Full-biocontrollable degradation multifunctional agricultural weeding and soil moisture-preserving mulching film

A multi-functional, all-biological technology, applied in plant protection, plant protection cover, application, etc., can solve the problems of unreachable degradation, poor film-forming ductility, and reduced material strength, and achieve cost saving, strong adhesion, and strong The effect of flexibility and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

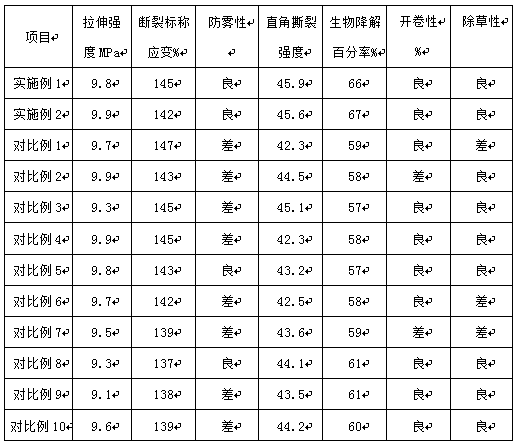

Examples

Embodiment 1

[0026] A fully biodegradable and multifunctional agricultural weeding and moisture-retaining mulch film is prepared from the following raw materials in parts by weight: 38 parts of dandelion extract, 8 parts of defatted soybean meal, 2.1 parts of modified polyamide-amine, 23 parts of modified starch, 2.9 parts of slightly cross-linked polyvinylpyrrolidone, 8 parts of corn gluten, 4.5 parts of carboxymethyl cellulose, 19.9 parts of modified polyacrylic acid copolymer, 5.1 parts of sodium alginate, 1.6 parts of carob gum, polyoxyethylene / polyoxypropylene 15 parts of copolymer, 6.5 parts of modified sodium polyacrylate, 0.3 part of acetophenone, 0.1 part of sodium tripolyphosphate, 0.2 part of sodium hexametaphosphate, and 0.1 part of succinic anhydride.

[0027] Further, the micro-crosslinked polyvinylpyrrolidone is obtained by crosslinking polymerization of vinylpyrrolidone monomer and other crosslinkable monomers, and the crosslinkable monomer is one of EDMA, DAP, TAC, TAIC, TM...

Embodiment 2

[0035] A fully biodegradable and multifunctional agricultural weeding and moisture-retaining mulch film is prepared from the following raw materials in parts by weight: 38 parts of dandelion extract, 11 parts of defatted soybean meal, 2.7 parts of modified polyamide-amine, 28 parts of modified starch, 4.6 parts of slightly cross-linked polyvinylpyrrolidone, 10 parts of corn gluten, 3.9 parts of carboxymethyl cellulose, 24 parts of modified polyacrylic acid copolymer, 6 parts of sodium alginate, 3 parts of carob gum, polyoxyethylene / polyoxypropylene 19 parts of copolymer, 5.6 parts of modified sodium polyacrylate, 0.3 part of acetophenone, 0.1 part of sodium tripolyphosphate, 0.2 part of sodium hexametaphosphate, and 0.1 part of succinic anhydride.

[0036] Other preparation steps, raw material source are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com