Graphene oxide modified ammonia ester waterproof coating and preparation method thereof

A waterproof coating, graphene technology, applied in the field of coatings, to achieve the effects of improving mechanical properties, strong chemical bonding, and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

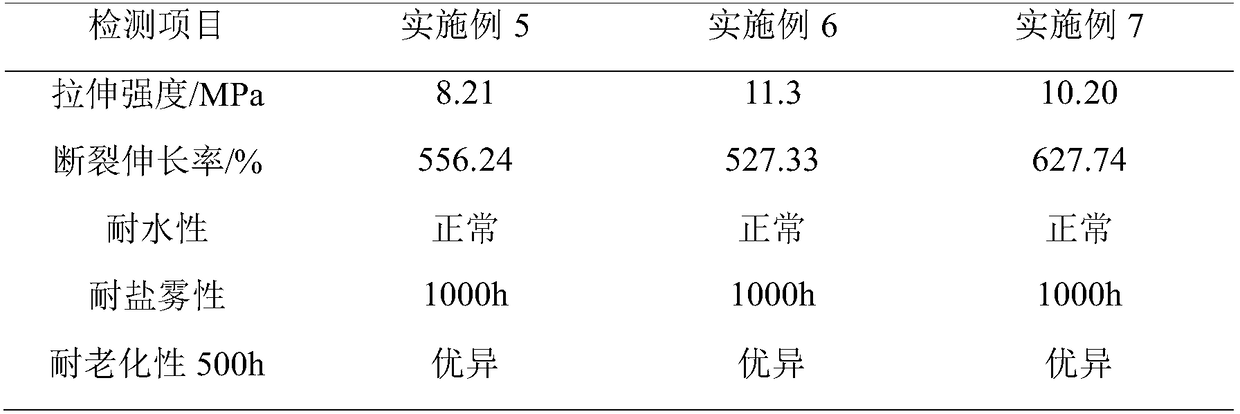

Examples

Embodiment 1

[0031] A graphene oxide modified urethane waterproof coating comprises a first component and a second component. The parts by weight of the first component include 0-40 parts of toluene diisocyanate, 0-50 parts of isophorone diisocyanate, 100-112 parts of polyether diol, 1-2 parts of graphene oxide; the second component Parts by weight include 70-80 parts of polyether triol, 30-40 parts of 3-chloro-2,6-diethylaniline, 10-15 parts of talcum powder, 10-15 parts of castor oil, 1-2 parts of diethylaniline Dibutyltin laurate or stannous octoate, 10-15 parts of dioctyl phthalate, 1-2 parts of defoamer. Wherein, the polyether diol hydroxyl value of the first component is 56mgKOH / g; the polyether trihydric alcohol hydroxyl value of the second component is 56mgKOH / g; the talcum powder of the second component has a mesh number of 800 The purpose is ultrafine talcum powder; the graphene oxide of the first component is graphene oxide prepared by Hummers method. The various raw materials...

Embodiment 2

[0033] A graphene oxide modified urethane waterproof coating comprises a first component and a second component. The parts by weight of the first component include 40 parts of toluene diisocyanate, 100 parts of polyether glycol, and 2 parts of graphene oxide; the parts by weight of the second component include 70 parts of polyether trihydric alcohol, 30 parts of 3-chloro -2,6-Diethylaniline, 15 parts of talc, 10 parts of castor oil, 1 part of dibutyltin dilaurate, 10 parts of dioctyl phthalate, 2 parts of defoamer. Wherein, the polyether diol hydroxyl value of the first component is 56mgKOH / g; the polyether trihydric alcohol hydroxyl value of the second component is 56mgKOH / g; the talcum powder of the second component has a mesh number of 800 The purpose is ultrafine talcum powder; the graphene oxide of the first component is graphene oxide prepared by Hummers method. The various raw materials involved in the present invention are commercially available common raw materials f...

Embodiment 3

[0035] A graphene oxide modified urethane waterproof coating comprises a first component and a second component. The parts by weight of the first component include 50 parts of isophorone diisocyanate, 112 parts of polyether diol, and 1 part of graphene oxide; the parts by weight of the second component include 80 parts of polyether triol, 40 parts of 3-Chloro-2,6-diethylaniline, 10 parts talc, 15 parts castor oil, 2 parts stannous octoate, 15 parts dioctyl phthalate, 1 part defoamer. Wherein, the polyether diol hydroxyl value of the first component is 56mgKOH / g; the polyether trihydric alcohol hydroxyl value of the second component is 56mgKOH / g; the talcum powder of the second component has a mesh number of 800 The purpose is ultrafine talcum powder; the graphene oxide of the first component is graphene oxide prepared by Hummers method. The various raw materials involved in the present invention are commercially available common raw materials for the preparation of polyuretha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com