A kind of highly sensitive chitosan-based sensing material and its preparation method and application

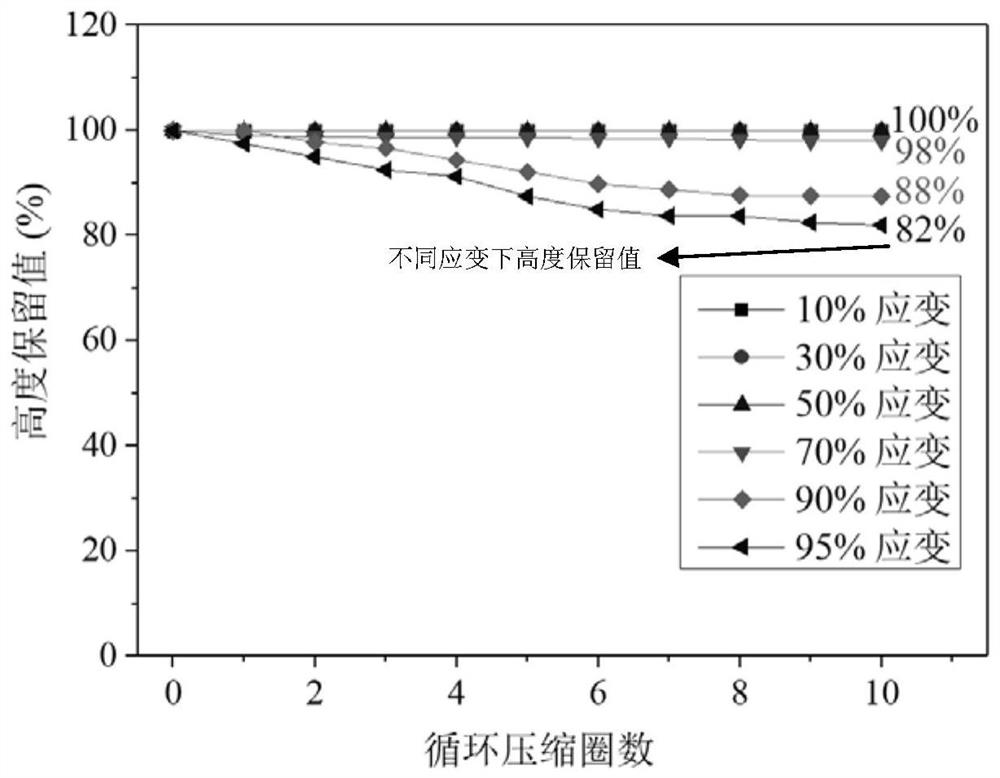

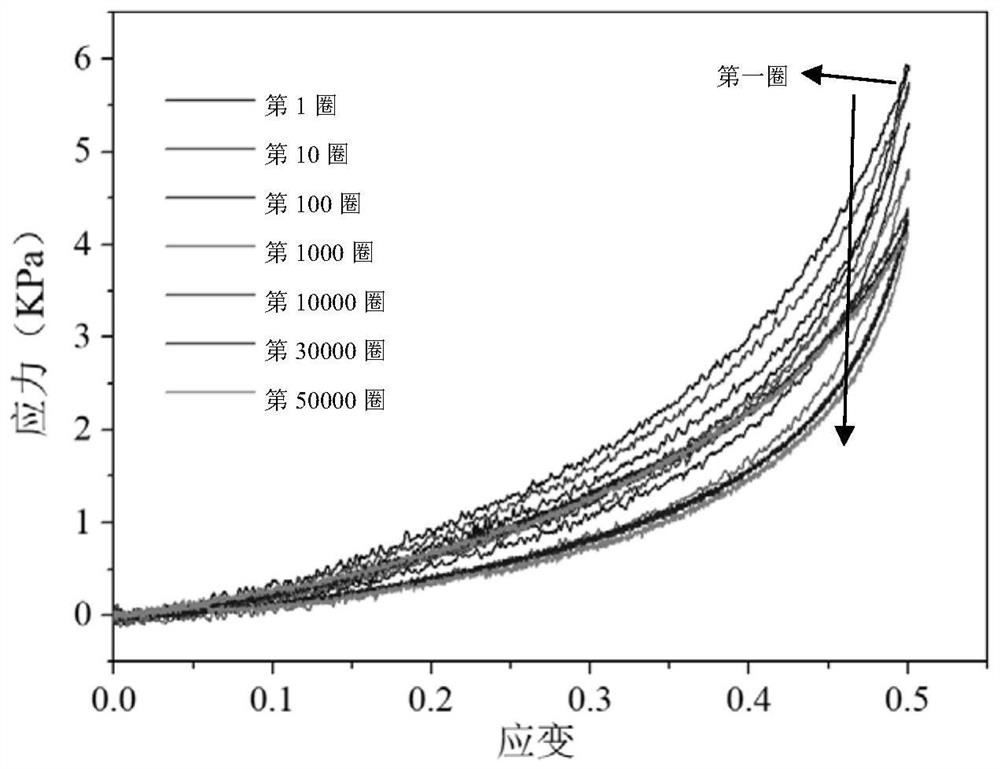

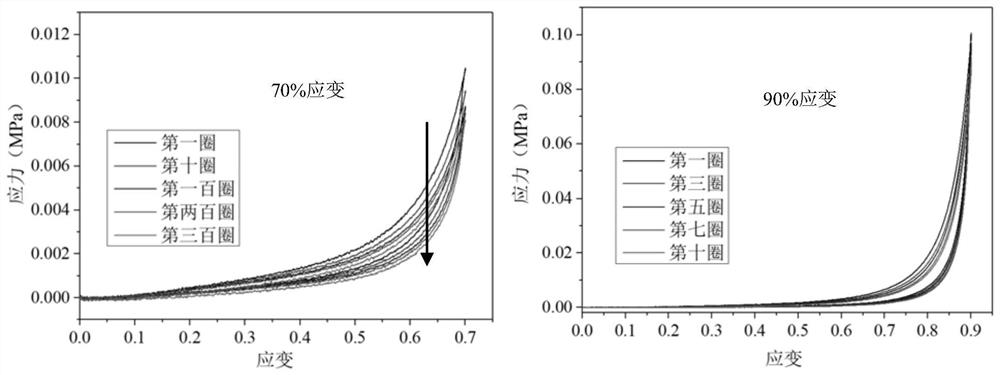

A technology of sensitive chitosan-based and sensing materials, applied in the field of chitosan-based sensing materials and their preparation, can solve the problems of inability to achieve high-sensitivity linear sensitivity, difficulty in structural design and control, poor mechanical properties, etc., and achieve Excellent cycle stability, high compressibility, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) adding cellulose nanocrystallites into water, and mechanically stirring to obtain a cellulose nanocrystallite suspension with a dispersion concentration of 0.5%;

[0041] (2) FeCl 3 ·6H 2 O is dissolved in the above-mentioned cellulose nanocrystal suspension, the concentration is 0.004mol / L, to obtain FeCl 3 / Cellulose nanocrystal suspension;

[0042] (3) under high-speed stirring (rotational speed is 800rpm), to the above-obtained FeCl 3 Slowly add 0.5% chitosan to the cellulose nanocrystal suspension, stir at high speed until dissolved, and obtain FeCl 3 / chitosan / cellulose nanocrystal suspension;

[0043] (4) the above FeCl 3 The chitosan / cellulose nanocrystal suspension is placed in a plastic box, the box is fastened to the outer wall of the metal box, and liquid nitrogen is poured into the metal box for freezing (freezing), and the solution is frozen after it is completely frozen. Drying (-58°C, vacuum 0.22mbar, time 16 hours) to obtain FeCl 3 / Chito...

Embodiment 2

[0049] (1) adding cellulose nanocrystallites into ultrapure water, and mechanically stirring to obtain a cellulose nanocrystallite suspension with a dispersion concentration of 0.5%;

