UCNPs @ MIL-53 nano composite material and preparation method thereof

A nanocomposite material, MIL-53 technology, applied in the design and preparation of UCNPs@MIL-53 nanocomposite materials, can solve the problems of poor biodistribution, poor pharmacokinetics, adverse side effects, etc., and achieve tissue penetration depth Deep, low biotoxicity, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

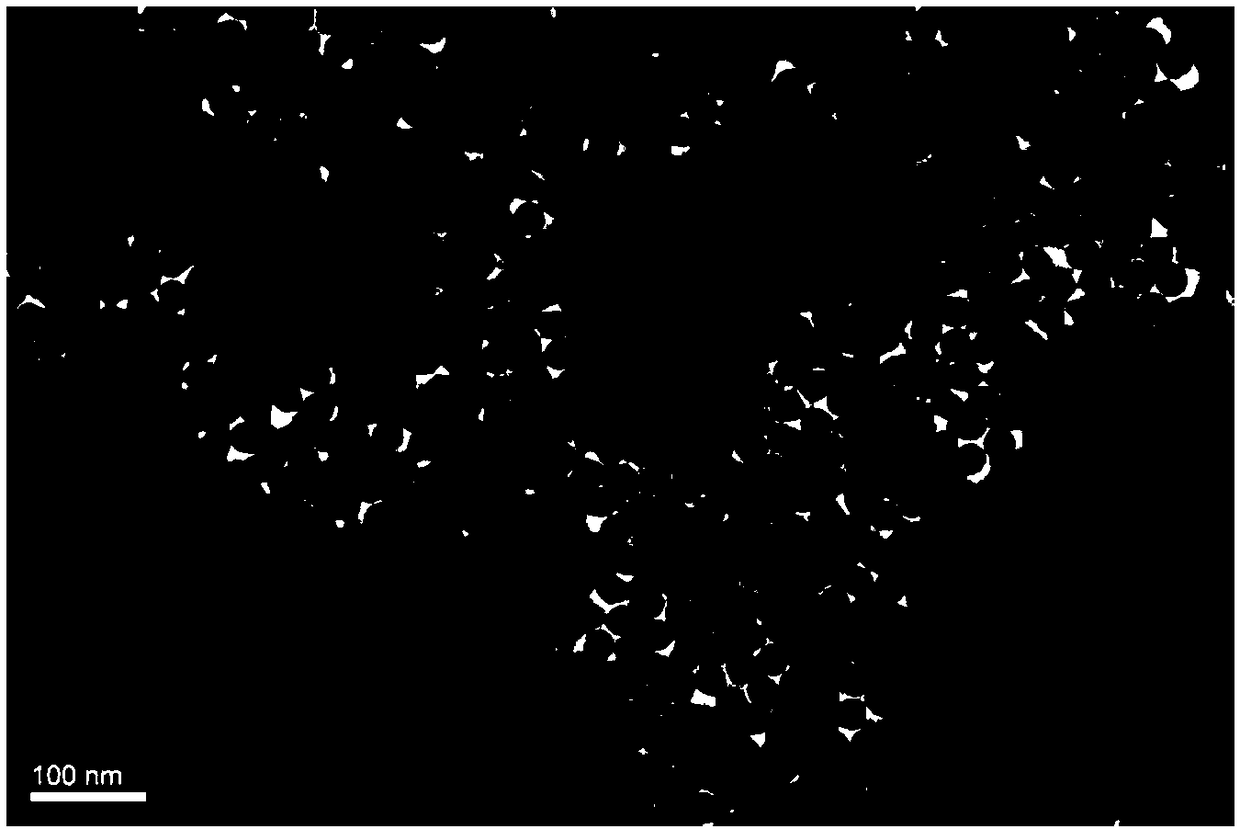

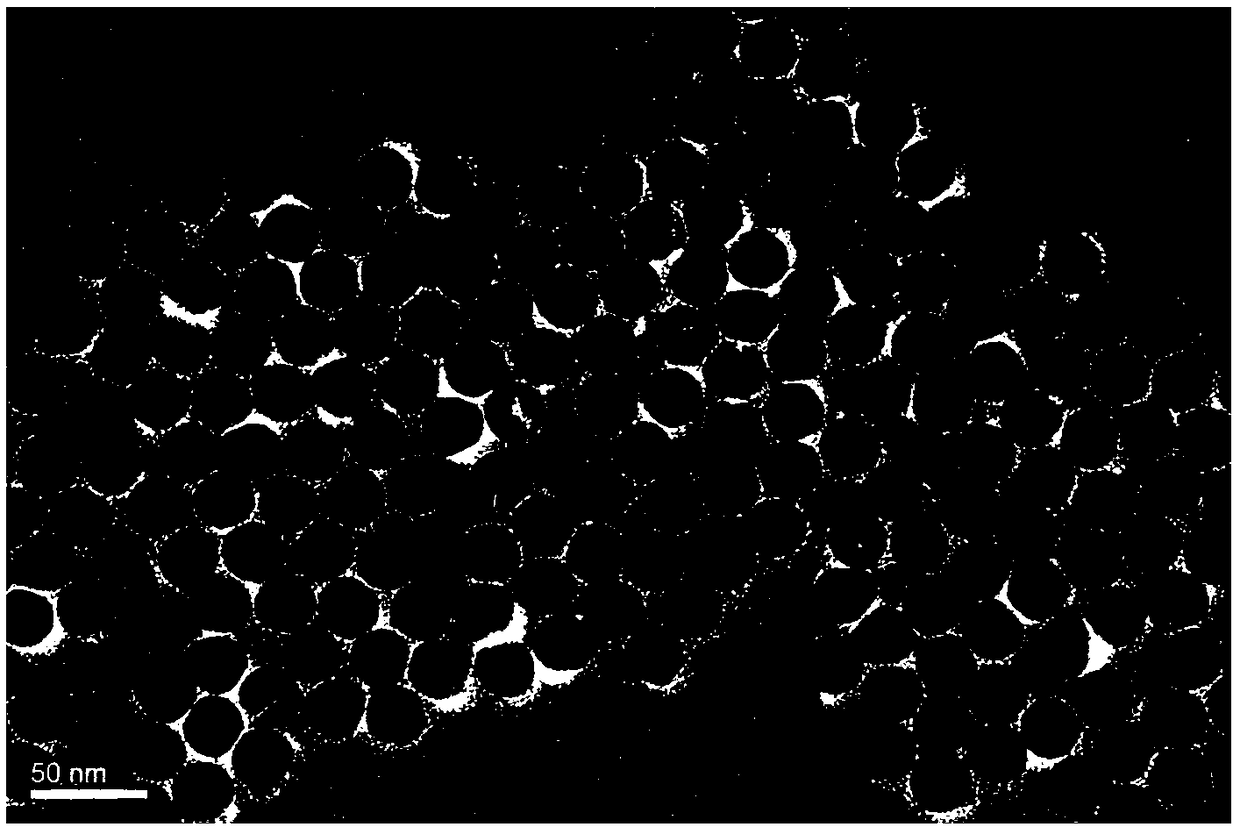

[0049] A preparation method of said UCNPs@MIL-53 (i.e. MIL-53 coated UCNPs) nanocomposite material, which comprises the following steps:

[0050] Step S1, preparing mother core particles

[0051] Ln(CH 3 COO) 3 (Ln=Y, Yb, Er, molar ratio Y:Yb:Er=78%:20%:2%) was dissolved in water, added oleic acid, and removed moisture in an inert atmosphere, then added 1-octadecene, Cool to room temperature, respectively add 1 mol / L sodium hydroxide and 0.4 mol / L ammonium fluoride methanol mixed solution, stir at room temperature for more than 2 hours, and obtain the mother nucleus solution;

[0052] Step S2, UCNPs nanoparticle crystallization growth

[0053] Dehydrate and remove methanol from the mother nucleus solution in the above step S1 in a high vacuum environment, specifically, vacuum once at room temperature until the solution has no bubbles, then heat up to 120°C to remove water and methanol that has not been removed in a vacuum until Until the solution has no bubbles, the vacuum...

Embodiment 1

[0073] (1) 4mmol of Ln(CH 3 COO) 3 (Ln=Y, Yb, Er where Y:Yb:Er=78%:20%:2%) was dissolved in 20ml of water, added 24ml of oleic acid, heated to 150°C-170°C with argon, kept for 30min, and stopped After heating, add 64ml of 1-octadecene, cool to room temperature, add 10ml of 1mol / L sodium hydroxide and 40ml of 0.4mol / L-ammonium fluoride in methanol, and stir for 2 hours at room temperature.

