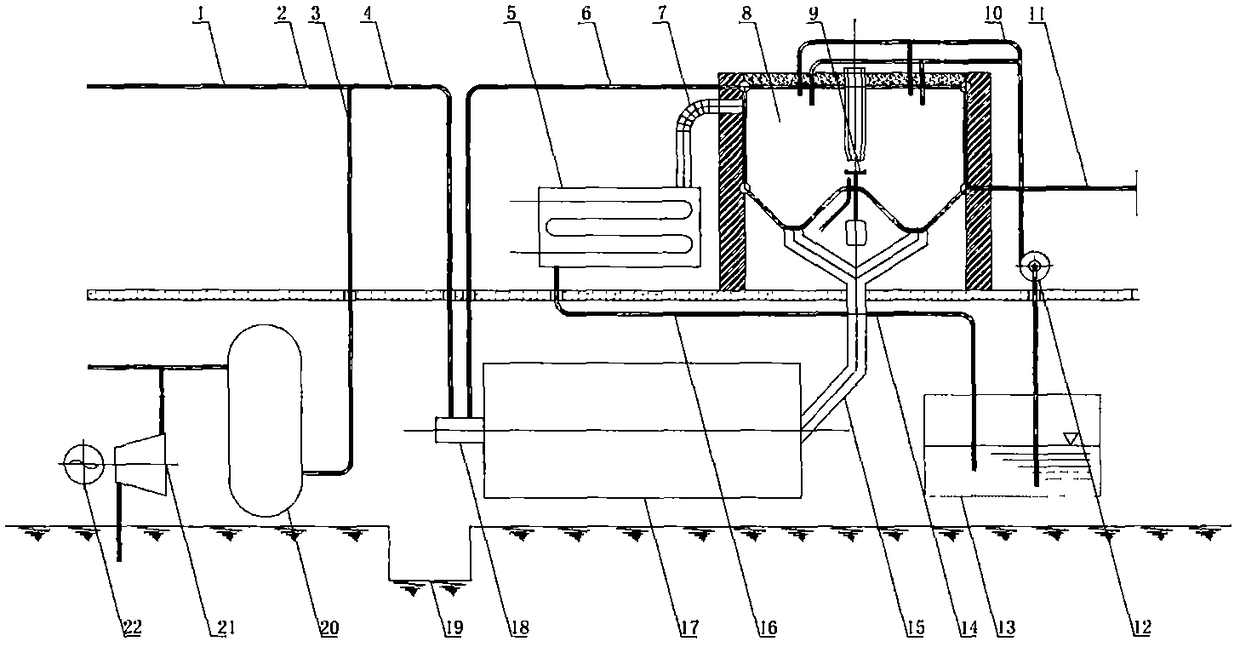

Molten-state high-temperature matter physical sensible heat recovery system

A technology of sensible heat recovery and molten state, which is applied in the direction of recycling technology, waste heat treatment, heat exchanger type, etc., can solve the problems of low cooling rate, sacrifice of steel slag cement quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

