A kind of single-layer graphene macromolecule composite epoxy resin adhesive and preparation method thereof

A technology of single-layer graphene and epoxy resin glue, which is applied in the direction of epoxy resin glue, non-polymer adhesive additives, adhesives, etc., can solve unfavorable practical applications, cannot fully exert the excellent performance of single-layer graphene, Process complexity and other issues, to achieve the effect of enhancing the bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

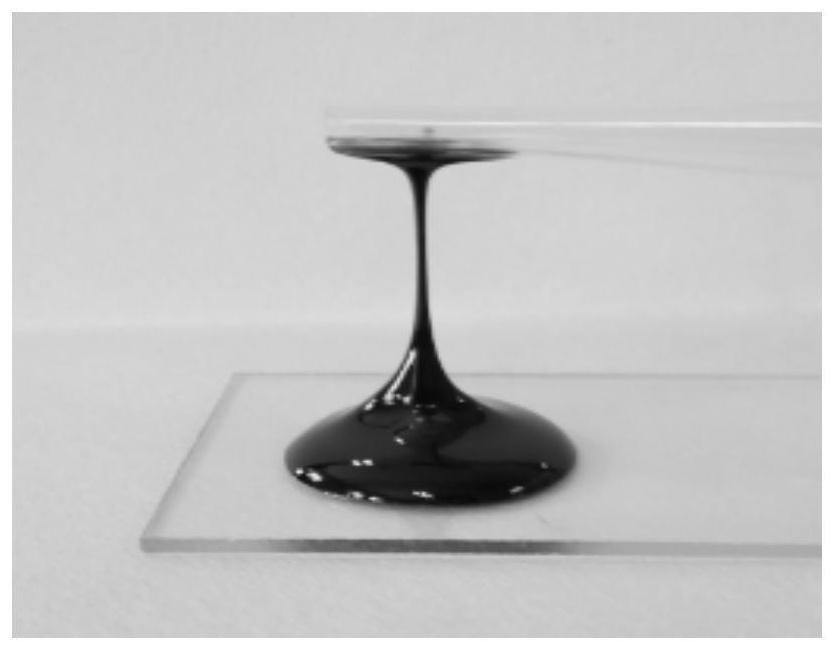

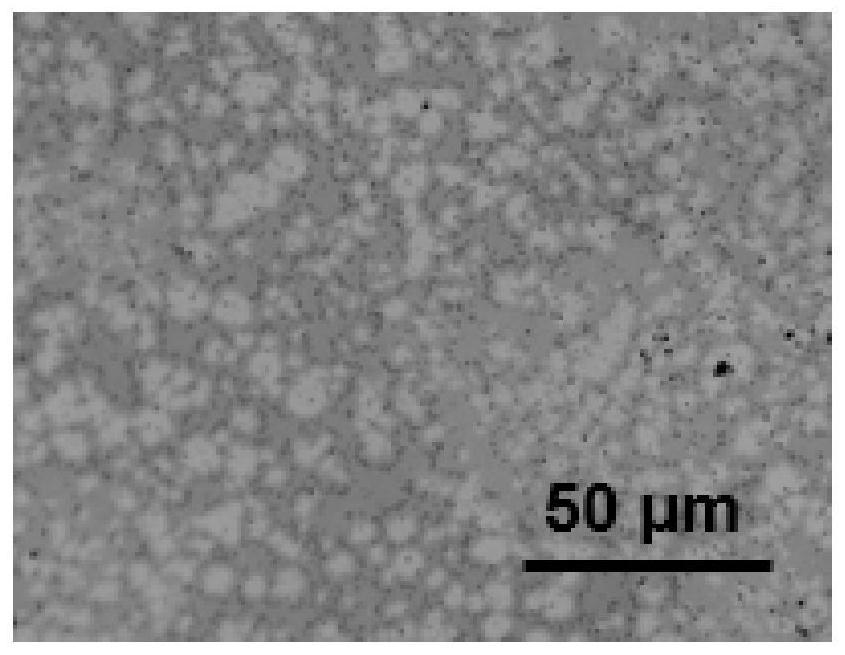

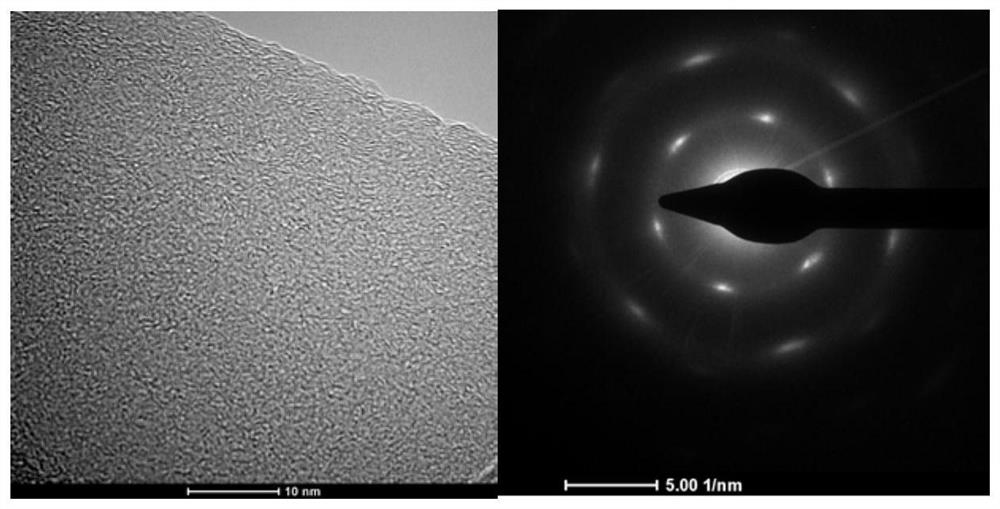

Image

Examples

Embodiment 1

[0049] Step (1) First, apply the Hummers method to oxidize the graphite to obtain graphite oxide, and then purify it with hydrochloric acid and ethanol. Dry the purified graphite oxide naturally, add ethylene glycol solvent, stir or sonicate to obtain a single-layer graphene oxide-ethylene glycol dispersion.

[0050] Take 20mL graphene oxide-ethylene glycol dispersion (1mg / mL), add 40 microliters of reducing agent hydrazine hydrate (98%), place in an oil bath at 95°C for 1h, and obtain a single-layer graphene dispersion (approx. 0.5mg / mL).

