A kind of anti-pollution vacuum anti-reflection film and preparation method thereof

An anti-reflection film and anti-pollution technology, which is applied in the direction of instruments, optical components, coatings, etc., can solve the problems of poor weather resistance and poor transmission performance, and achieve high anti-pollution ability, improved weather resistance, and reduced free energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the anti-pollution vacuum anti-reflection film of this embodiment includes the following steps:

[0027] (1) In an environment with a temperature of 3°C and a relative humidity of 50%, tetraethyl orthosilicate, nitric acid, and butanol are mixed in a mass ratio of 2:0.5:20 and fully stirred, and hydrolyzed and polycondensed to obtain unmodified SiO 2 Sol A of porous particles;

[0028] (2) Add 2,2,3,3,4,4,5,5,6,6,7,7-perfluoro-1,8-octanediol to sol A to make it react with orthosilicate tetra The mass ratio of ethyl ester is 5%, stirred at room temperature for 5h, and then aged at 30°C for 12 days to obtain the modified SiO 2 Sol B of porous particles;

[0029] (3) By ultrasonic-assisted method (ultrasonic frequency 18kHz, ultrasonic power 500W, ultrasonic time 10min), 0.25g of hexafluoro-2-methylisopropyl acrylate polymer was completely dissolved in 200mL of acetone with a mass ratio of 1:1 And in the mixed solution of sec-butanol, obtain t...

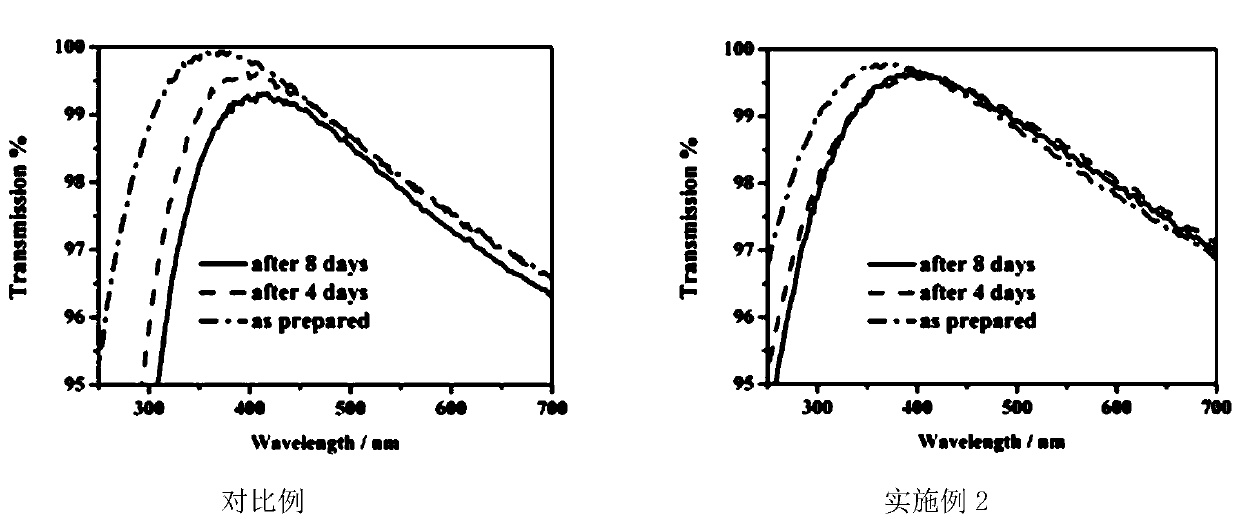

Embodiment 2

[0033] The preparation method of the anti-pollution vacuum anti-reflection film of this embodiment includes the following steps:

[0034] (1) In an environment with a temperature of 4°C and a relative humidity of 40%, tetraethyl orthosilicate, hydrochloric acid, and ethanol are mixed according to a mass ratio of 3.5:1:30 and fully stirred, and hydrolyzed and polycondensed to obtain an unmodified SiO 2 Sol A of porous particles;

[0035] (2) Add 2,2,3,3,4,4,5,5,6,6,7,7-perfluoro-1,8-octanediol to sol A to make it react with orthosilicate tetra The mass ratio of ethyl ester was 6%, stirred at room temperature for 6h, and then aged at 25°C for 14 days to obtain the modified SiO 2 Sol B of porous particles;

[0036] (3) By ultrasonic-assisted method (ultrasonic frequency 18kHz, ultrasonic power 500W, ultrasonic time 10min), 0.5g of hexafluoro-2-methylisopropyl acrylate polymer was completely dissolved in 260mL of acetone with a mass ratio of 1:1.5 And in the mixed solution of s...

Embodiment 3

[0040] The preparation method of the anti-pollution vacuum anti-reflection film of this embodiment includes the following steps:

[0041](1) In an environment where the temperature is 5°C and the relative humidity is lower than 30%, tetraethyl orthosilicate, ammonium chloride, and acetone are mixed according to the mass ratio of 5:1.5:40 and fully stirred, and hydrolyzed and polycondensed to obtain Modified SiO 2 Sol A of porous particles;

[0042] (2) Add 2,2,3,3,4,4,5,5,6,6,7,7-perfluoro-1,8-octanediol to sol A to make it react with orthosilicate tetra The mass ratio of ethyl ester is 7%, stirred at room temperature for 7h, and then aged at 20°C for 16 days to obtain the modified SiO 2 Sol B of porous particles;

[0043] (3) By ultrasonic-assisted method (ultrasonic frequency 18kHz, ultrasonic power 500W, ultrasonic time 10min), 0.75g of hexafluoro-2-methylisopropyl acrylate polymer was completely dissolved in 320mL of acetone with a mass ratio of 1:1.5 And in the mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com