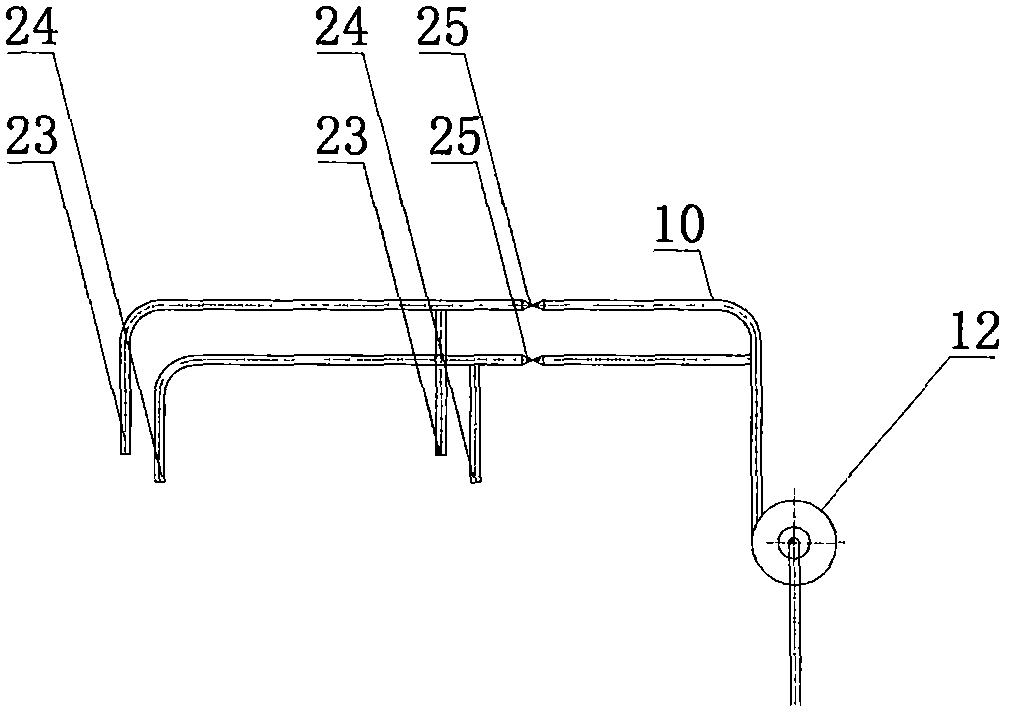

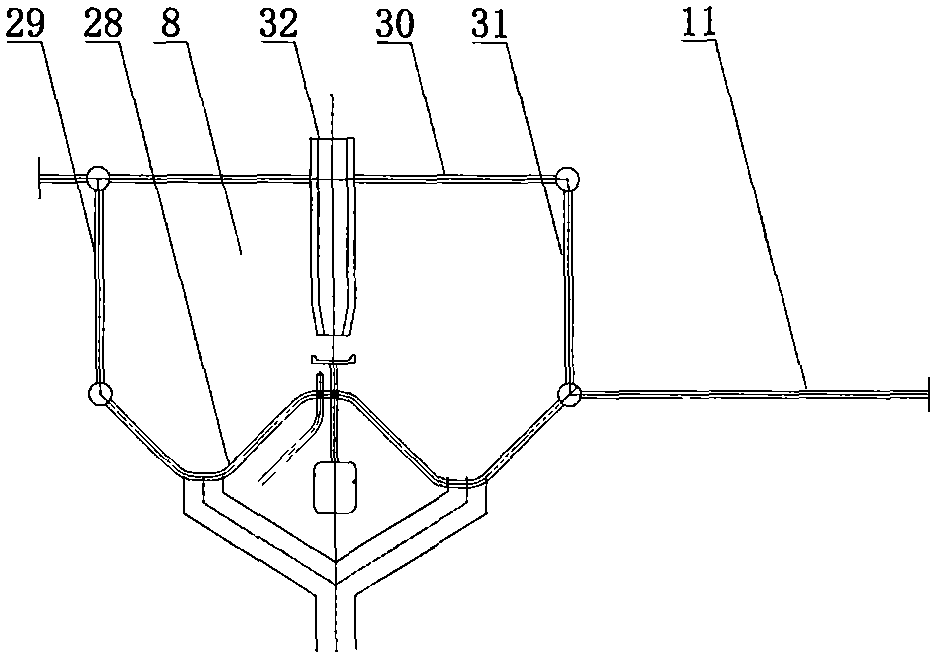

Examples

Embodiment

[0028] The flow rate of metallurgical slag is 2×2.3t / min=2×138t / h, and the bulk specific gravity of metallurgical slag is 1.250t / m3, then the volume flow rate of metallurgical slag is 2×138 / 1.25=2×110.4m3 / h. Since metallurgical slag is operated intermittently, the actual flow rate of metallurgical slag in the granulation system is taken as 110.4m3 / h. Metallurgical slag temperature 1550 ℃. According to thermodynamic calculations, steel slag completes the phase transformation of steel slag before 1200°C, that is, transforms from a molten state to a solid glass phase, and at this time it consumes 17% of the heat of phase change equivalent to the heat of steel slag. That is, the heat between 1550°C and 1100°C is consumed in the phase transformation of steel slag and water in the low temperature space.

[0029] The amount of atomized water sprayed is 16-20t / h.

[0030] The cooling water is 50°C industrial return water with a flow rate of 50t / h to produce 2.0MPa 120°C high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com