[0051] Vacuum filter the single-layer graphene dispersion until the solvent is just exhausted to obtain a graphene film solvated with ethylene glycol; place 10 mg of the film in 2 mL of dimethyl sulfoxide solvent and soak for 1 h to replace the ethylene glycol. A graphene film solvated with dimethyl sulfoxide was obtained.

[0052] Step (2) get a certain amount of DMSO solvated graphene film (as graphene quality is 5mg) and join in 5g ep...

Embodiment 2

[0060] Step (1) First, apply the Hummers method to oxidize the graphite to obtain graphite oxide, and then purify it with hydrochloric acid and ethanol. Dry the purified graphite oxide naturally, add dimethyl sulfoxide solvent, stir or sonicate to obtain a monolayer graphene oxide-dimethyl sulfoxide dispersion.

[0061] Take 20 mL of graphene oxide-dimethyl sulfoxide dispersion (1 mg / mL), place it in a reaction kettle for reduction at 165° C. for 13 h, and obtain a single-layer graphene dispersion (about 0.5 mg / mL).

[0062] The graphene dispersion was vacuum filtered until the solvent was just exhausted to obtain a graphene film solvated with dimethyl sulfoxide.

[0063] Step (2) get a certain amount of DMSO-solvated graphene film (such as graphene quality is 10mg) and join in 5g epoxy resin, then add 2mL acetone solvent, this mixing system is 1000rpm in rotating speed After stirring for 1 hour under the same conditions, ultrasonication was performed for 30 minutes under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com