Ultralow-friction solid-liquid composite lubricating coating and preparation method thereof

A solid-liquid composite and lubricating coating technology, which is applied in coatings, lubricating compositions, metal material coating processes, etc., can solve the limitations of the wide application and industrialization of DLC solid lubricating materials, the lubricating effect is not as good as fluid lubrication, residual High stress and other problems, to achieve the effect of industrial application, best comprehensive performance, simple operation and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing a composite solid-liquid lubricating coating, the coating method for preparing a diamond-like solid phase comprising the steps of:

[0037] (1) providing a substrate, an ion source, Ar gas as the working gas source, etching of the substrate cleaning;

[0038] (2) after the modification magnetron sputtering process complex hydride, hydrogenated diamond-like surface prepared solid phase.

[0039] In step (1), the etching of the base object of an aspect that the cleaned to remove surface impurities, on the other hand that the surface of the substrate is increased, to increase the adhesion between the solid phase and the diamond-like matrix. The process specifically includes: an Ar gas plasma etching cleaning substrate, wherein the ion source operating current of 0.2A, the operating power of 200 ~ 350W, a negative bias to the substrate 100V.

[0040] In step (2), using the magnetron sputtering composite processing metho...

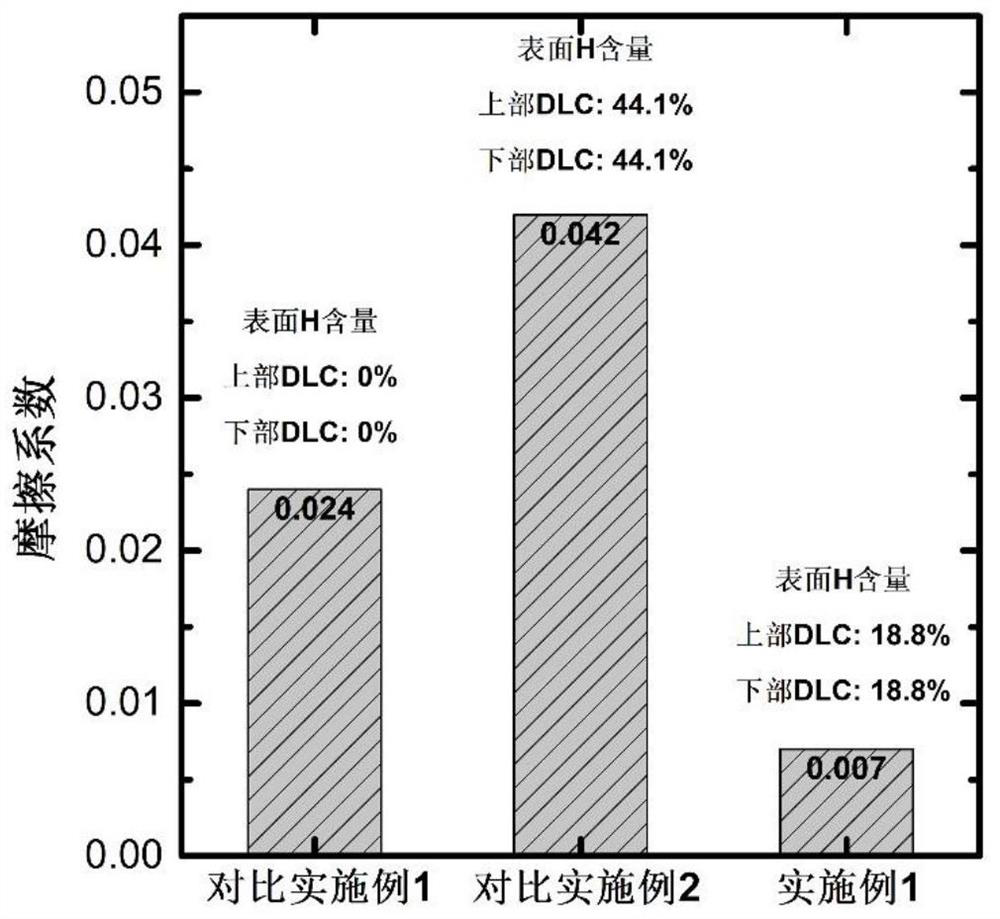

Embodiment 1

[0045] (1) After the ultrasonic cleaning the substrate was placed on a vacuum chamber the workpiece carrier;

[0046] (2) The vacuum chamber pressure was adjusted to be 2.7 × 10 -3 PA, open linear ion source, the ion source into the linear 40sccm argon, linear ion source operating current of 0.2A, operating power is 280W, while the substrate is set to a negative bias 100V, etching of the substrate cleaning 15min;

[0047] (3) deposition of diamond on a surface of a solid phase matrix

[0048] Open source magnetron sputtering, pre-made diamond-like solid phase without hydrogen: magnetron sputtering source is high-purity graphite target (purity of ≧ 99.99%), the magnetron sputter source into argon gas flow rate of 50 sccm, magnetron sputtering target power 1350W, operating current of 2.8A, while a negative bias to the substrate 50V, the working pressure is maintained at 0.46 Pa, the deposition time was 1 hour. Then, turn off the magnetron sputtering source, the ion source is turned ...

