Organic inorganic nanometer composite hybrid waterproof leak stopping gel, and preparation method thereof

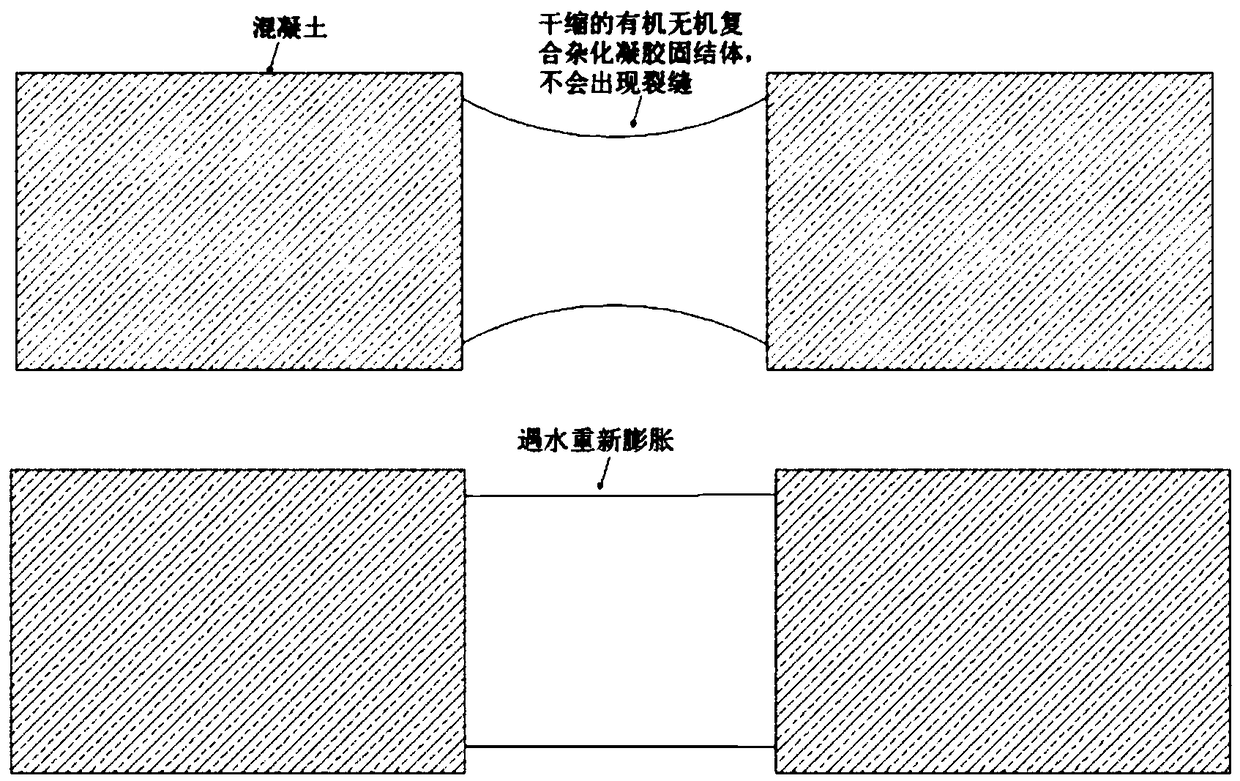

An inorganic nano, waterproof plugging technology, applied in the field of organic-inorganic nano-composite hybrid waterproof plugging gel and its preparation, can solve the problems of dry shrinkage cracking, poor compressive strength, etc., and achieve improved water absorption, strength, and good durability , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

