Method for improving purity of AlN monocrystals by using reducing gas

A single-crystal, high-purity technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of serious light absorption, unfavorable preparation of optoelectronic devices, etc., to improve optical quality, expand the application of AlN crystal, The effect of reducing the content of impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

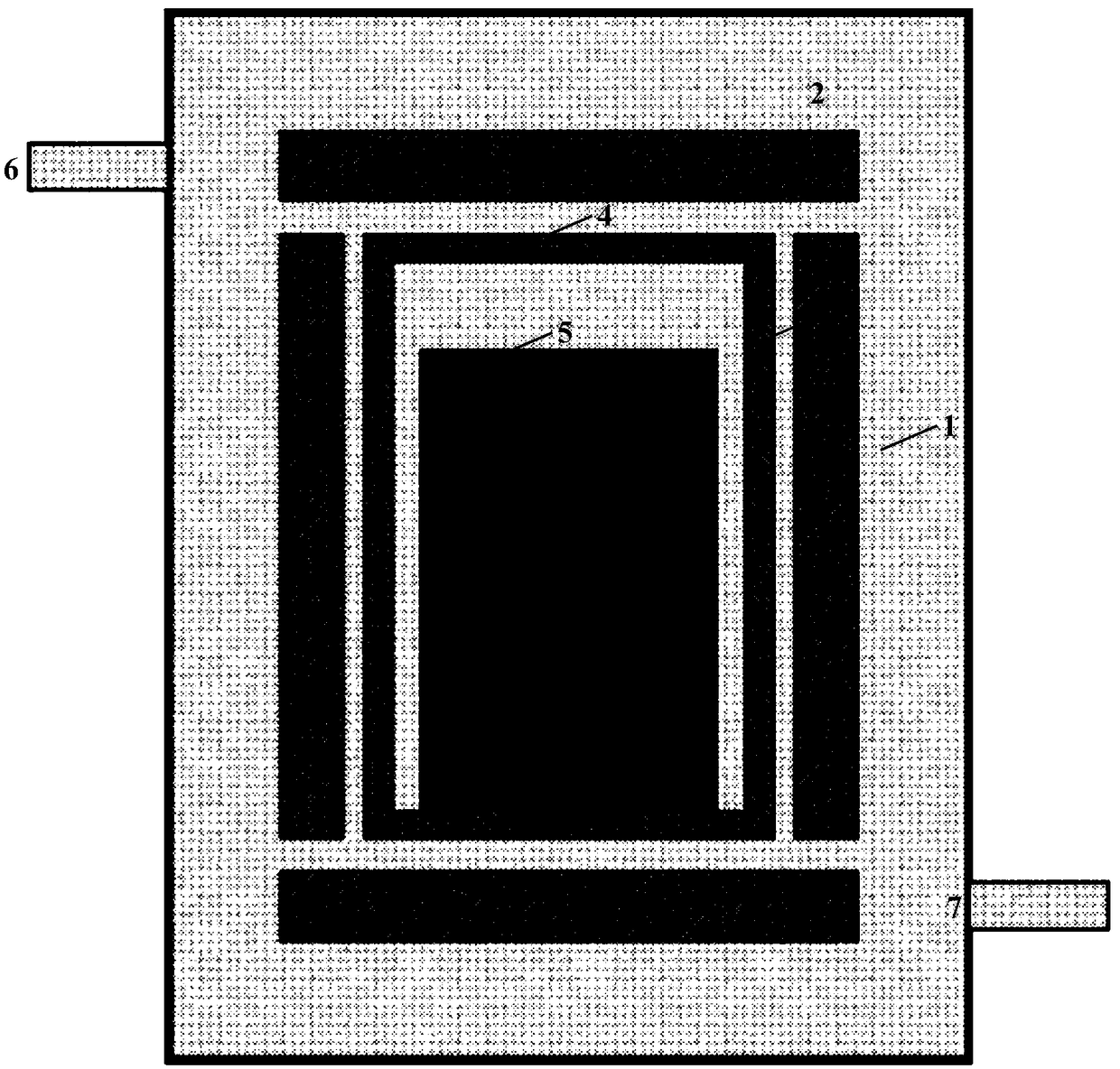

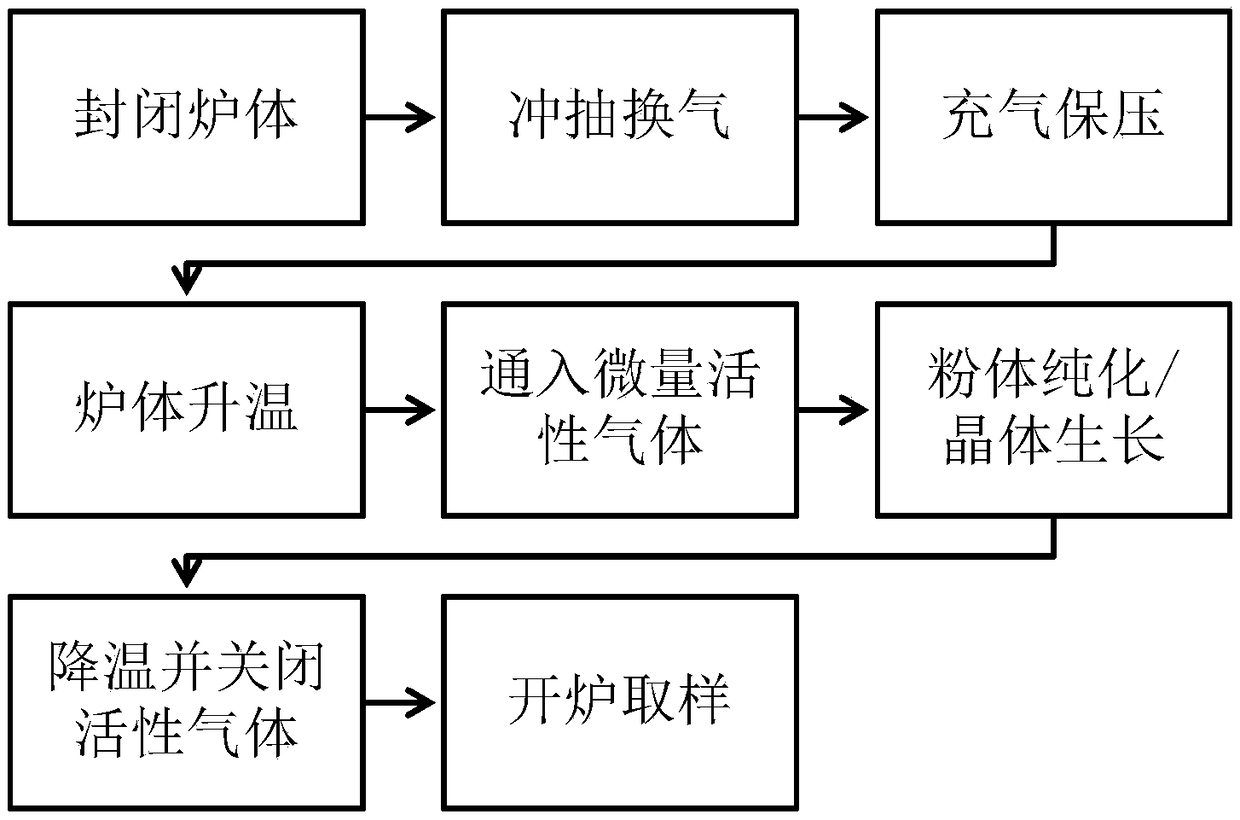

[0033] Embodiment 1 graphite furnace purification AlN powder (using methane or acetylene)

[0034] 1) Furnace charging and ventilation:

[0035] Put the tantalum carbide crucible with high-purity AlN source powder into the furnace body and close the furnace body, vacuumize the furnace body environment to 1 Torr, and fill high-purity nitrogen gas to 500 Torr, and replace the atmosphere in the cavity by filling and pumping for 3 to 5 times. The last 1 vacuum up to 10 -4 Torr;

[0036] 2) The furnace body is inflated and maintained:

[0037] After stopping the vacuuming of the furnace body, feed high-purity nitrogen gas or a mixed gas of high-purity nitrogen gas / high-purity argon gas with a ratio range of 0.1 to 0.9 into the furnace body to form an ambient atmosphere and keep the total pressure of the chamber stable. The pressure range is 10~900Torr;

[0038] 3) Furnace heating up:

[0039] Select an appropriate temperature gradient (1-20°C / min) to raise the temperature and ...

Embodiment 2

[0048] Embodiment two graphite furnace growth AlN single crystal (using methane or acetylene)

[0049] 1) Furnace charging and ventilation:

