A kind of alcrn/alcrsin superhard nano-composite multilayer coating and its preparation method and application

A nano-composite, multi-layer coating technology, applied in the coating, metal material coating process, vacuum evaporation plating, etc., to achieve the effects of dense film structure, excellent residual stress, huge market potential and use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

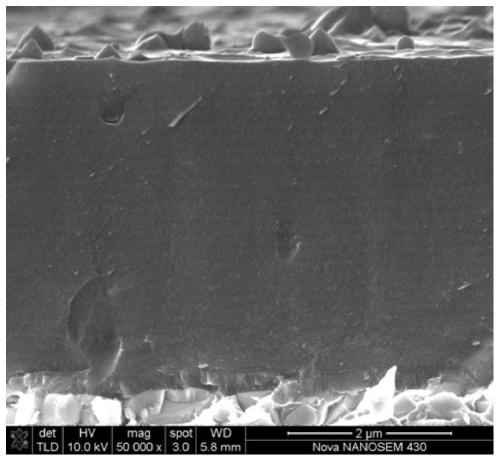

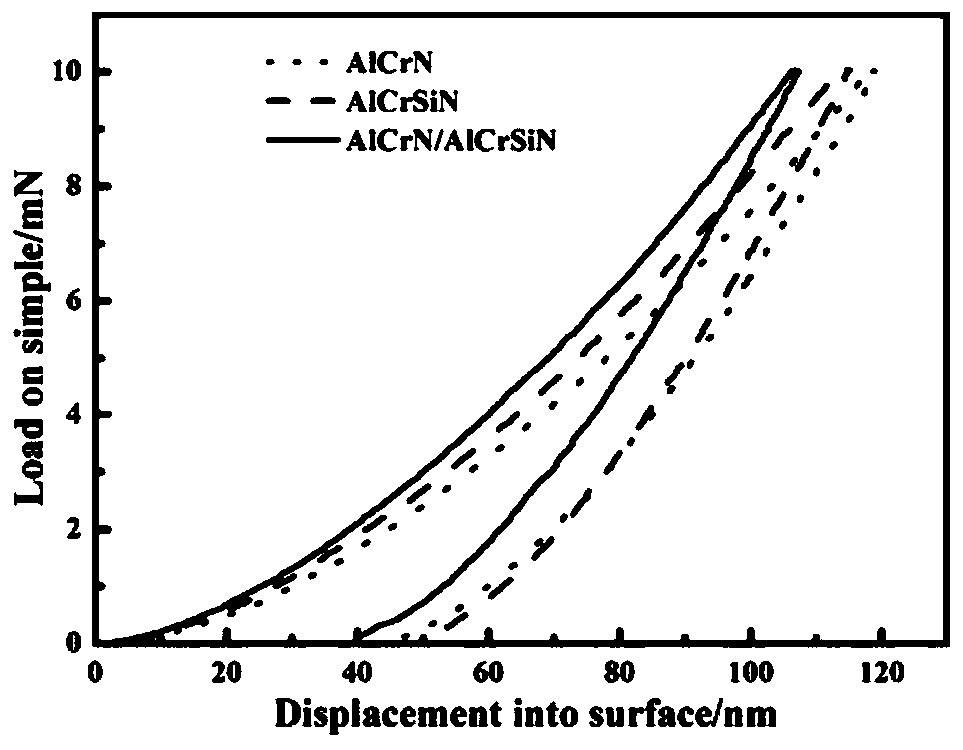

[0037]A kind of AlCrN / AlCrSiN superhard nano-composite multi-layer coating, this coating comprises substrate substrate, AlCrN transition layer and AlCrN / AlCrSiN nano-composite multi-layer function layer from bottom to top; Said transition layer is attached to WC-Co hard AlCrN coating with a thickness of 0.2 μm on a high-quality alloy or high-speed steel tool substrate; the AlCrN / AlCrSiN nanocomposite multilayer functional layer is attached to the transition layer with a thickness of 4 μm. The composition of the AlCrN / AlCrSiN nanocomposite multilayer functional layer is Al: 29at.%, Cr: 17at.%, Si: 2at.%, N: 52at.%; the AlCrN / AlCrSiN nanocomposite multilayer functional layer is modulated by The AlCrN intermediate layer and the AlCrSiN intermediate layer with a ratio of 1:1.5 are alternately deposited, and the modulation period is 30-35nm.

