Method for detecting concentration of active components in Grignard reagent solution

A technology of Grignard reagent and active ingredient, which is applied in the field of detection of active ingredient concentration in Grignard reagent solution, can solve the problem that the concentration of active ingredient is not easy to be accurately detected, and can solve the problem that the concentration of active substance cannot be effectively detected, improve the promotion potential and Application prospect, effect of wide range of substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

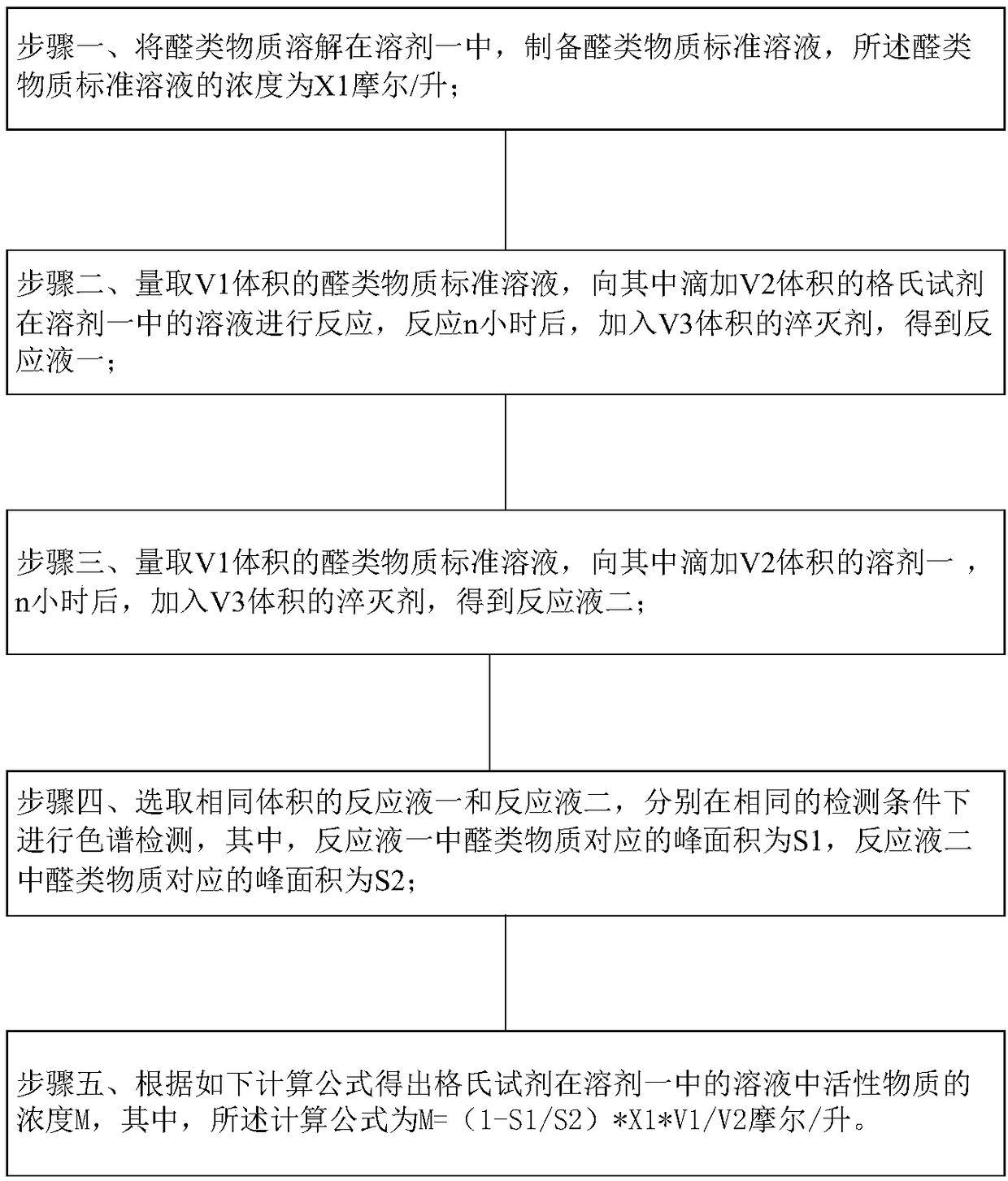

Method used

Image

Examples

example 1

[0040] Example 1 The detection method of the concentration of active ingredients in THF solution of ethylmagnesium bromide

[0041] Using iodine as an initiator, bromoethane (218g, 2mol) in tetrahydrofuran (500mL) was added dropwise to tetrahydrofuran (500mL) containing magnesium chips (57.6g, 2.4mol), and the reaction prepared tetrahydrofuran of ethylmagnesium bromide solution. Among them, the concentration of active ingredients in the product is roughly estimated to be below 2.0 mol / liter.

[0042] Step 1, prepare benzaldehyde standard solution, dissolve the benzaldehyde purified by distillation in dry THF, and obtain the concentration of benzaldehyde THF solution as 1.0 mol / liter;

[0043] Step 2, under a nitrogen atmosphere, measure 10 mL of the above-mentioned 1 mol / L benzaldehyde tetrahydrofuran solution, add dropwise 4 mL of the prepared ethylmagnesium bromide tetrahydrofuran solution; after reacting for 6 hours, add 10 mL of water as a quenching agent, to obtain reac...

example 2

[0050] The detection method of the active ingredient concentration of the ether solution of example 2 phenylmagnesium iodide

[0051] The ether solution (700mL) of iodobenzene (204g, 1mol) was added dropwise to ether (300mL) containing magnesium chips (28.8g, 1.2mol) to prepare the ether solution of phenylmagnesium iodide. The concentration of active ingredients in the product is roughly estimated to be below 1 mole / liter.

[0052] Step 1, preparing 4-methoxybenzaldehyde standard solution, dissolving the purified 4-methoxybenzaldehyde in distilled ether in dry ether to obtain a concentration of 4-methoxybenzaldehyde solution of 1.0 mol / liter;

[0053] Step 2, measure the ether solution of the above-mentioned 1 mol / liter 4-methoxybenzaldehyde of 10mL, dropwise add the ether solution of phenylmagnesium iodide prepared by 8mL therein; after reacting for 6 hours, add 10mL of methanol as a quenching Killing agent, obtain reaction solution 1;

[0054] Step 3, measure 10 mL of the ...

example 3

[0060] Example 3 Detection method of active ingredient concentration in tetrahydrofuran solution of ethynylmagnesium bromide

[0061] Add acetylene gas to the newly prepared 0.6M butylmagnesium bromide tetrahydrofuran solution to prepare a tetrahydrofuran solution of ethynylmagnesium bromide. The concentration of active ingredients in the product is roughly estimated to be below 0.6 mol / liter.

[0062] Step 1, preparation of benzaldehyde standard solution, the benzaldehyde purified by distillation is dissolved in dry tetrahydrofuran to obtain a concentration of benzaldehyde solution of 1.0 mol / liter;

[0063] Step 2, under a nitrogen atmosphere, measure 10 mL of the above-mentioned 1 mol / L benzaldehyde tetrahydrofuran solution, add dropwise 8 mL of the prepared ethynylmagnesium bromide tetrahydrofuran solution; after reacting for 6 hours, add 10 mL of water as a quenching agent, to obtain reaction solution 1;

[0064] Step 3, under a nitrogen atmosphere, measure 10 mL of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com