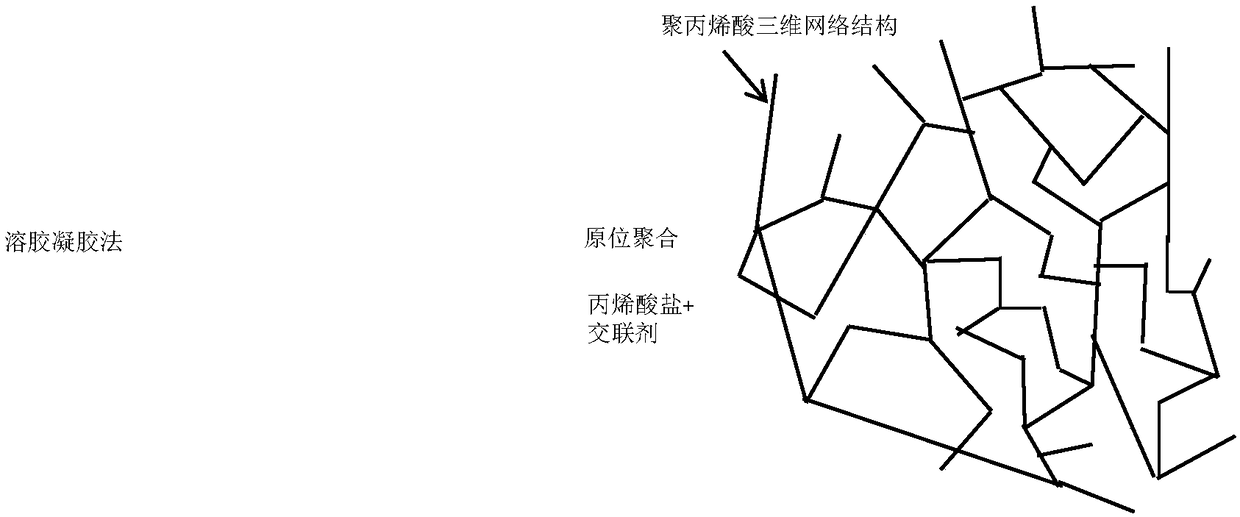

Method used

Image

Examples

Embodiment 1

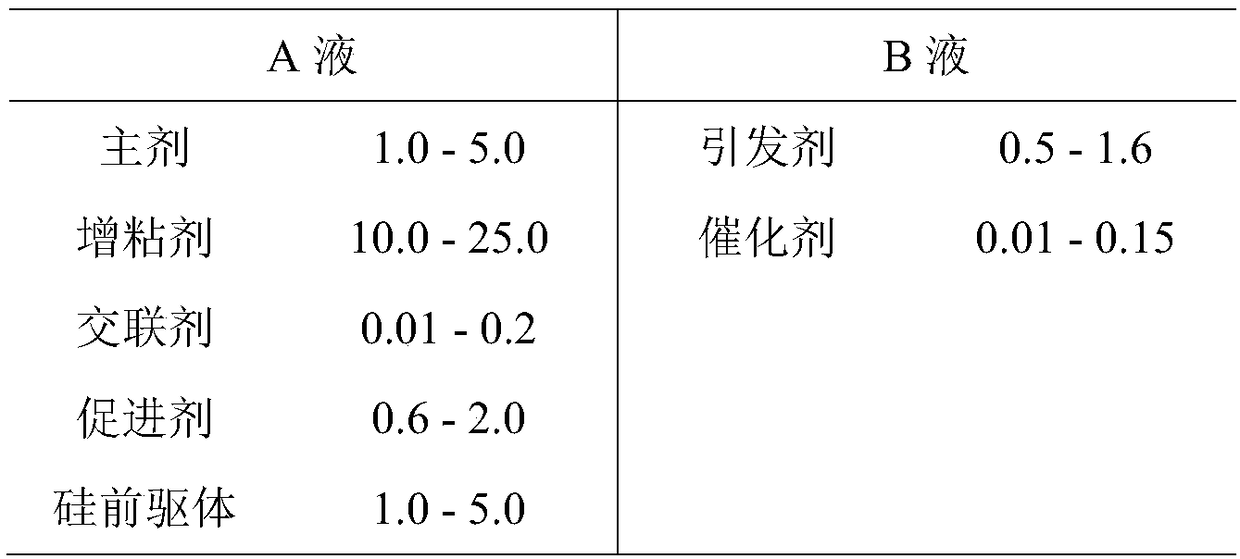

[0026] Step a: Weigh 5g of calcium acrylate and magnesium acrylate, 0.2g of N,N'-methylenebisacrylamide and 22g of acrylic acid multi-polymer emulsion and mix them uniformly in distilled water, and add a certain amount of silica sol dropwise under normal temperature stirring , and then drop triethanolamine in different parts by mass. Stir for 30 minutes to make it fully mixed to prepare 50g of liquid A.

[0027] Step b: Weigh 1.5g of ammonium persulfate and 0.1g of ferrous sulfate, dissolve them in 48.4g of distilled water, and prepare B solution.

[0028] Step c: Pour the liquid A prepared in step a and the liquid B prepared in step b into a 100ml separating funnel respectively, then quickly open the separating valve, and the liquids A and B are fully mixed under stirring. Test the setting time with the inverted cup method.

[0029] It can be seen from Table 2 that with the increase of the accelerator content, the gel setting time is shortened, even within 3S. However, the...

Embodiment 2

[0031] Step a: Weigh 5g of calcium acrylate and magnesium acrylate, 0.2g of N,N'-methylenebisacrylamide and 22g of acrylic acid multi-polymer emulsion and mix them uniformly in distilled water, and add silicon with different mass fractions dropwise under normal temperature stirring Sol, then dropwise add 1.5g triethanolamine. Stir for 30 minutes to make it fully mixed to prepare 50g of liquid A.

[0032] Step b: Weigh 1.5g of ammonium persulfate and 0.1g of ferrous sulfate, dissolve them in 48.4g of distilled water, and prepare B solution.

[0033] Step c: Pour the liquid A prepared in step a and the liquid B prepared in step b into a 100ml separating funnel respectively, then quickly open the separating valve, and the liquids A and B are fully mixed under stirring. Test the setting time with the inverted cup method.

[0034] Table 3 shows that the gel setting time is related to the content of silica nanoparticles. As the silica content increases, the setting time decreases. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com