System for treatment of maleic anhydride sewage and by-production of fuel gas

A fuel gas and sewage technology, applied in biological water/sewage treatment, degassed water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of multi-fuel gas, poor biodegradability, and inability to fully open the loop, etc. Achieve the effect of reducing equipment operating costs and improving biodegradability indicators

Pending Publication Date: 2019-01-18

SHANDONG HUIFENG PETROCHEM GRP CO LTD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, DBP (dibutyl phthalate) is a compound with a benzene ring, and DIBE (diisobutyl hexahydrophthalate) is a compound with a saturated six-membered ring. The sewage can be used for conventional sewage treatment processes. The biochemical properties are poor, and the ring cannot be completely opened. The oily solvents and organic acids in it may cause microbial poisoning to ordinary water treatment microorganisms, and cannot be treated by ordinary anaerobic and aerobic methods.

[0004] If other methods are used to treat maleic anhydride sewage, methods such as electrochemical oxidation and photocatalytic oxidation cannot achieve satisfactory results; if traditional incineration methods are used, more fuel gas will be consumed, which is economically unreasonable; Although the wet oxidation method can achieve a certain effect, the COD content is still high, and the waste gas generated in the process is not easy to handle. The multi-effect evaporation method and air flotation method also produce a lot of solid waste

In other wastewater fields, such as MTO waste lye and high-concentration organic wastewater treatment in the printing and dyeing industry, wet oxidation is generally used for pretreatment, but there will still be waste gas generation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0060] The maleic anhydride sewage discharged from a factory is treated, and the quality of the influent and effluent water is shown in Table 1.

