Bagasse pig feed and preparation method thereof

A technology of bagasse and pig feed, which is applied in the field of livestock breeding, can solve the problems of inability to use bagasse as the main ingredient of pig feed, alcohol taste, heavy sour taste, and inability to be applied on a large scale, so as to achieve improved immunity, balanced nutrient content, good palatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

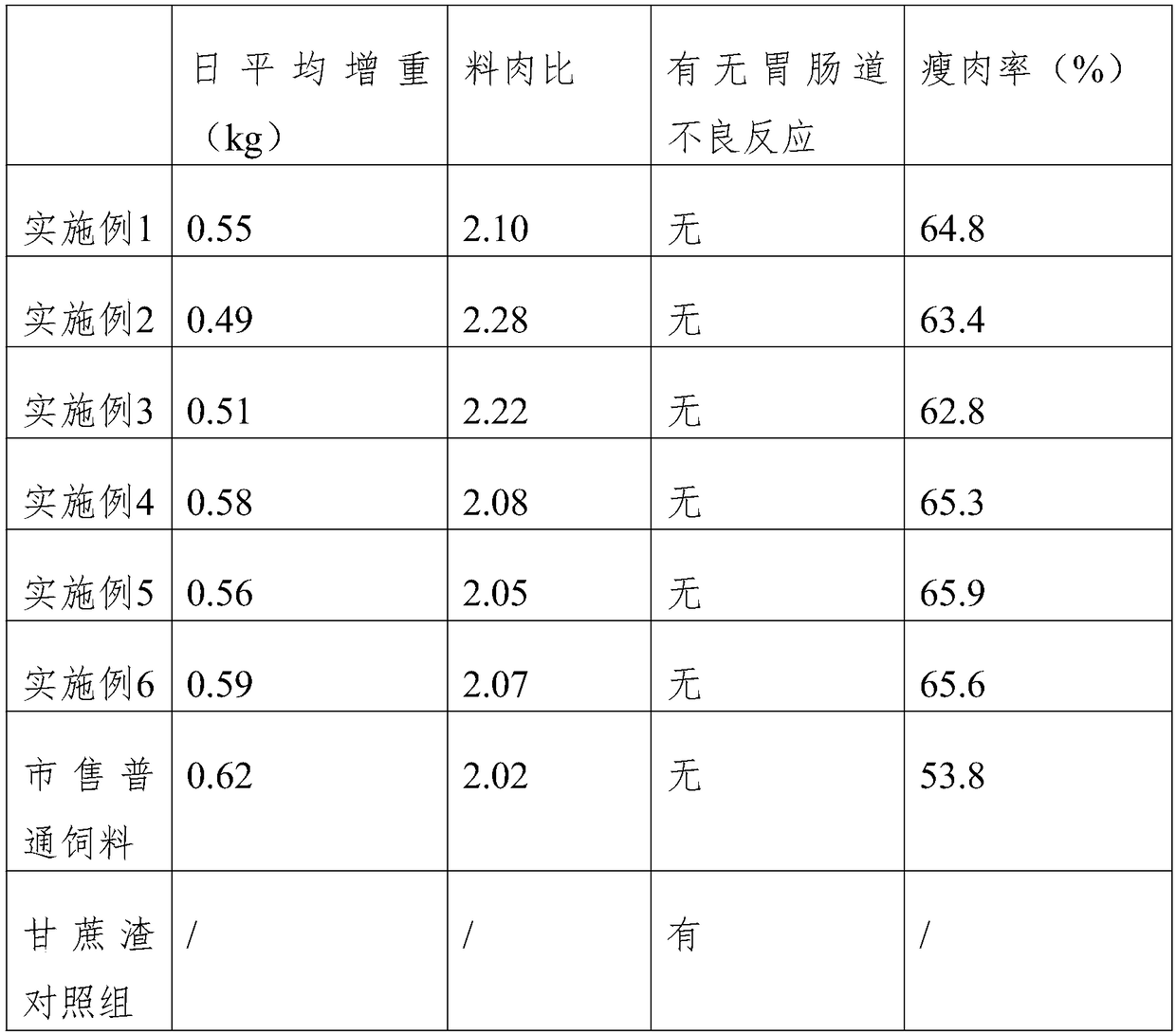

Examples

Embodiment 1

[0025] (1) Take by weighing 130kg bagasse, 15kg soybean meal, 20kg plantain taro residue, stir evenly after crushing, add water, make the mixture water content 37.5%, add 2% starter, stir well, react for 8d, then mix the mixture at 105 Heat at ℃ for 22.5min to sterilize and inactivate enzyme activity. The starter is compounded by amylase, cellulase, xylanase, pectinase, Bacillus subtilis, Bacillus licheniformis and Pichia pastoris get;

[0026] (2) 10kg of leaves of Moringa oleifera, 5kg of Citrus aurantium, 6.5kg of amomum, 8kg of shrimp shells, 12kg of wine grains, 8kg of nettles, 6kg of horse chestnut, 7kg of Vitex fruticosa, and 4kg of Hypericum perforatum are mixed to form a slurry, Mix evenly with the mixture after deactivation in step (1) according to the weight ratio of mixed slurry: mixture after enzymatic activity = 1:10;

[0027] (3) Add 1.5% sodium chloride to the mixture obtained by mixing in step (2), mix evenly, and dry to make particles with a particle size of...

Embodiment 2

[0030] (1) Take by weighing 100kg bagasse, 18kg soybean meal, 22kg plantain taro residue, stir evenly after crushing, add water, make the mixture water content 35%, add 1.5% starter, stir well, react for 10d, then mix the mixture at 90 Heating at ℃ for 30 minutes to sterilize and inactivate enzyme activity, the starter is compounded by amylase, cellulase, xylanase, pectinase, Bacillus subtilis, Bacillus licheniformis and Pichia pastoris ;

[0031] (2) 8kg leaves of Moringa oleifera, 3kg Citrus aurantium, Amomum 5kg, shrimp shells 6kg, wine grains 10kg, nettle 9kg, horse chestnut 7kg, Vitex fringata 8kg, and Hypericum perforatum 5kg are mixed to form a slurry, and mixed with The mixture after deactivation in step (1) is uniformly mixed according to the weight ratio of mixed slurry: mixture after enzymatic activity = 1:7;

[0032] (3) Add 1% sodium chloride to the mixture obtained by mixing in step (2), mix evenly, and dry to make particles with a particle size of 500-700 μm. ...

Embodiment 3

[0035] (1) Take by weighing 160kg bagasse, 12kg soybean meal, 18kg plantain taro residue, stir evenly after crushing, add water to make the water content of the mixture 40%, add 2.5% starter, stir well, react for 7d, then mix the mixture at 120 Heat at ℃ for 15 minutes to sterilize and inactivate the enzyme activity. The starter is compounded by amylase, cellulase, xylanase, pectinase, Bacillus subtilis, Bacillus licheniformis and Pichia pastoris ;

[0036] (2) 12kg of Moringa leaves, 7kg of Citrus aurantii, 8kg of amomum, 10kg of shrimp shells, 14kg of wine lees, 7kg of nettles, 5kg of horse chestnut, 6kg of Vitex fruticosa, and 3kg of Hypericum perforatum are mixed to form a slurry, and mixed with The mixture after deactivation in step (1) is uniformly mixed according to the weight ratio of mixed slurry: mixture after enzymatic activity = 1:13;

[0037] (3) Add 2% sodium chloride to the mixture obtained by mixing in step (2), mix evenly, and dry to make particles with a par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com