Magnesium-doped strontium titanate ceramic powder, and preparation method and application thereof

A technology of ceramic powder and strontium acid, which is applied in the field of preparation of ceramic powder materials, can solve problems such as large temperature coefficient, dielectric loss, and changing material properties, and achieve good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

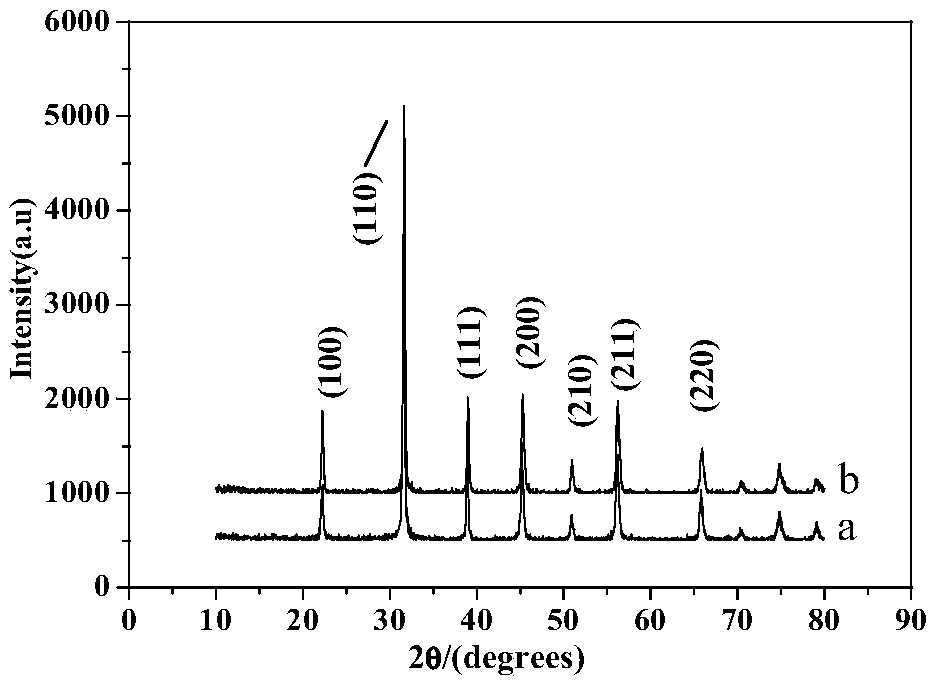

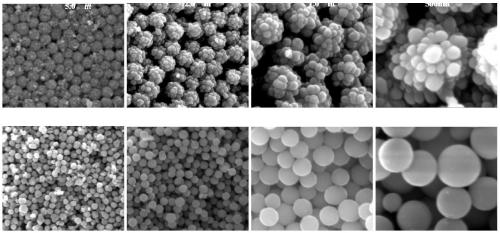

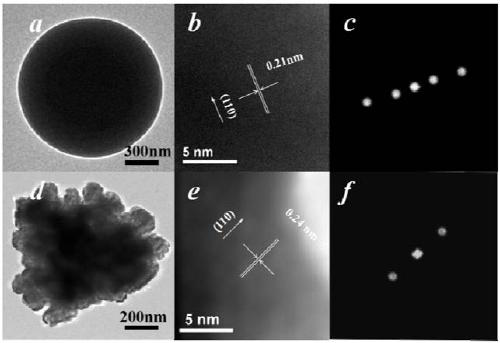

[0065] Example 1 Preparation of custard apple fruit-shaped magnesium-doped strontium titanate

[0066] Anhydrous SrCl 2 And MgCl 2 Dissolved in ultrapure water, TiCl 4 Dissolve in 0.3mol / L HCl solution, respectively make 0.5mol / L solution. By mole ratio [Sr 2+ ]:[Mg 2+ ]+[Ti 4+ ] = 1.0, [Mg 2+ ]:[Mg 2+ ]+[Ti 4+ ] = 0.02 Remove the above SrCl separately 2 Solution 2.04mL and MgCl 2 Solution 0.04mL, 2.0mLTiCl 4 Mix the solution and 1.0mL glycerol evenly, slowly add 30mL 0.6mol / L NaOH solution, mix well and place in a high pressure reactor lined with tetrafluoroethylene, keep the total volume of the solution at 35mL, magnetically stir for 10mins, and install the kettle , Seal the kettle, heat it up to 200℃ and react for 6h after sealing. After the reaction is completed, the obtained precipitate is filtered, washed, and dried in vacuum at 60° C., to obtain a white powder of custard apple-like magnesium-doped strontium titanate, labeled as SMT1.

Embodiment 2

[0067] Example 2 Preparation of spherical magnesium-doped strontium titanate

[0068] The difference from the method in Example 1 is that the concentration of NaOH is 1.5mol / L, the additive is changed from glycerol to 1.5mL ethanol, the reaction time is extended to 8h, and the reaction temperature is changed to 180°C to obtain spherical magnesium-doped titanic acid. Strontium, labeled SMT2.

Embodiment 3

[0069] Example 3 Preparation of Custard Apple-like Magnesium Doped Strontium Titanate

[0070] Anhydrous SrCl 2 And MgCl 2 Dissolved in ultrapure water, TiCl 4 Dissolve in 0.3mol / L HCl solution, respectively make up 0.7mol / L solution. By mole ratio [Sr 2+ ]:[Mg 2+ ]+[Ti 4+ ] = 1.0, [Mg 2+ ]:[Mg 2+ ]+[Ti 4+ ] = 0.02 Remove the above SrCl separately 2 Solution 2.1mL and MgCl 2 Solution 0.04mL, 2.0mLTiCl 4 Mix the solution and 1.0mL glycerol evenly, slowly add 30mL 0.6mol / L NaOH solution, mix well and place in a high pressure reactor lined with tetrafluoroethylene, keep the total volume of the solution at 35mL, magnetically stir for 10mins, and install the kettle , Seal the kettle, heat it up to 200℃ and react for 7h after sealing. After the reaction is completed, the obtained precipitate is filtered, washed, and dried in vacuum at 60° C., to obtain a white powder of custard apple-like magnesium-doped strontium titanate, labeled as SMT1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com