A method for manufacture a lithium ion battery in which titanium nitride is deposited on that surface of a positive electrode sheet

A technology for lithium-ion batteries and positive pole pieces, applied in electrode manufacturing, secondary batteries, battery electrodes, etc., can solve the problem of limiting the high-current charge and discharge performance of lithium iron phosphate batteries, deteriorating the consistency of single-cell aging rates, and parallel branch circuits The problem of uneven current distribution among different devices can achieve the effect of improving high-current charging and discharging performance, improving temperature balance, and enhancing transport capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

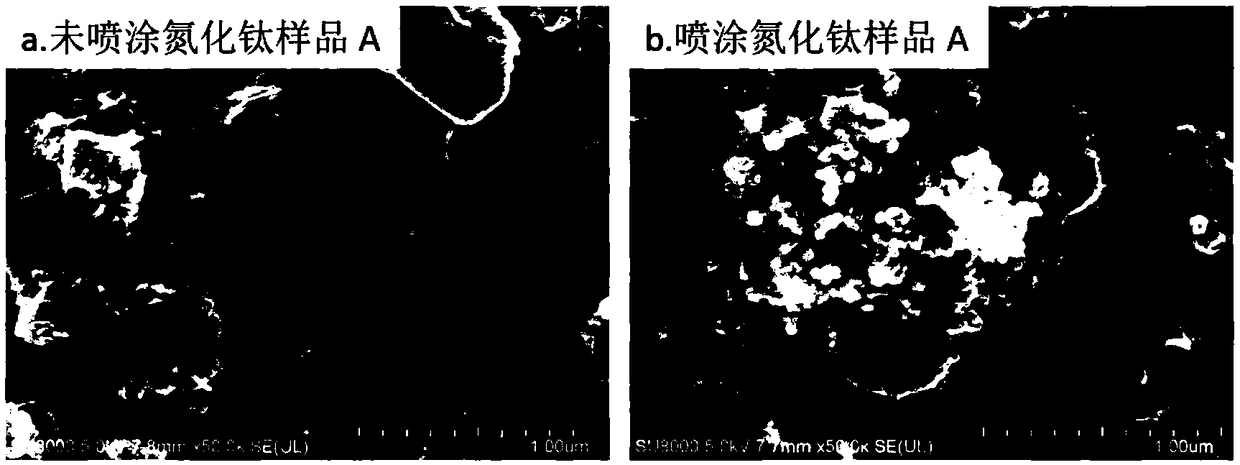

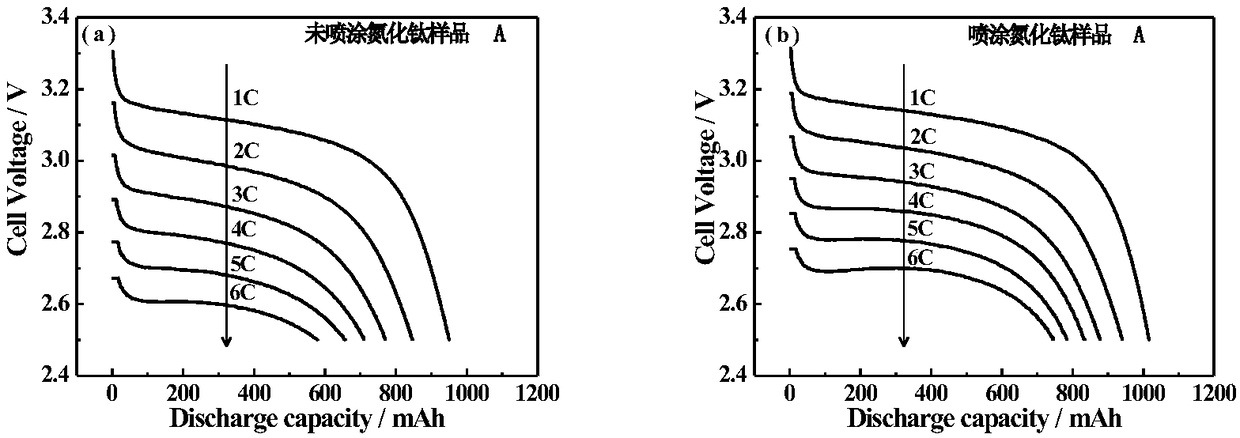

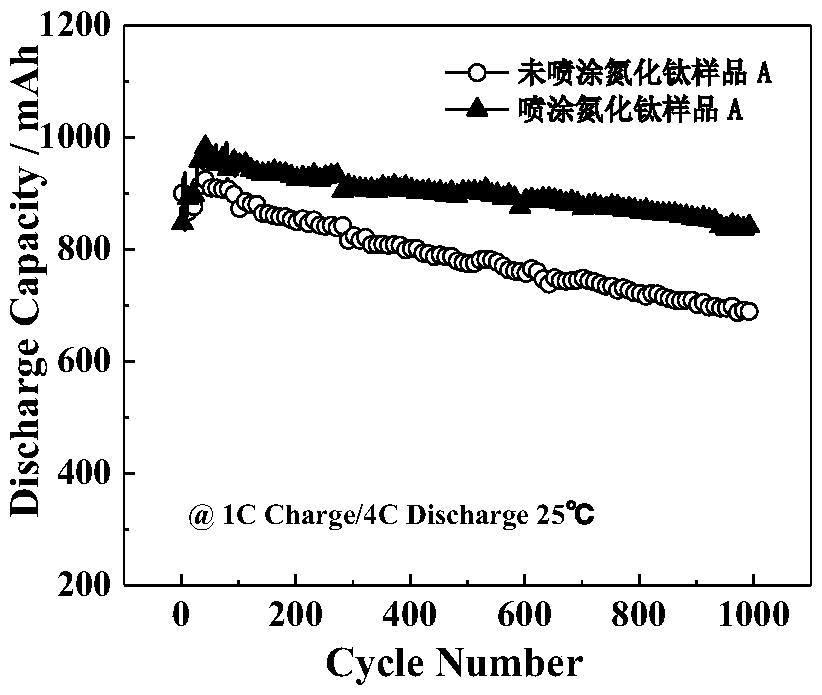

[0056] 1. Production of lithium iron phosphate positive electrode with titanium nitride deposited on the surface

[0057] 942 grams of lithium iron phosphate powder, 13 grams of conductive carbon black and 45 grams of polyvinylidene fluoride were weighed at a mass ratio of 94.2:1.3:4.5, and vacuum-dried at 100° C. for 10 hours.

[0058] Weigh 798 grams of N-methylpyrrolidone solvent and place it in a vacuum stirring tank, add polyvinylidene fluoride powder and stir, and the stirring speed is 20 Hz. After stirring for 1.5 hours, conductive carbon black was added, and stirring was