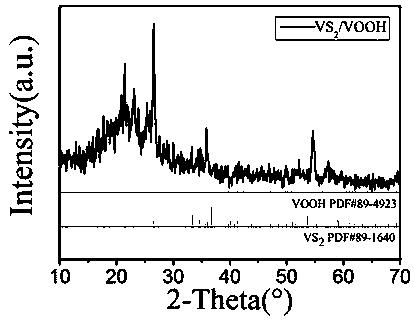

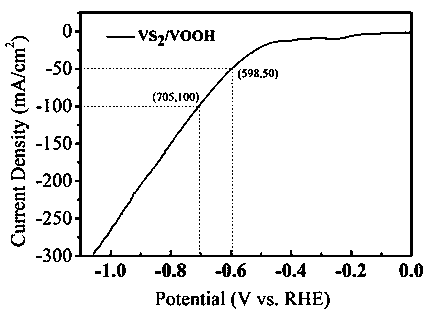

Nanometer floriform vanadium disulfide/hydroxy vanadium oxide difunctional composite electrocatalyst and preparation method thereof

A vanadium disulfide, hydroxyl oxidation technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of electrochemical application limitations, high cost, etc., and achieve a simple synthesis route, low synthesis Uniform effect of temperature and chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Soak the graphite paper in pure acetone solution for 5 minutes, then immerse the graphite paper in 3mol / L hydrochloric acid for 5 minutes, and finally wash it with ethanol and deionized water alternately for 3 times, vacuum at 25°C Obtain the treated graphite paper after drying for 15h;

[0021] (2) Weigh NH 4 VO 3 and C 2 h 5 Add NS to 20ml deionized water at the same time to control NH 4 VO 3 :C 2 h 5 The molar ratio of NS is 1:10, and 1ml of ammonia water is added. At this time, the concentration of the vanadium source is 0.05mol / L, and the concentration of the sulfur source is 0.5mol / L. Stir magnetically at room temperature for 30min to obtain a clear solution A;

[0022] (3) Put the graphite paper processed in step (1) into the reaction liner, then pour solution A into the reaction liner and seal it, then install the liner in the outer kettle and fix it in a homogeneous reactor , then reacted at 160°C for 18h;

[0023] (4) After the hydrothermal reacti...

Embodiment 2

[0025] (1) Soak the graphite paper in pure acetone solution for 10 minutes, then immerse the graphite paper in 2mol / L hydrochloric acid for 10 minutes, and finally rinse it with ethanol and deionized water for 4 times, and vacuum at 35°C Obtain the treated graphite paper after drying for 14h;

[0026] (2) Weigh NH 4 VO 3 and C 2 h 5 Add NS to 25ml deionized water at the same time to control NH 4 VO 3 :C 2 h 5 The molar ratio of NS is 1:6, and 2ml of ammonia water is added. At this time, the concentration of the vanadium source is 0.08mol / L, and the concentration of the sulfur source is 0.48mol / L. Stir magnetically at room temperature for 40min to obtain a clear solution A;

[0027] (3) Put the graphite paper processed in step (1) into the reaction liner, then pour solution A into the reaction liner and seal it, then install the liner in the outer kettle and fix it in a homogeneous reactor , then reacted at 180°C for 20h;

[0028] (4) After the hydrothermal reaction is...

Embodiment 3

[0030] (1) Soak the graphite paper in pure acetone solution for 15 minutes, then immerse the graphite paper in 4mol / L hydrochloric acid for 10 minutes, and finally wash it with ethanol and deionized water alternately for 3 times, vacuum at 40°C Obtain the treated graphite paper after drying for 12h;

[0031] (2) Weigh NH 4 VO 3 and C 2 h 5 Add NS to 30ml deionized water at the same time to control NH 4 VO 3 :C 2 h 5 The molar ratio of NS is 3:14, and 3ml of ammonia water is added. At this time, the concentration of the vanadium source is 0.1mol / L, and the concentration of the sulfur source is 0.467mol / L. Stir magnetically at room temperature for 45min to obtain a clear solution A;

[0032] (3) Put the graphite paper processed in step (1) into the reaction liner, then pour solution A into the reaction liner and seal it, then install the liner in the outer kettle and fix it in a homogeneous reactor , then reacted at 180°C for 22h;

[0033] (4) After the hydrothermal rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com