[0074] (2) Vacuumize the solution in the above (1) step to remove methanol for 0.5h, then raise the temperature to 120°C to remove water and remove methanol for 1h, stop vacuuming, heat up to 280°C±2°C with argon gas, keep it for 75min, and cool to At room temperature, ethanol was added for precipitation.

[0075] (3) Centrifuge the solution of the above (2) step at 11000rpm for 10min to collect the product, and wash it 3 times with a mixed solution of cyclohexane: ethanol = 1:1, and finally the obtained NaYF 4 : Yb, Er dispersed in 20ml chloroform.

[0076] (4) Disperse 150 mg of NaYF4...

Embodiment 2

[0080] (1) 4mmol of Ln(CH 3 COO) 3 (Ln=Y, Yb, Er where Y:Yb:Er=78%:20%:2%) was dissolved in 20ml of water, added 24ml of oleic acid, heated to 150°C-170°C with argon, kept for 30min, and stopped After heating, add 64ml of 1-octadecene, cool to room temperature, add 10ml of 1mol / L sodium hydroxide and 40ml of 0.4mol / L ammonium fluoride in methanol, and stir for 2 hours at room temperature.

[0081] (2) Vacuumize the solution in the above (1) step to remove methanol for 0.5h, then raise the temperature to 120°C to remove water and remove methanol for 1h, stop vacuuming, heat up to 300°C±2°C with argon gas, keep it for 75min, and cool to At room temperature, ethanol was added for precipitation.

[0082] (3) Centrifuge the solution of the above (2) step at 11000rpm for 10min to collect the product, and wash it 3 times with a mixed solution of cyclohexane: ethanol = 1:1, and finally the obtained NaYF 4 : Yb, Er dispersed in 30ml chloroform.

[0083] (4) Disperse 150 mg of NaYF4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com