A method for methane production and high-efficiency deep denitrification of urban sewage

A technology for deep denitrification and methane production, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high energy consumption, high operating cost and denitrification efficiency Low-level problems, to achieve the effect of low sludge production, shortened reaction time, and high biomass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

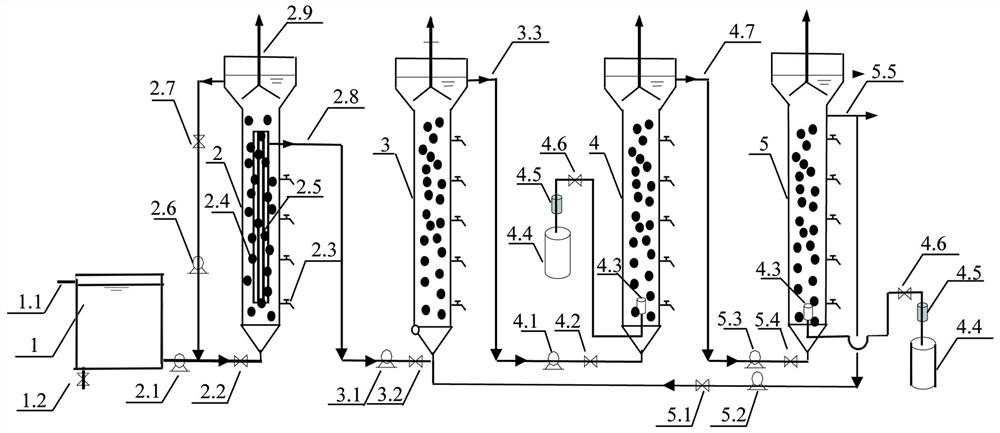

[0024]The present invention will be further described below with reference to the accompanying drawings and examples:figure 1As shown, 1 is the raw water tank; 2 is a meta-alkane membrane bioreactor; 3 is a short-range denitrification coupling anorexic ammonia oxidation reactor; 4 is a short-range nitrogenic anaerobic ammonia oxidation reactor; 5 is a nitrification reactor; 1.1 is the original water Water tank overflow tube; 1.2 is a raw water tank radial; 2.2 is a bioreactor inlet pump; 2.2 is a bioreactor inlet valve; 2.3 is a sampling port; 2.4 is particulate sludge; 2.5 is hollow The fiber membrane; 2.6 is a circulating liquid pump; 2.7 is a circulating liquid control valve; 2.8 is a bioreactor of the methane membrane; 2.9 is a three-phase separator exhaust port; 3.1 is a short-range denitrification coupled anorexic oxidation reactor Water pump; 3.2 is a short-range denitrification coupled anorexic ammonia oxidation reactor water supply valve; 3.3 is a short-range denitrificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com