continued for 3 hours at a speed of 25 Hz. Then, lithium iron phosphate powder was added, and stirring was continued for 3 hours at a rotational speed of 20 Hz and a vacuum of -0.08 Mpa to obtain a lithium iron phosphate slurry. Sieve the lithium iron phosphate slurry with a 150-mesh stainless steel screen.

[0059] The sieved lithium iron phosphate slurry was coated on both sides on a 20 micron alum...

Embodiment 2

[0074] 1. Production of lithium iron phosphate positive electrode with titanium nitride deposited on the surface

[0075] According to the mass ratio of 94.2:1.3:4.5, 942 grams of lithium iron phosphate powder, 13 grams of conductive carbon black, and 45 grams of polyvinylidene fluoride were weighed and dried in vacuum at 100° C. for 10 hours.

[0076] Weigh 798 g of N-methylpyrrolidone solvent and place it in a vacuum stirring tank, add polyvinylidene fluoride, and stir at a stirring speed of 20 Hz for 1.5 hours. Then conductive carbon black was added, and stirring was continued for 3 hours at a speed of 25 Hz. Then, lithium iron phosphate powder was added, and stirred at a stirring speed of 20 Hz and a vacuum degree of -0.08 Mpa for 3 hours to prepare a lithium iron phosphate slurry. Sieve the lithium iron phosphate slurry using a 150-mesh stainless steel screen.

[0077] Use a transfer coater to coat the sieved lithium iron phosphate slurry on a 20-micron thick aluminum f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com