Preparation method for magnetic plastic particles

A plastic particle and magnetic technology, applied in the field of plastic processing, to achieve the effect of enhancing tensile strength, enhancing surface acid and alkali resistance, and enhancing bonding type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

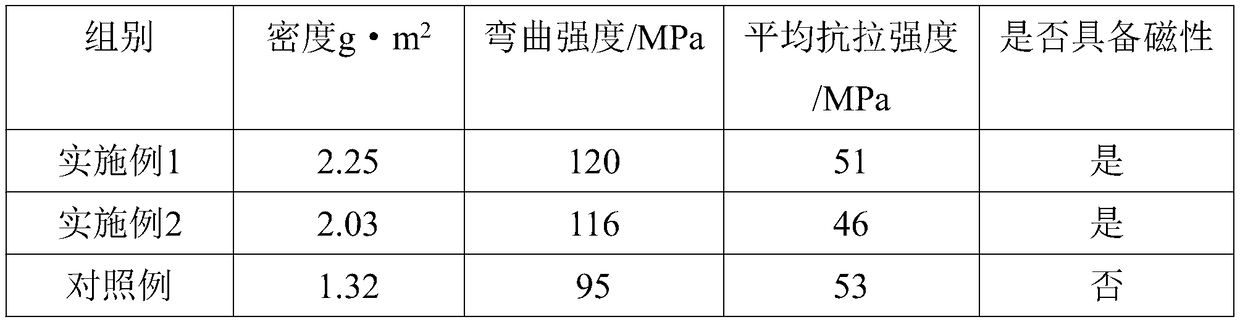

Examples

Embodiment 1

[0029] A method for preparing magnetic plastic particles, comprising the steps of:

[0030] Put the waste plastics into the clear water pool, pour the mixed solution composed of cationic polyacrylamide, sodium chloride, and hydrochloric acid with a mass fraction of 3%, the ratio of the mixed solution to water is 100:2; cationic polyacrylamide, chlorine The mass ratio of sodium chloride and hydrochloric acid with a mass fraction of 3% is 5:1:1;

[0031] Take it out, then dry it, and control the moisture content of the material to 1%-4%;

[0032] Throw it into a plastic shredder for crushing;

[0033] Put the crushed waste plastics, heavy calcium carbonate, and organic solvent into a plastic granulator, and the organic solvent and waste plastics undergo a catalytic reaction to slowly soften and recycle the waste plastics;

[0034] Input the softened waste plastics into the screw electric heating melting machine for heating to speed up the softening speed of waste plastics;

...

Embodiment 2

[0044] A method for preparing magnetic plastic particles, comprising the steps of:

[0045] Put the waste plastics into the clear water pool, pour the mixed solution composed of cationic polyacrylamide, sodium chloride, and hydrochloric acid with a mass fraction of 3%, the ratio of the mixed solution to water is 100:3; cationic polyacrylamide, chlorine The mass ratio of sodium chloride and hydrochloric acid with a mass fraction of 3% is 10:5:3;

[0046] Take it out, then dry it, and control the moisture content of the material to 1%-4%;

[0047] Throw it into a plastic shredder for crushing;

[0048] Put the crushed waste plastics, heavy calcium carbonate, and organic solvent into a plastic granulator, and the organic solvent and waste plastics undergo a catalytic reaction to slowly soften and recycle the waste plastics;

[0049] Input the softened waste plastics into the screw electric heating melting machine for heating to speed up the softening speed of waste plastics;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com