Acrylate based hydroxyalkyl acid ester reactive diluent and preparation method and application thereof

A technology of hydroxyalkyl esters and reactive diluents, which is applied in the field of waste ultraviolet light curing, can solve problems such as hazards and complex processes, and achieve the effects of low equipment requirements, stable preparation process, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

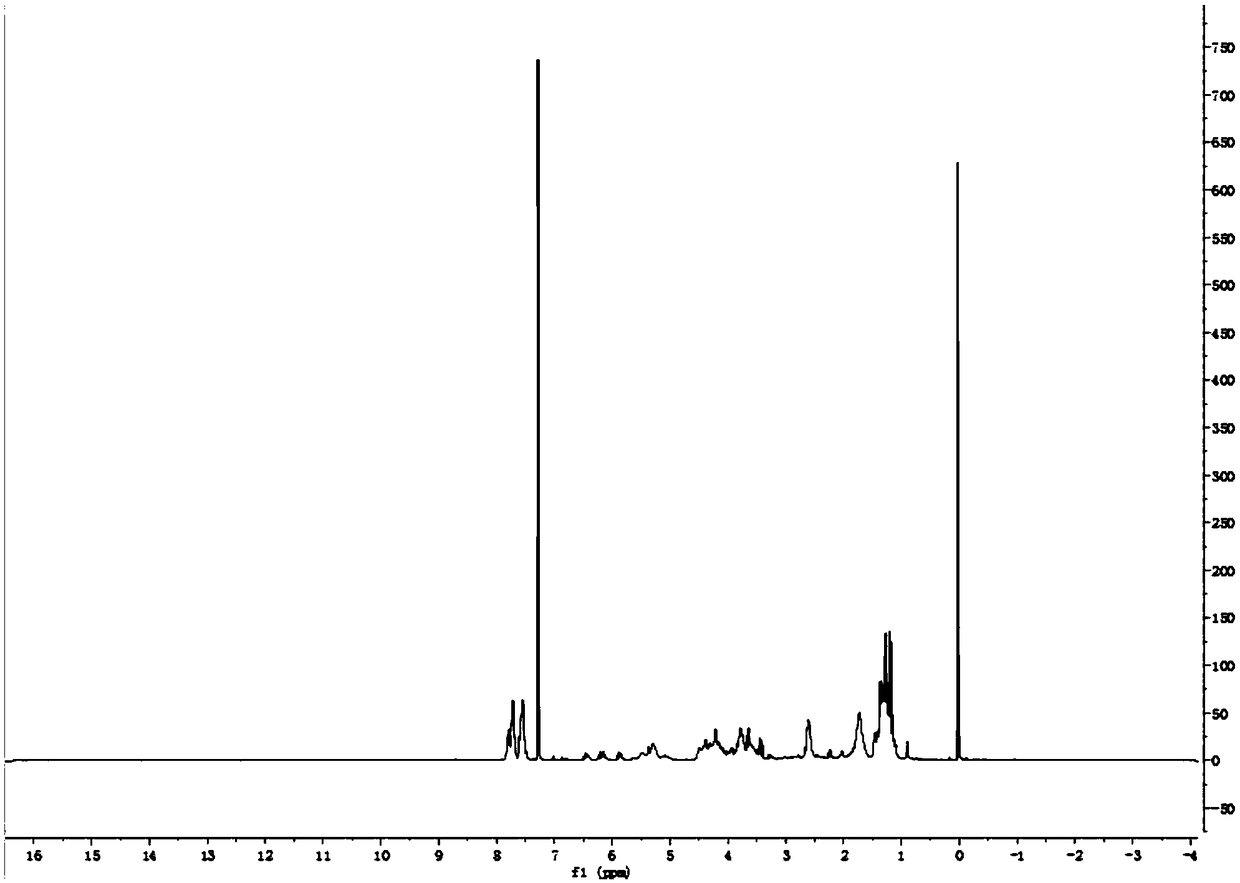

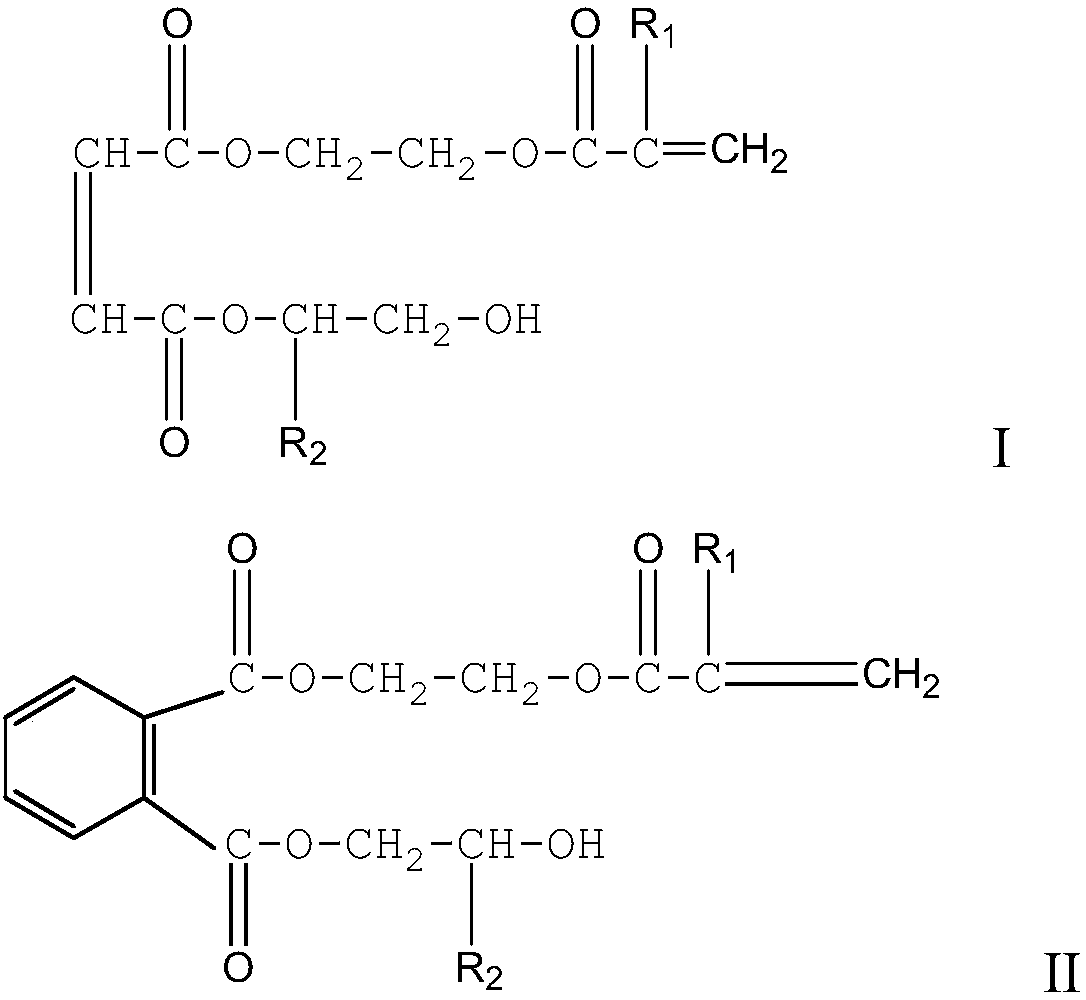

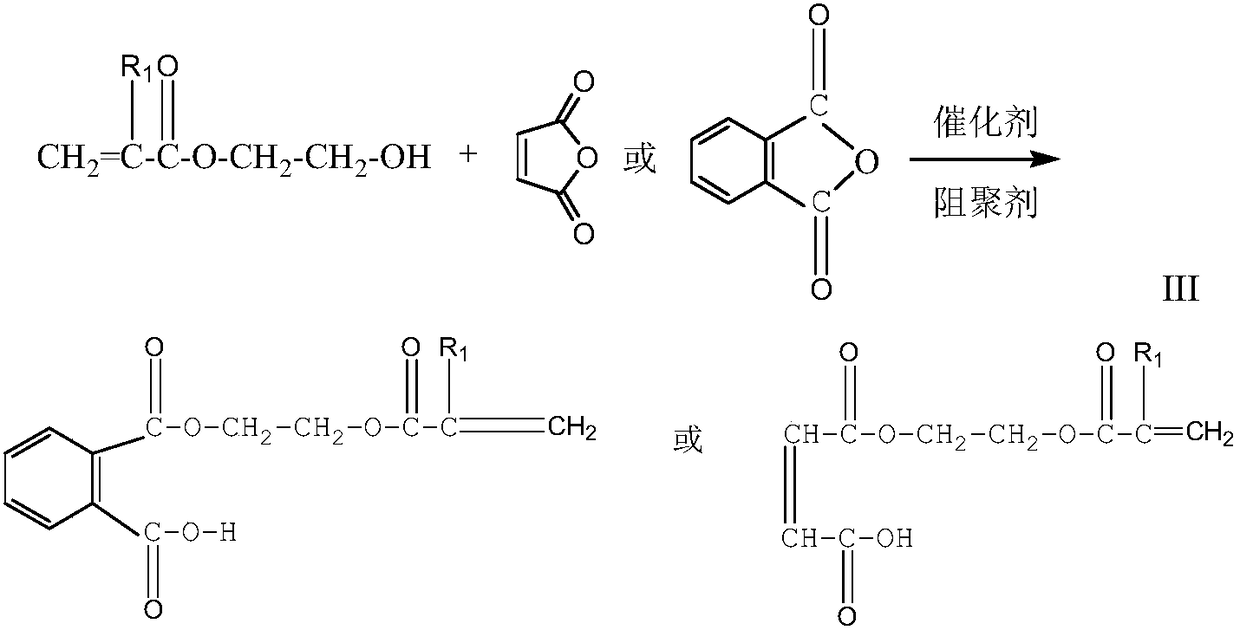

[0032] The preparation method of 1-hydroxyethyl acrylate, 4-hydroxyethyl maleate:

[0033] (1) Esterification reaction: Weigh 97g maleic anhydride solid, 116g hydroxyethyl acrylate respectively, then join the hydroxyethyl acrylate of 116g in the dry reactor, then add the quality that is esterification raw material (butadiene Acrylic anhydride and hydroxyethyl acrylate) 2.0% triethylamine and 0.3% p-hydroxyanisole, stir and heat up to 70°C, drop in 97g maleic anhydride solid in several times, keep warm at 75-85°C for 1 ~3h, until the acid value is in the range of 261~264mgKOH / g, the esterification reaction is considered to be completed.

