Method for preparing penaeus vannamei formula feed capable of improving survival rate

A technology of compound feed and white shrimp, which is applied in the field of feed, can solve problems such as less attention to the health of the hepatopancreas, and achieve the effects of reducing the burden on the liver, improving utilization, and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

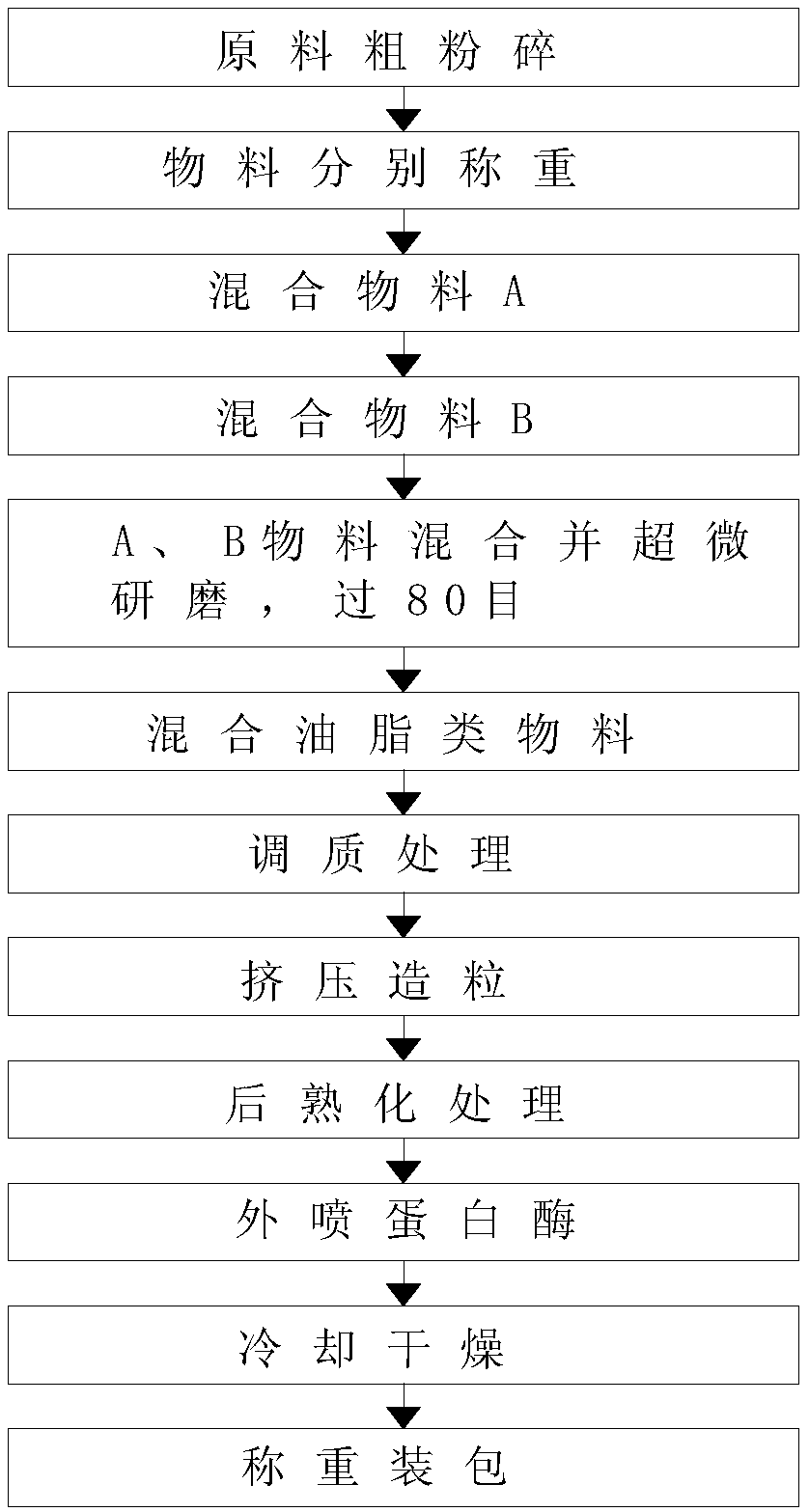

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] see as figure 1 As shown, the raw material weight ratio components of the Penaeus vannamei compound feed described in this specific embodiment are: 20 parts of high-gluten flour, 10 parts of peeled and expanded soybean meal, 6 parts of bio-fermented feed, 30 parts of imported steam fish meal, krill meal 5 parts, 2 parts of phospholipid oil, 1 part of soybean oil, 1 part of deep-sea fish oil, 0.2 parts of choline chloride with 60% content, 2.0 parts of calcium dihydrogen phosphate, 0.3 parts of table salt, 0.5 parts of yeast hydrolyzate, 0.02 parts of antibacterial peptide, slow Release-coated methionine 0.3 part, Gandankang 0.3 part, shrimp special premix 0.8 part; said shrimp special premix: the content of feed components per 1000g is as follows: Vitamin A 1.3 million IU, vitamin D3 270,000 IU , vitamin E 13000mg, vitamin K3 4500mg, vitamin B1 3000mg, vitamin ...

specific Embodiment approach 2

[0044] The difference between this specific embodiment and specific embodiment 1 is that the raw material weight ratio components of the Penaeus vannamei compound feed are: 25 parts of high-gluten flour, 15 parts of peeled and expanded soybean meal, 10 parts of biological fermentation feed, imported steam 25 parts of fish meal, 8 parts of krill meal, 3 parts of phospholipid oil, 2 parts of soybean oil, 1-2 parts of deep sea fish oil, 0.2 part of choline chloride with 60% content, 2.0 part of calcium dihydrogen phosphate, 0.3 part of table salt, yeast hydrolyzate 0.5 parts, 0.03 parts of antimicrobial peptides, 0.3 parts of sustained-release coated methionine, 0.5 parts of Gandankang, and 1.2 parts of shrimp special premix. Other components and the preparation method are the same as those in Embodiment 1.

specific Embodiment approach 3

[0045] The difference between this specific embodiment and specific embodiment 1 is that the raw material weight ratio components of the Penaeus vannamei compound feed are: 23 parts of high-gluten flour, 13 parts of peeled and expanded soybean meal, 7 parts of bio-fermented feed, imported steam 27 parts of fish meal, 7 parts of krill meal, 2.5 parts of phospholipid oil, 1.5 parts of soybean oil, 1.5 parts of deep sea fish oil, 0.2 part of choline chloride with 60% content, 1.8 parts of calcium dihydrogen phosphate, 0.3 part of table salt, 0.5 part of yeast hydrolyzate , 0.025 parts of antimicrobial peptides, 0.25 parts of sustained-release coated methionine, 0.4 parts of Gandankang, and 0.95 parts of shrimp special premix. Other components and the preparation method are the same as those in Embodiment 1.

[0046] The bio-fermented feed described in the above specific embodiments can use a high-efficiency bio-fermented feed with the patent number 201610789853.7.

[0047] The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com