Special fertilizer for artemisia selengensis, preparation method and application thereof

A technology for special fertilizer and Artemisia annua, applied in the field of special fertilizer for Artemisia annua and its preparation, can solve the problems of reduced social and economic benefits of Artemisia annua, lack of scientific fertilization by farmers, serious environmental pollution, etc., so as to be easily accepted and popularized, and overcome the deficiency of trace elements. , Overcome the effect of excessive nitrogen and phosphorus nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a special fertilizer for Artemisia selengensis including biochar. In parts by weight, the biochar is 20-25 parts, preferably 23 parts. The specific surface area of the biochar is preferably 140m 2 / g above. The preparation method of the biochar preferably includes the following steps:

[0031] The carbonized raw material is crushed to obtain carbonized raw material particles that are carbonized at 400-500° C., and after cooling, they are crushed and pulverized through a 1-2 mm sieve to obtain biochar.

[0032] In the present invention, the carbonization raw material is a mixture of crop straw with a mass concentration of 100%, 50% crop straw and 50% crop waste, or 30% crop straw and 30% crop waste. And 40% by mass percentage of livestock and poultry manure composition. The crop stalks include straws such as straw, corn, wheat or rape. The crop waste includes peanut shells, cotton stalks, corn cobs or waste fruit tree trunks and branches. The pul...

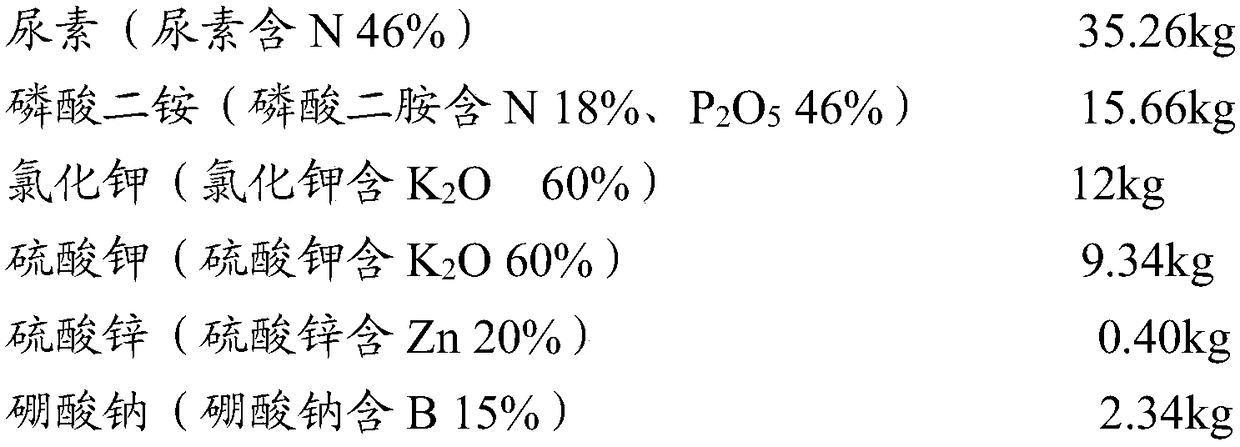

Embodiment 1

[0060]

[0061] The urea, diammonium phosphate, potassium chloride, potassium sulfate, zinc sulfate and sodium borate are mixed and crushed and pulverized through a 1mm sieve. Through extrusion granulation, 2mm irregular granules are made, compressive strength> 6N, to obtain large trace element particles. The large trace element particles are mixed with the biochar, and the mass ratio of the large trace element particles to the biochar is 80:20 to obtain a mixture material.

[0062] Crush the sodium silicate and pass it through a 1mm sieve. Through extrusion granulation, 4mm irregular granules are made, with compressive strength> 6N, the obtained medium element particles are packed into 2kg / bag of medium element particles.

[0063] Pack the mixture into 48kg / bag, add a bag (2kg / bag) of element particles to form 50kg / bag, which is the finished product.

