MOF (metal organic framework) modified nanofiltration/reverse osmosis membrane and application thereof

A metal-organic framework and reverse osmosis membrane technology, applied in reverse osmosis, semi-permeable membrane separation, permeation/dialysis water/sewage treatment, etc., can solve the problem of uneven dispersion of metal-organic framework materials, waste of metal-organic framework materials, and limited membrane Performance and other issues, to achieve the effect of easy operation, simple method and retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

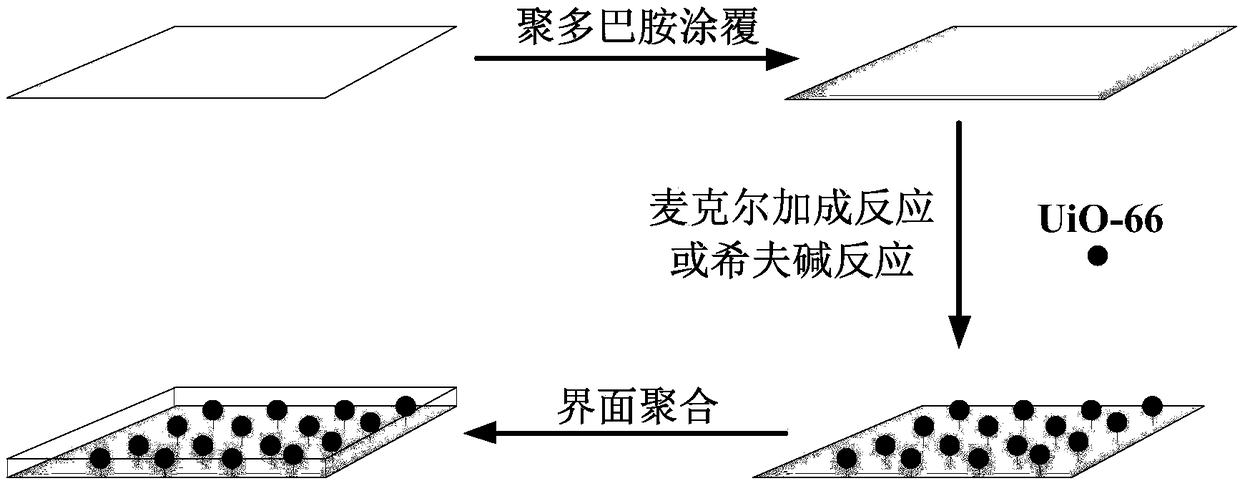

[0027] Example 1 Preparation of UiO-66 / TFN Nanofiltration Membrane

[0028] (1) Add 3.87g of polyvinylidene fluoride into 20mL of N,N-dimethylformamide, stir to dissolve, let it stand for defoaming, and form a stable and uniform casting solution. Use a spatula to scrape and coat the casting solution on a glass plate, and quickly put it into a deionized water coagulation bath. After the phase inversion is complete, transfer the polyvinylidene fluoride support layer to new deionized water to continue solvent exchange for 24 hours.

[0029] (2) ZrCl 2 (0.105g) and terephthalic acid (0.105g) were added to the N,N-dimethylformamide / acetic acid mixture (the volumes were 75mL and 5mL respectively), stirred and dissolved, and reacted at 100°C for 36h, After cooling to room temperature, stir in methanol at 80°C for 24 hours, centrifuge and dry to obtain UiO-66 crystals.

[0030] (3) Immerse the polyvinylidene fluoride support layer in 100mL Tris-HCl (pH=7.0) buffer solution containin...

Embodiment 2

[0033] Embodiment 2 prepares UiO-66 / TFN reverse osmosis membrane

[0034](1) Add 2.28g of polyimide into 20mL of N-methylpyrrolidone, stir to dissolve and defoam after standing to form a stable and uniform casting solution. Use a scraper to scrape the casting liquid onto the glass plate, and then quickly put it into the deionized water coagulation bath. After the phase inversion is complete, transfer the polysulfone support layer to new deionized water to continue the solvent exchange for 12 hours.

[0035] (2) ZrCl 2 (0.105g) and terephthalic acid (0.105g) were added to the N,N-dimethylformamide / acetic acid mixture (the volumes were 75mL and 5mL respectively), stirred and dissolved, and reacted at 100°C for 36h, After cooling to room temperature, it was stirred in methanol at 80°C for 24 h, and dried after ionization to obtain UiO-66 crystals.

[0036] (3) Immerse the polyimide support layer in 100mL Tris-HCl (pH=7.0) buffer solution containing 0.1g catechol, shake and reac...

Embodiment 3

[0039] Embodiment 3 prepares IRMOF-3 / TFN nanofiltration membrane

[0040] (1) Add 8.09g of polyvinylidene fluoride into 20mL of N,N-dimethylformamide, stir to dissolve, and let it stand for defoaming to form a stable and uniform casting solution. Use a spatula to scrape and coat the casting solution on a glass plate, and quickly put it into a deionized water coagulation bath. After the phase inversion is complete, transfer the polyvinylidene fluoride support layer to new deionized water to continue solvent exchange for 48 hours.

[0041] (2) Zn(NO 3 ) 2 ·6H 2 O (0.4462g) and 2-aminoterephthalic acid (0.0906g) were added to N,N-dimethylformamide (50mL), stirred and dissolved, reacted at 100°C for 24h, cooled to room temperature, and used N,N-dimethylformamide and dichloromethane were washed alternately, and then dried in vacuum at 60°C to obtain IRMOF-3 crystals.

[0042] (3) Immerse the polyvinylidene fluoride support layer in 100mL Tris-HCl (pH=7.0) buffer solution contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com