Low-concentration sodium-salt-containing organic waste liquid incinerator, incineration system and incineration process

An organic waste liquid, incinerator technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of shortening equipment operation period, reducing equipment economy, reducing heat exchange efficiency, etc., to extend equipment inspection and maintenance period, Improved economy, reduced load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

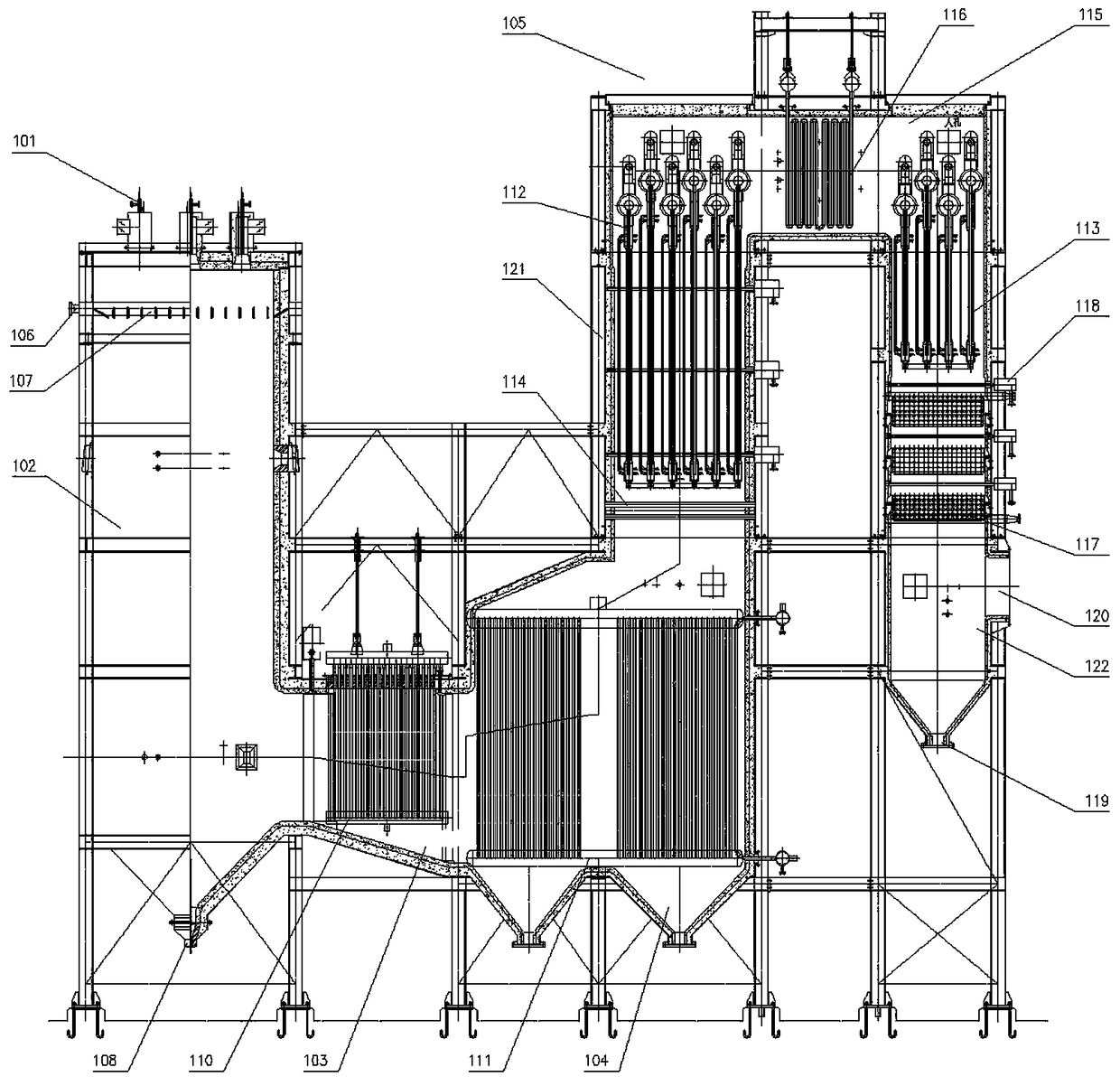

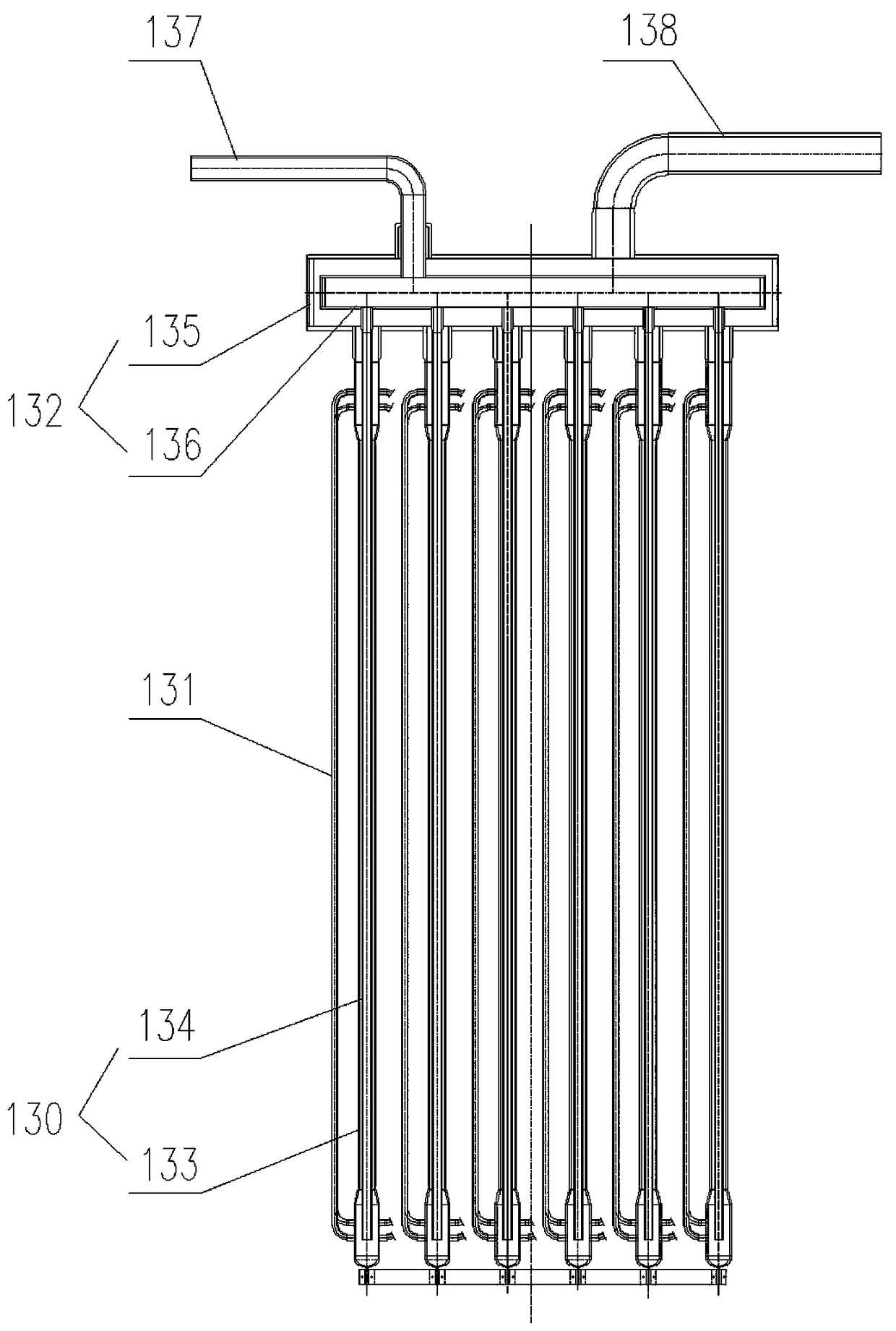

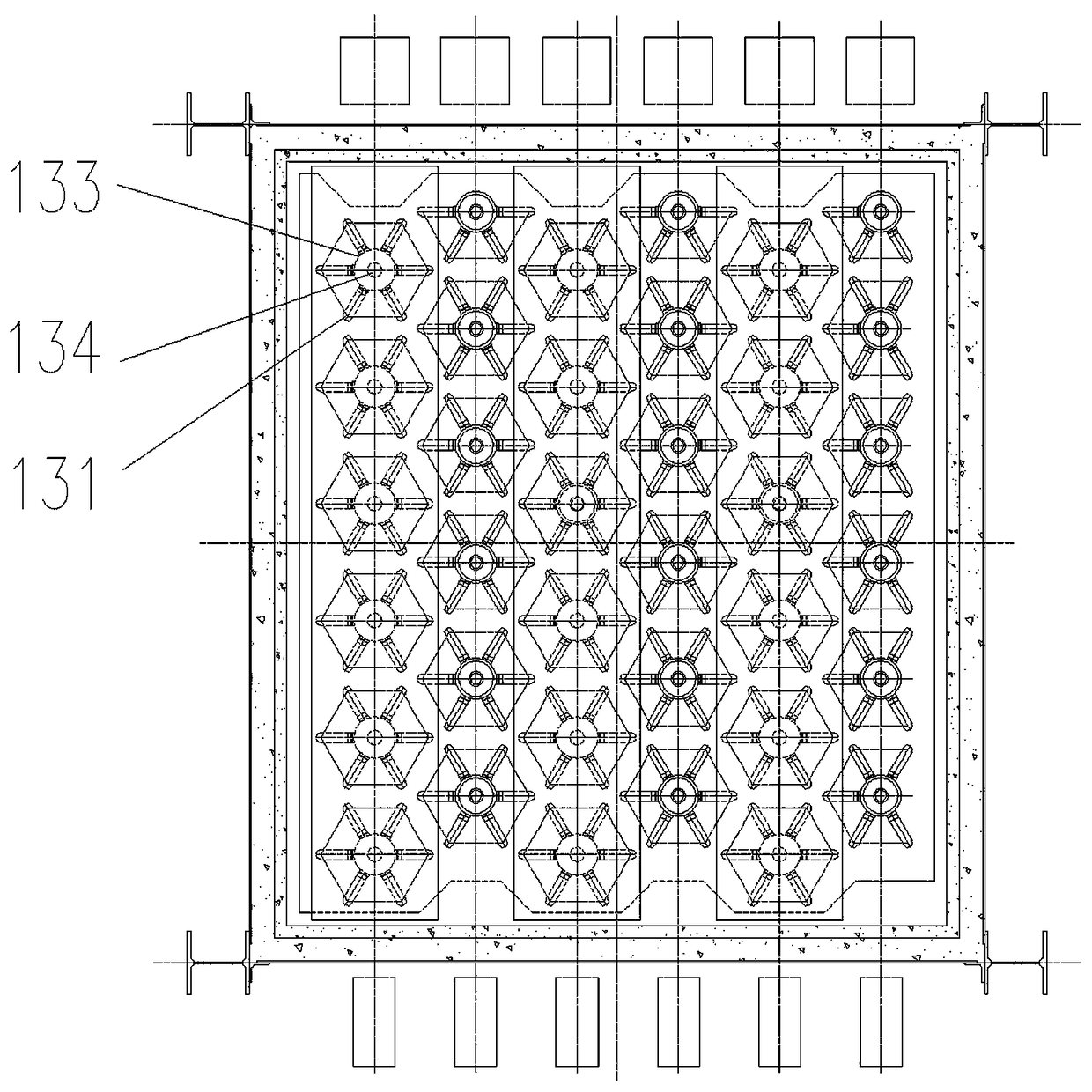

[0042] like figure 1 As shown, a low-concentration sodium-salt-containing organic waste liquid incinerator 1 includes a burner 101, a vertical top-burning incineration chamber 102, a first transition section 103, a gas-solid separation settling chamber 104, and a Π-shaped convection chamber 105. The burner 101 is arranged on the top of the incineration chamber 102, the upper side of the incineration chamber 102 is provided with an inlet 106 for organic waste liquid and water vapor, and an organic waste liquid and water vapor distributor 107 is arranged at a corresponding place in the incineration chamber 102, which