[0050] (2) FeCl 3 ·6H 2 O is dissolved in the above-mentioned cellulose nanocrystal suspension, and the concentration is 0.008mol / L to obtain FeCl 3 / Cellulose nanocrystal suspension;

[0051] (3) under high-speed stirring (rotational speed is 800rpm) to the above-obtained FeCl 3 Slowly add 0.5% chitosan to the cellulose nanocrystal suspension, stir at high speed until dissolved, and obtain FeCl 3 / chitosan / cellulose nanocrystal suspension;

[0052] (4) the above FeCl 3 The chitosan / cellulose nanocrystal suspension is placed in a plastic box, the box is fastened to the outer wall of the metal box, and liquid nitrogen is poured into the metal box for freezing (freezing), and the solution is frozen after it is completely frozen. Drying (-58°C, vacuum 0.22mbar, time 16 hours) to obtain Fe...

Embodiment 3

[0056] (1) adding cellulose nanocrystallites to ultrapure water, and mechanically stirring to obtain a cellulose nanocrystallite suspension with a dispersion concentration of 0.4%;

[0057] (2) FeCl 3 ·6H 2 O is dissolved in the above-mentioned cellulose nanocrystal suspension, the concentration is 0.004mol / L, to obtain FeCl 3 / Cellulose nanocrystal suspension;

[0058] (3) under high-speed stirring (rotational speed is 800rpm) to the above-obtained FeCl 3 Slowly add 0.6% chitosan to the cellulose nanocrystal suspension, stir at high speed until dissolved, and obtain FeCl 3 / chitosan / cellulose nanocrystal suspension;

[0059] (4) the above FeCl 3 The chitosan / cellulose nanocrystal suspension is placed in a plastic box, the box is fastened to the outer wall of the metal box, and liquid nitrogen is poured into the metal box for freezing (freezing), and the solution is frozen after it is completely frozen. Drying (-58°C, vacuum 0.22mbar, time 16 hours) to obtain FeCl 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com