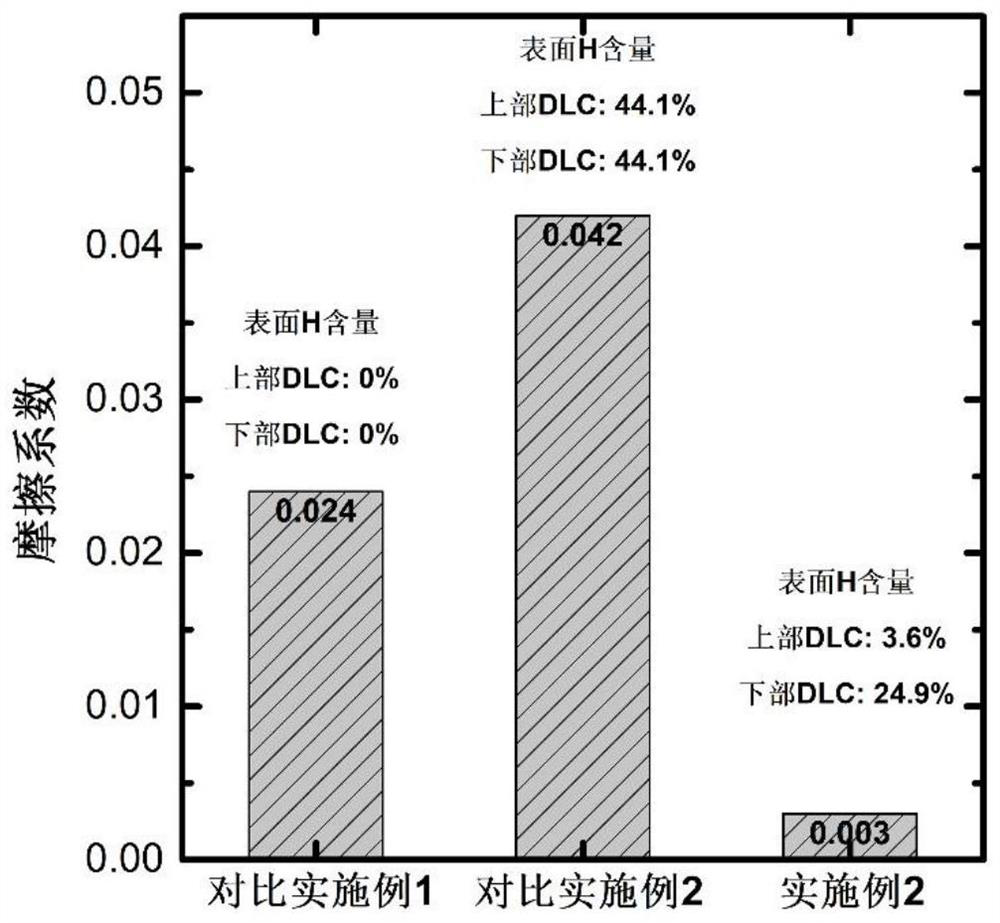

Embodiment 2

[0053] (1) After the ultrasonic cleaning the substrate was placed on a vacuum chamber the workpiece carrier;

[0054] (2) The vacuum chamber pressure was adjusted to be 2.7 × 10 -3 PA, open linear ion source, the ion source into the linear 40sccm argon, linear ion source operating current of 0.2A, operating power is 280W, while the substrate is set to a negative bias 100V, etching of the substrate cleaning 15min;

[0055] (3) deposition of diamond on a surface of a solid phase matrix

[0056] Open source magnetron sputtering, pre-made diamond-like solid phase without hydrogen: magnetron sputtering source is high-purity graphite target (purity of ≧ 99.99%), the magnetron sputter source into argon gas flow rate of 50 sccm, magnetron sputtering target power 1350W, operating current of 2.8A, while a negative bias to the substrate 50V, the working pressure is maintained at 0.46 Pa, the deposition time was 1 hour. Then, turn off the magnetron sputtering source, the ion source is turned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com