Method for producing levodopa from Mucuna

A technology of levodopa and quinoa beans, applied in the field of levodopa production from quinoa beans, can solve the problems of increased pressure on environmental protection, low extraction rate, short equipment life, etc., to ensure product sales, high product yield, and water consumption little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

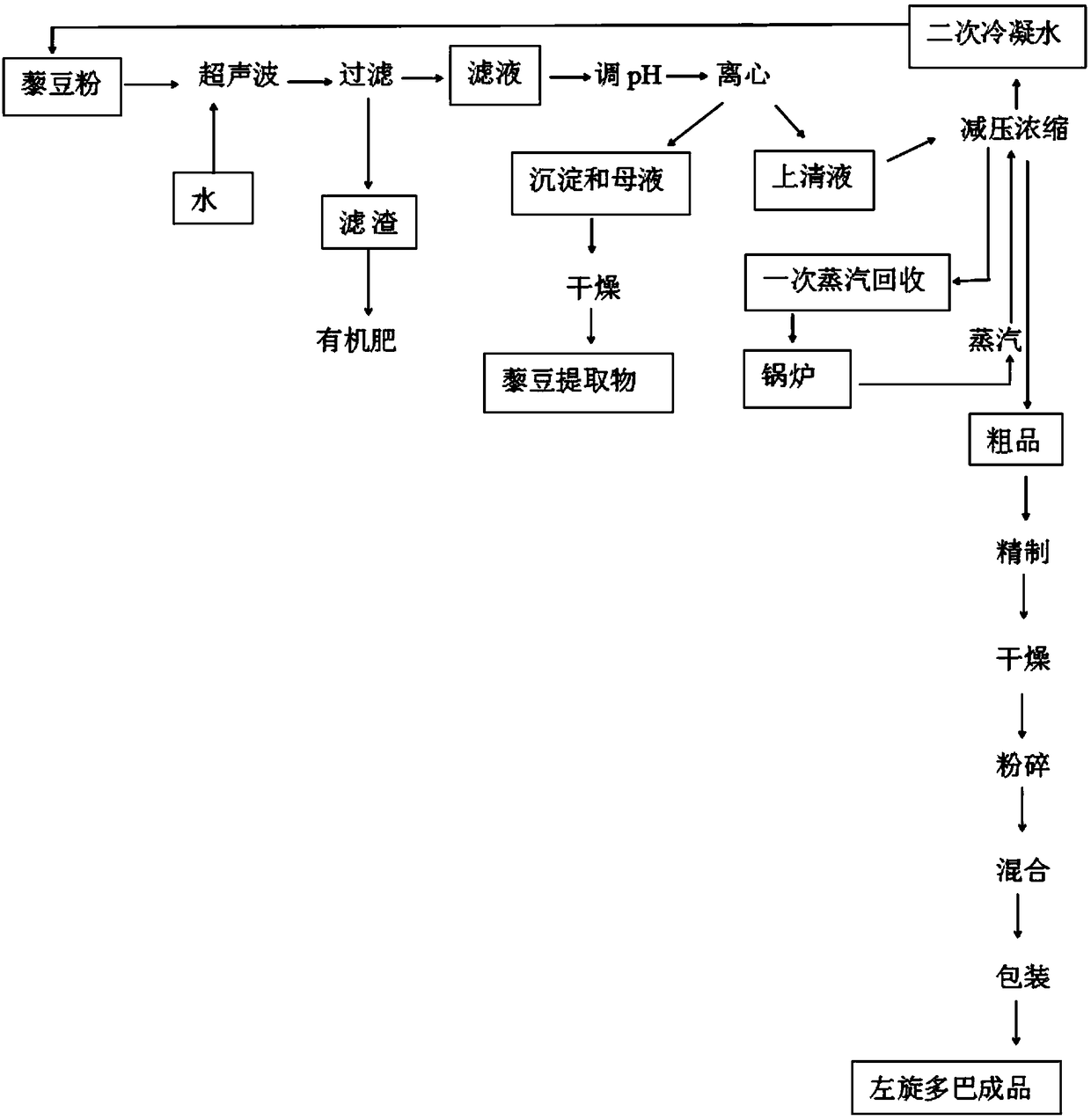

Image

Examples

Embodiment 1

[0031] A method for producing levodopa from quinoa beans, comprising the steps of:

[0032] S1. Treatment of quinoa beans: Clean the quinoa beans, grind them into powder, and pass through an 80-mesh sieve to obtain quinoa bean powder.

[0033] S2, leaching: add vitamin C, acetic acid to dissolve in water, also added table salt simultaneously, the add-on of described table salt is 0.08% of water weight, add quinoa bean powder and mix again, described quinoa bean powder, water, vitamin C. The mass ratio of acetic acid is: quinoa bean flour: water: vitamin C: acetic acid = 1:5:0.005:0.005; ultrasonic extraction is 45min, ultrasonic power is 400W, working temperature is 75°C; then reflux extraction for 8h to complete the first immersion , filter; take the filter residue and carry out the second immersion according to the method of first immersion, and filter; take the filter residue and perform three immersion according to the method of first immersion, wherein the reflux extracti...

Embodiment 2

[0039] A method for producing levodopa from quinoa beans, comprising the steps of:

[0040] S1. Treatment of quinoa beans: Clean the quinoa beans, grind them into powder, and pass through an 80-mesh sieve to obtain quinoa bean powder.

[0041]S2, leaching: add vitamin C, acetic acid into water to dissolve, also added table salt simultaneously, the add-on of described table salt is 0.06% of water weight; C. The mass ratio of acetic acid is: quinoa bean flour: water: vitamin C: acetic acid = 1: 6: 0.005: 0.006; ultrasonic extraction is 40 minutes, ultrasonic power is 450W, working temperature is 75 ° C; then reflux extraction for 9 hours, complete a dip , filter; take the filter residue and carry out the second immersion according to the method of first immersion, and filter; take the filter residue and perform three immersion according to the method of first immersion, wherein the reflux extraction time is changed to 3.5h, filter, and the filter residue is recycled for fermenti...

Embodiment 3

[0047] A method for producing levodopa from quinoa beans, comprising the steps of:

[0048] S1. Treatment of quinoa beans: Clean the quinoa beans, grind them into powder, and pass through an 80-mesh sieve to obtain quinoa bean powder.

[0049] S2, leaching: add vitamin C, acetic acid to dissolve in water, also added table salt simultaneously, the add-on of described table salt is 0.08% of water weight, then add quinoa bean powder and mix, described quinoa bean powder, water, vitamin C. The mass ratio of acetic acid is: quinoa bean flour: water: vitamin C: acetic acid = 1:5:0.004:0.005; ultrasonic extraction is 50min, ultrasonic power is 350W, working temperature is 75°C; then reflux extraction for 8h, complete a dip , filter; take the filter residue and carry out the second immersion according to the method of first immersion, and filter; take the filter residue and perform three immersion according to the method of first immersion, wherein the reflux extraction time is change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com