[0050] Place the tantalum carbide crucible with AlN sintered body on the graphite furnace body and close the furnace body, vacuumize the furnace body environment to 1 Torr, and fill the high-purity nitrogen gas to 500 Torr, and replace the atmosphere in the chamber by filling and pumping for 3 to 5 times, and finally 1 time to vacuum up to 10 -4 Torr;

[0051] 2) The furnace body is inflated and maintained:

[0052] After stopping the vacuuming of the furnace body, feed high-purity nitrogen gas or a mixed gas of high-purity nitrogen gas / high-purity argon gas with a ratio range of 0.1 to 0.9 into the furnace body to form an ambient atmosphere and keep the total pressure of the chamber stable. The pressure range is 10~900Torr;

[0053] 3) Furnace heating up:

[0054] Select an appropriate temperature gradient (1-20°C / min) to raise the...

Embodiment 3

[0063] Embodiment Three tungsten furnace growth AlN single crystal (using ammonia or hydrogen)

[0064] 1) Furnace charging and ventilation:

[0065] Place the tungsten crucible with AlN sintered body on the tungsten furnace body and close the furnace body, vacuumize the furnace body environment to 1 Torr, and fill high-purity nitrogen gas to 500 Torr, and replace the atmosphere in the cavity by filling and pumping for 3 to 5 times, and finally 1 Vacuum up to 10 times - 4 Torr;

[0066] 2) The furnace body is inflated and maintained:

[0067] After stopping the vacuuming of the furnace body, feed high-purity nitrogen gas or a mixed gas of high-purity nitrogen gas / high-purity argon gas with a ratio range of 0.1 to 0.9 into the furnace body to form an ambient atmosphere and keep the total pressure of the chamber stable. The pressure range is 10~900Torr;

[0068] 3) Furnace heating up:

[0069] Select an appropriate temperature gradient (1-20°C / min) to raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com