Preparation method of bismuth doped tin oxide/bismuth phosphate composite photocatalyst

A technology of tin oxide and bismuth phosphate, which is applied in the synthesis field of composite photocatalytic materials, can solve the problems of high photogenerated electron-hole recombination rate and low photocatalytic efficiency, and achieves wide absorption spectrum range, low cost and good market application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

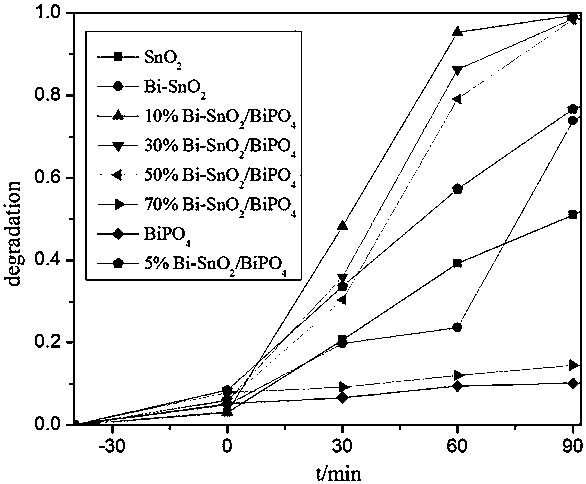

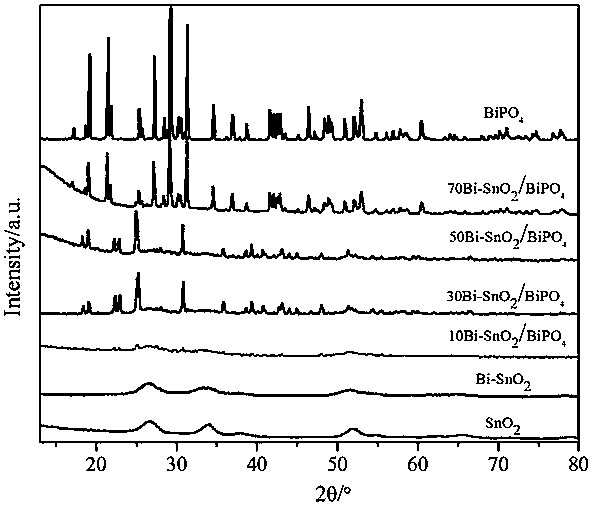

[0011] 0.5694g Na 2 SnO 3 4H 2 O was dissolved in 5 mL of deionized water, and then slowly added dropwise to 15 mL of dilute nitric acid solution with a molar concentration of 1.43 mol / L under vigorous magnetic stirring to obtain a white turbid solution; additional deionized water was added to make the total volume of the solution 30 mL, Continue to stir for 30 minutes, put the solution in a 50mL autoclave, and place it in a constant temperature oven at 180°C for hydrothermal reaction for 24 hours. After the autoclave is cooled to room temperature, centrifuge the reaction solution, and wash it with deionized water until neutral. Then washed with absolute ethanol, and then dried in a constant temperature oven at 60°C for 12 hours to obtain SnO 2 Photocatalyst, the photocatalyst degrades Rhodamine B dye wastewater under simulated sunlight (500W xenon lamp) for 1.5h, and the RhB removal rate is 50.96%.

Embodiment 2

[0013] 1.6007g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 15mL of dilute nitric acid solution with a molar concentration of 1.43mol / L to obtain a clear and transparent solution A; 0.2847g Na 2 SnO 3 4H 2 O was dissolved in 5mL of deionized water, and then slowly added dropwise to solution A under vigorous magnetic stirring to obtain white turbid solution B. Additional deionized water was added to make the total volume of the solution 30mL, and the stirring was continued for 30min, and the solution was filled in 50mL In a high-pressure reactor, put it in a constant temperature oven at 180°C for hydrothermal reaction for 24 hours. After the autoclave is cooled to room temperature, the reaction solution is centrifuged, washed with deionized water until neutral, then washed with absolute ethanol, and then placed Bismuth-doped tin oxide (Bi-SnO 2 ) photocatalyst, the photocatalyst degrades Rhodamine B dye wastewater for 1.5h under simulated sunlight (500W xenon lamp), and the RhB re...

Embodiment 3

[0015] 1.6007g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 15mL of dilute nitric acid solution with a molar concentration of 1.43mol / L to obtain a clear and transparent solution A; 1.1814g Na 2 HPO 4 12H 2 O was dissolved in 5mL deionized water, slowly added dropwise to solution A under magnetic stirring to obtain a white suspension, added deionized water to make the total volume of the solution 30mL, continued to stir for 30min, and filled the solution in a 50mL high-pressure In the reaction kettle, put it in a constant temperature oven at 180°C for hydrothermal reaction for 24 hours. After the autoclave is cooled to room temperature, the reaction liquid is centrifuged, washed with deionized water until neutral, then washed with absolute ethanol, and then placed in 60 BiPO was prepared by drying in a constant temperature drying oven for 12 hours 4 Photocatalyst, the photocatalyst degrades Rhodamine B dye wastewater for 1.5h under simulated sunlight (500W xenon lamp), and the Rh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com