[0034] (2) Alkoxylation reaction: add triphenylphosphine equivalent to 0.8% of the total mass of the target product in the esterified product obtained in step (1), and the reaction temperature is controlled at 80-90° C. Add a small amount of ethylene oxide, and then continue to add 44g of ethylene oxide to carry out alkoxylation reaction afte...

Embodiment 2

[0036] The preparation method of 1-hydroxypropyl acrylate group, 4-hydroxypropyl maleate:

[0037](1) Esterification reaction: Weigh 97g maleic anhydride solid, 130g hydroxypropyl acrylate respectively, then join the hydroxypropyl acrylate of 130g in the dry reactor, then add quality is esterification raw material (cis-butyl Acrylic anhydride and hydroxypropyl acrylate) 1.0% p-toluenesulfonic acid and 0.8% hydroquinone, stir and heat up to 75°C, drop 97g of maleic anhydride solid in several times, keep warm at 75-85°C for 1 ~3h, until the acid value is in the range of 245~250mg KOH / g, the esterification reaction is considered to be completed.

[0038] (2) Alkoxylation reaction: add triphenylphosphine equivalent to 0.5% of the total mass of the target product in the esterified product obtained in step (1), and control the reaction temperature at 75 to 85° C. Add a small amount of propylene oxide, and then continue to add 60g of propylene oxide to carry out the alkoxylation rea...

Embodiment 3

[0040] The preparation method of 1-hydroxyethyl methacrylate, 4-hydroxypropyl phthalate:

[0041] (1) Esterification reaction: Weigh 148g of phthalic anhydride solids and 132.6g of hydroxyethyl methacrylate respectively, then add 132.6g of hydroxyethyl methacrylate into the dry reactor, and then add a mass of Esterification raw materials (phthalic anhydride and hydroxyethyl methacrylate) 1.0% triphenylphosphine and 1.0% p-tert-butylcatechol, stirred and heated to 70 °C, and 148g phthalate For acid anhydride solids, keep warm at 80-90°C for 1-3 hours until the acid value is within the range of 200-204 mgKOH / g, the esterification reaction is considered to be completed.

[0042] (2) Alkoxylation reaction: add urotropine equivalent to 1.0% of the total mass of the target product in the esterified product obtained in step (1), and the reaction temperature is controlled at 70-80° C. Add a small amount of propylene oxide, and then continue to add 61g of propylene oxide to carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com