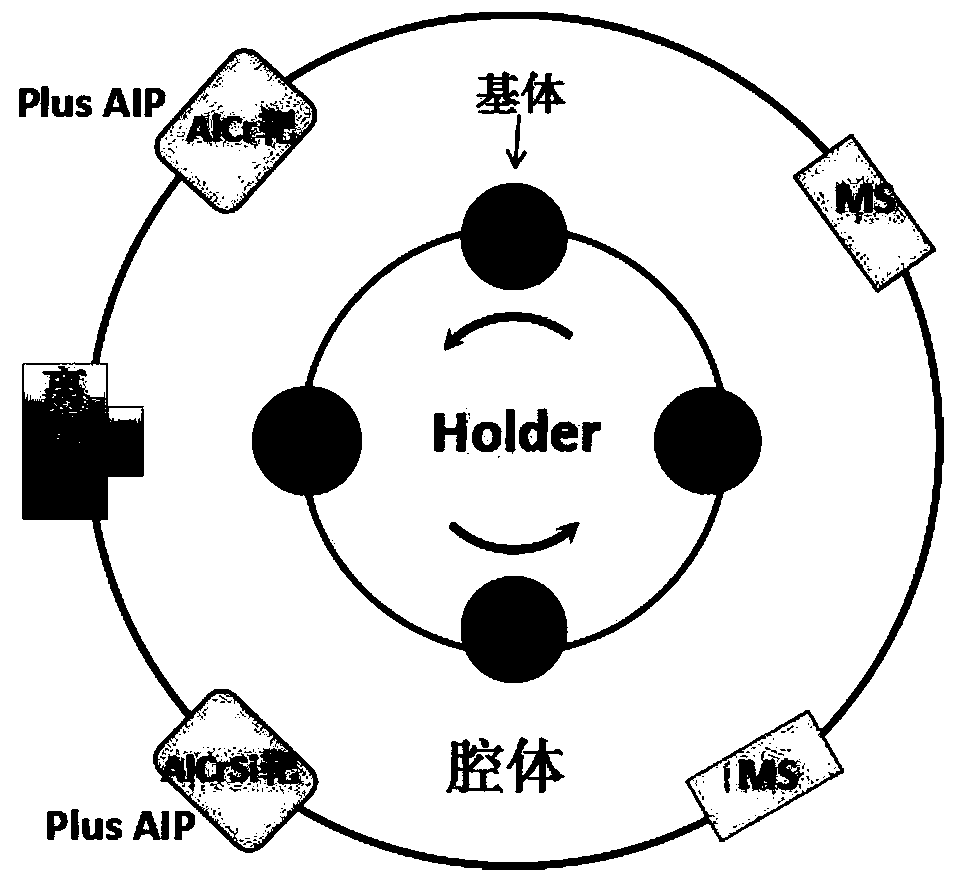

[0038] The preparation method of the above-mentioned AlCrN / AlCrSiN superhard nano-composite multi-layer coating adopts the pulse arc ion pla...

Embodiment 2

[0046] A kind of AlCrN / AlCrSiN superhard nano-composite multi-layer coating, this coating comprises substrate substrate, AlCrN transition layer and AlCrN / AlCrSiN nano-composite multi-layer function layer from bottom to top; Said transition layer is attached to WC-Co hard AlCrN coating with a thickness of 0.3 μm on a high-quality alloy or high-speed steel tool substrate; the AlCrN / AlCrSiN nanocomposite multilayer functional layer is attached to the transition layer with a thickness of 3 μm. The composition of the AlCrN / AlCrSiN nanocomposite multilayer functional layer is Al: 25at.%, Cr: 18at.%, Si: 3at.%, N: 54at.%; the AlCrN / AlCrSiN nanocomposite multilayer functional layer is modulated by The AlCrN intermediate layer and the AlCrSiN intermediate layer with a ratio of 1:1.5 are alternately deposited, and the modulation period is 27-32nm.

[0047] The preparation method of the above-mentioned AlCrN / AlCrSiN superhard nano-composite multi-layer coating adopts the pulse arc ion pl...

Embodiment 3

[0055] A kind of AlCrN / AlCrSiN superhard nano-composite multi-layer coating, this coating comprises substrate substrate, AlCrN transition layer and AlCrN / AlCrSiN nano-composite multi-layer function layer from bottom to top; Said transition layer is attached to WC-Co hard AlCrN coating with a thickness of 0.4 μm on a high-quality alloy or high-speed steel tool substrate; the AlCrN / AlCrSiN nanocomposite multilayer functional layer is attached to the transition layer with a thickness of 2 μm. The composition of the AlCrN / AlCrSiN nanocomposite multilayer functional layer is Al: 23at.%, Cr: 14at.%, Si: 2at.%, N: 56at.%; the AlCrN / AlCrSiN nanocomposite multilayer functional layer is modulated by The AlCrN intermediate layer and the AlCrSiN intermediate layer with a ratio of 1:1.5 are alternately deposited, and the modulation period is 22-28nm.

[0056] The preparation method of the above-mentioned AlCrN / AlCrSiN superhard nano-composite multi-layer coating adopts the pulse arc ion pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com