Nanometer composite coating and preparation method thereof

A nano-composite and coating technology, applied in the field of nano-composite coatings and their preparation, can solve the problems of unsatisfactory formaldehyde elimination effect of air purification coatings, incompatibility between photoinitiators and resin systems, and difficulty in controlling the dosage. , to achieve the effect of improving catalytic oxidation of formaldehyde, improving self-cleaning performance, and expanding layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

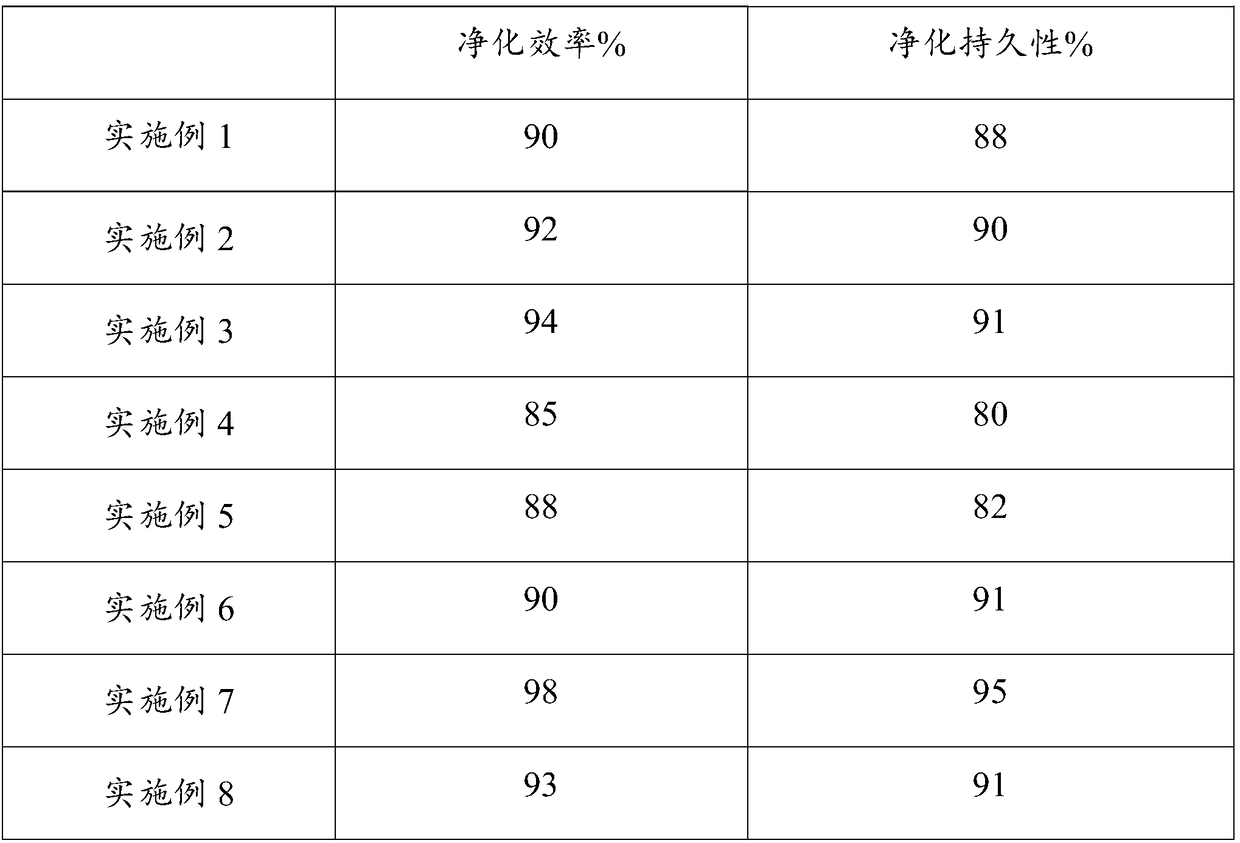

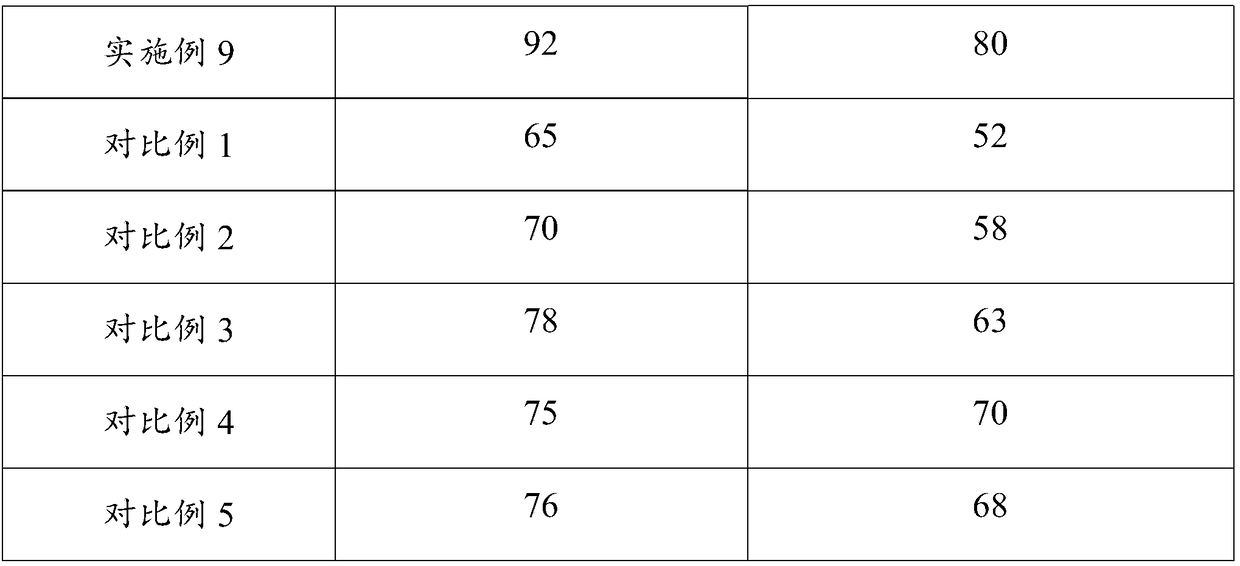

Examples

Embodiment 1

[0025] The nanocomposite material of this embodiment includes the following components by weight: 50 parts of composite nano diatomite, 30 parts of composite photocatalyst, 8 parts of polyphenylene sulfone resin, 5 parts of cross-linked alcoholamine cellulose, hydrogen oxide 6 parts of aluminum, 4 parts of dimethyl tin laurate.

[0026] The nanocomposite material of the present embodiment is prepared by the following method:

[0027] Step 1: Mix the composite nano diatomite, composite photocatalyst and aluminum hydroxide into a magnetic stirrer and stir for 3 hours, then disperse with ultrasonic waves for 50 minutes to obtain a mixture A;

[0028] Step 2: Add polyphenylene sulfone resin, cross-linked alkanolamine cellulose and deionized water to a magnetic stirrer, heat in a water bath to 65°C, stir and mix for 60 minutes to obtain a mixed solution B;

[0029] Step 3: Add the mixed solution B and dimethyl tin laurate to the mixed solution A in sequence, stir magnetically for ...

Embodiment 2

[0041] The only difference between this implementation and Example 1 is that the mass ratio of library clay and diatomite in the composite nano-diatomite is Faku clay: diatomite=1:3; the mass ratio of composite photocatalyst titanium dioxide and antimony trioxide Titanium dioxide: antimony trioxide = 3:6

Embodiment 3

[0043] The only difference between this implementation and Example 1 is that the mass ratio of library clay and diatomite in the composite nano-diatomite is Faku clay: diatomite=1:5; the mass ratio of composite photocatalyst titanium dioxide and antimony trioxide Titanium dioxide: antimony trioxide = 3:7

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap