Dry coke quenching residual heat energy recycling and coking wastewater treatment combined technology

A technology for heat energy recovery and coking wastewater, applied in gasification process, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high energy consumption, a large number of external heat sources, and difficult promotion, and achieve high energy value , reduce pollution, improve the effect of coke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

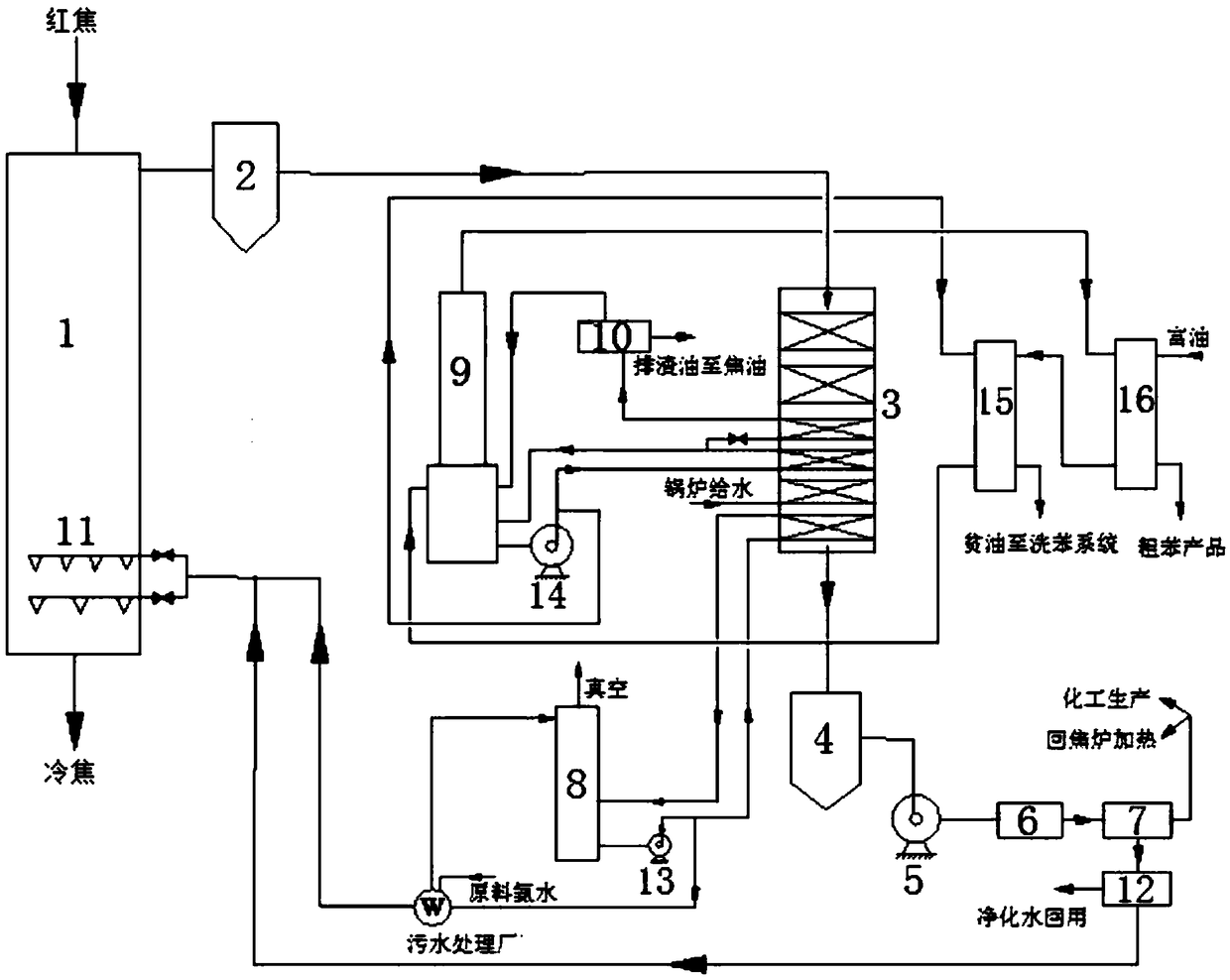

[0043] A combined process of CDQ waste heat recovery and utilization and coking wastewater treatment, using the mixed gas generated after the ammonia distillation wastewater meets red coke vaporization as the cooling gas, and the ammonia distillation wastewater passes through the spray device 11 from the cooling section of the CDQ oven 1 The bottom is ejected upwards, and the temperature rises after absorbing the sensible heat of the red coke during the rising process of the cooling section. The ammonia distillation wastewater directly contacts with the red coke and vaporizes to generate steam, and undergoes an endothermic chemical reaction with the red coke to produce water gas. At the same time, ammonia steam The thermal decomposition gas of organic matter in the wastewater forms a mixed gas with water gas and steam; the mixed gas is discharged from the upper part of the cooling section of the CDQ coke oven 1, that is, the middle annular passage of the CDQ coke oven 1, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com