[0061] Table 1

[0062] Water Quality Parameters

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

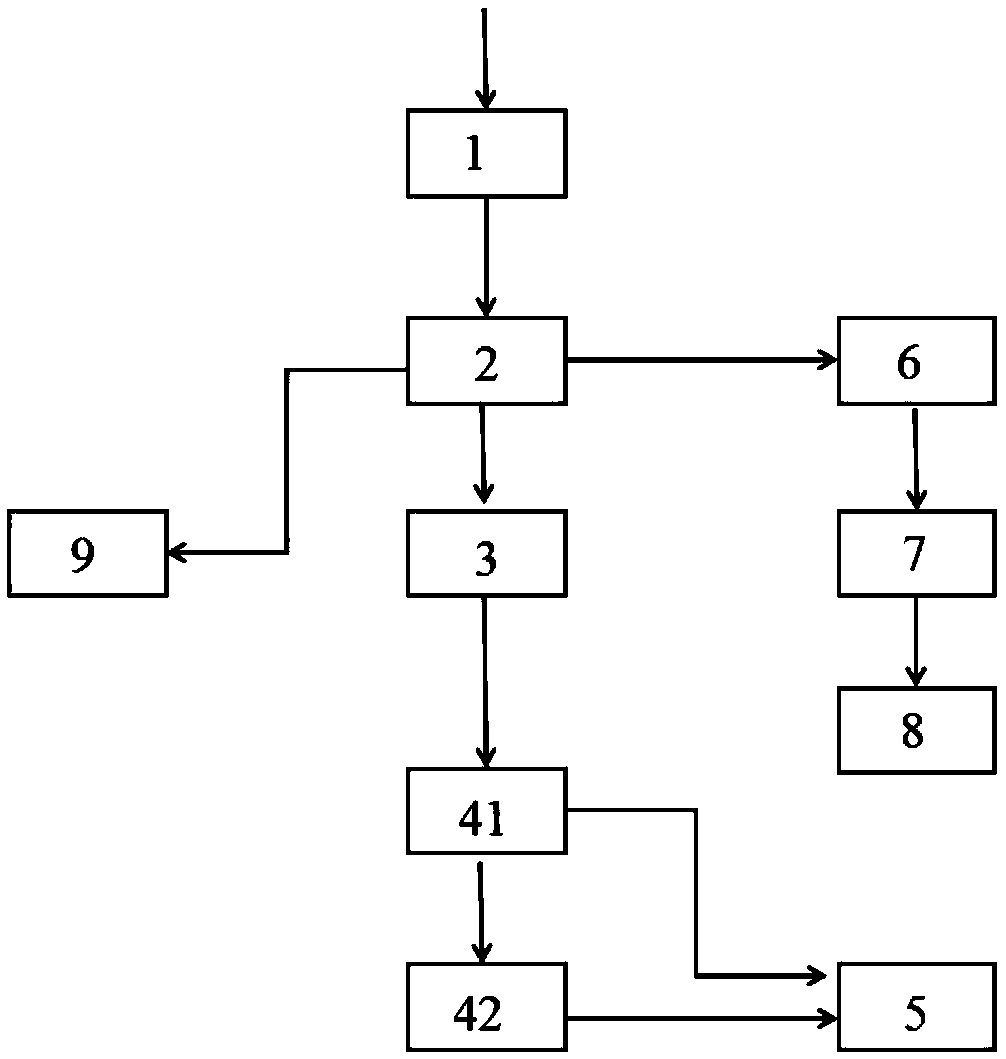

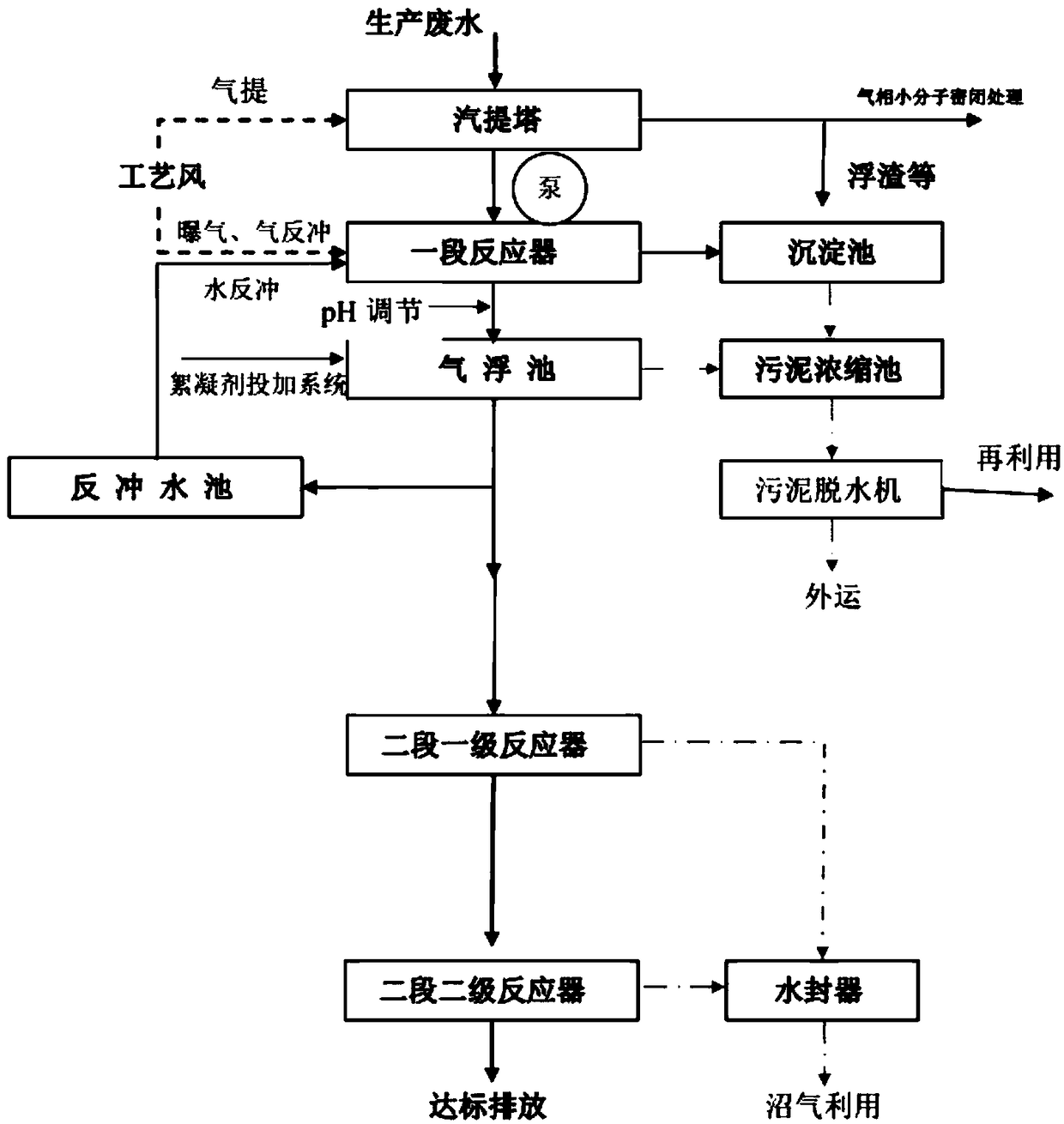

The invention provides a system for treatment of maleic anhydride sewage and by-production of fuel gas. The system comprises a stripping tower, a first reactor, a floatation tank and a second reactorand can perform normal-pressure stripping, microelectrolysis and anaerobic treatment on the maleic anhydride sewage in turn to remove most COD, organic acids and heterocyclic compounds in the maleic anhydride sewage, then the biodegradability index of the sewage is remarkably increased that the sewage reaches the incoming water index for common biochemical treatment and is qualified in environmental protection emission. In the optimal technical scheme of the invention, a sludge recycling system and a water sealing device are also added so as to realize solid collection and biogas recycling.

Description

technical field [0001] The invention relates to the technical field of industrial equipment, in particular to a system for treating maleic anhydride sewage and producing fuel gas by-product, and a method for using the system to treat maleic anhydride sewage. Background technique [0002] Maleic anhydride, also known as maleic anhydride, maleic anhydride, 2,5-furandione, etc., is a colorless needle-like or flaky crystal in the orthorhombic system. Has a strong pungent smell, soluble in ethanol, ether and acetone, insoluble in petroleum ether and carbon tetrachloride. It is mainly used as a raw material for the production of unsaturated polyester resin, alkyd resin, pesticide malathion, high-efficiency and low-toxicity pesticide 4049, and long-acting iodoamine. It is also a comonomer of paint, maleic rosin, polymaleic anhydride, maleic anhydride-styrene copolymer, and can be used as an organic chemical for the production of ink additives, papermaking additives, plasticizers, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F9/14C02F103/36

CPCC02F9/00C02F1/46C02F3/2846C02F2103/36C02F1/20C02F1/24

Inventor 王正收高方军

Owner SHANDONG HUIFENG PETROCHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com