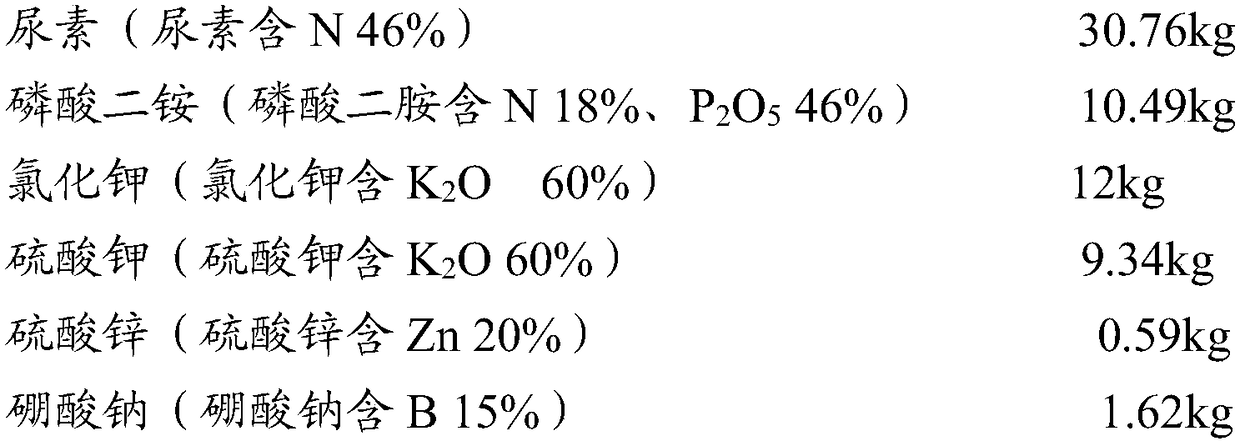

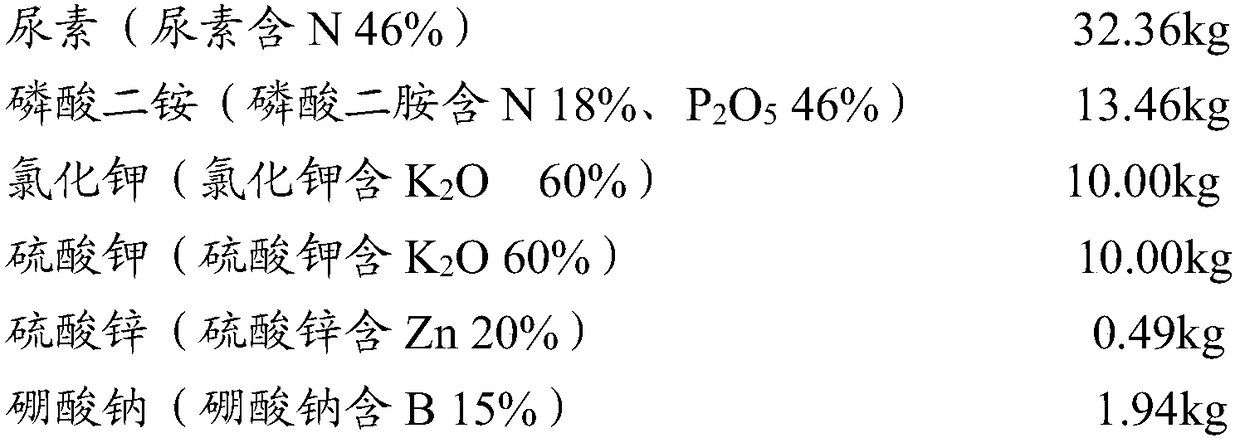

Embodiment 2

[0065]

[0066] Mix urea, diammonium phosphate, potassium chloride, potassium sulfate, zinc sulfate and sodium borate into a 2mm sieve. Through extrusion granulation, 4mm irregular granules are made, with compressive strength> 6N, to obtain large trace element particles. The large trace element particles are mixed with the biochar, and the mass ratio of the large trace element particles to the biochar is 75:25 to obtain a mixture material.

[0067] Crush the sodium silicate and pass it through a 2mm sieve. Through extrusion granulation, 4mm irregular granules are made, with compressive strength> 6N, the obtained medium element particles are packed into 2kg / bag of medium element particles.

[0068] Pack the mixture into 48kg / bag, add a bag (2kg / bag) of element particles to form 50kg / bag, which is the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com