is located below the burner 101 , the bottom of the incineration chamber 102 is provided with a funnel-shaped molten slag outlet 108, the Π-shaped convection chamber 105 includes a first convection section 121, a second transition section 115, and a second convection section 122, and the settling chamber 104 One foot of said Π-shaped convection chamber 105, that is,...

Embodiment 2

[0049] like Figure 4 As shown, a low-concentration sodium-containing organic liquid incineration system includes an incinerator 1, a waste liquid pump 2, a vaporizer 3, an electrostatic precipitator 4, an induced draft fan 5, a chimney 6 and a steam drum 7, and the incinerator 1 passes through The incineration flue gas outlet 120 is sequentially connected with the electrostatic precipitator 4, the induced draft fan 5 and the chimney 6;

[0050] The gasifier 3 includes an organic waste liquid inlet, an organic waste liquid outlet, and an organic waste gas outlet. The organic waste liquid outlet is connected to the organic waste liquid and water vapor inlet 106 of the incinerator 1, and the organic waste gas outlet is connected to the waste liquid pump 2 to connect to the incinerator. 1 burner 101;

[0051] Described steam drum 7 is arranged on the top of incinerator 1, and its riser pipe, downcomer connect the first evaporator 110 in the incinerator 1, the second evaporator 1...

Embodiment 3

[0055] A low-concentration sodium-salt-containing organic waste liquid incineration process utilizes the incineration system described in Embodiment 2, and its steps include:

[0056] ① The system is equipped with an induced draft fan, which operates under slight negative pressure;

[0057] ② Supplementary fuel enters from the burner 101 and burns in the incinerator 102, which is used to heat up the incinerator 1 when it is started and to ensure safe production and provide auxiliary heat during normal operation;

[0058] ③ Low-concentration sodium-salt-containing organic waste liquid enters the gasifier 3 and is gasified by superheated steam generated by incineration flue gas;

[0059] ④ The saturated water vapor and light component organic waste liquid gas generated in the gasifier 3 are evenly distributed into the incineration chamber 102 which has reached the incineration temperature with a slight negative pressure and incinerated;

[0060] ⑤The organic waste liquid concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com