A diatom mud coating with purifying effect

A technology of diatom mud coating and function, applied in the direction of coating, etc., to achieve the effects of improving photocatalytic performance, improving degradation rate, and increasing catalytic area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

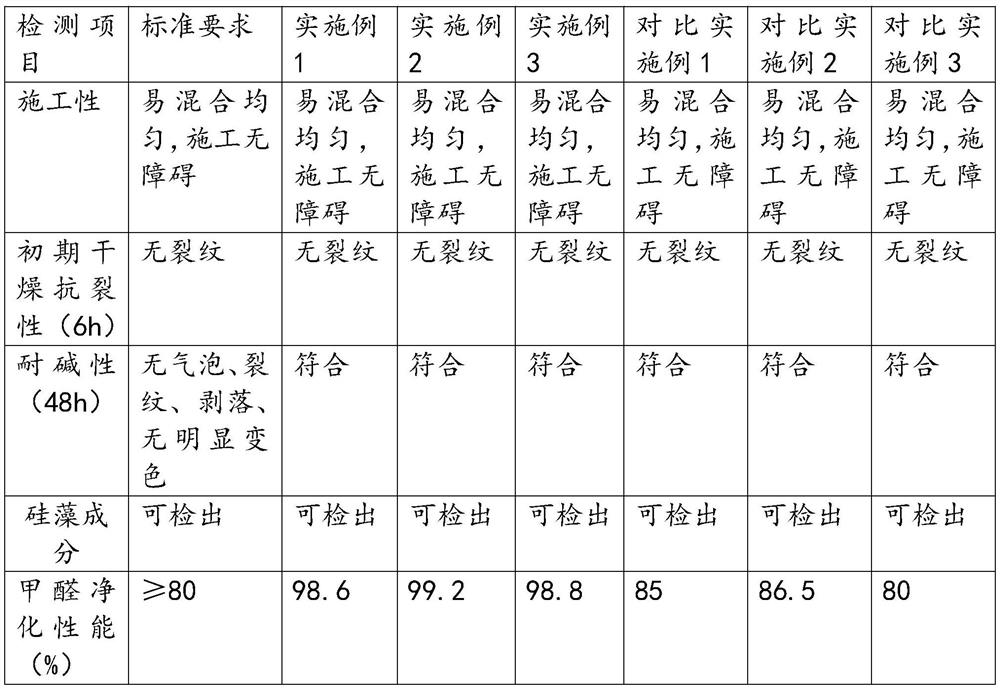

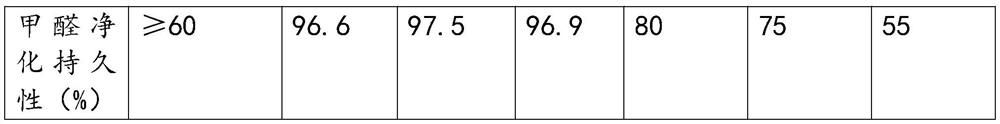

Examples

Embodiment 1

[0037] A kind of diatom mud coating with purifying effect, the weight percent of each raw material is: diatomite 10%, shell powder 5%, light calcium carbonate 25%, ethylene-vinyl acetate copolymer 12%, cellulose ether 5% %, composite photocatalyst 5%, guar gum 6%, surfactant 0.5%, dispersant 1%, the balance is deionized water;

[0038] The composite photocatalyst is Zr-BiNbO 4 Photocatalyst, Zr-BiNbO 4 The preparation method of photocatalyst is:

[0039] (1) 10mol bismuth nitrate is dissolved in 50% concentrated nitric acid, is diluted to 5mol / L by adding water while stirring, obtains bismuth nitrate acid solution after stirring;

[0040] (2) 11mol potassium niobate is dissolved in 5-7mol / L potassium hydroxide solution, after stirring, potassium niobate solution is obtained;

[0041] (3) While stirring the bismuth nitrate solution, drop the potassium niobate solution into it, after the dropwise addition, stir for 15 min;

[0042] (4) 0.1mol zirconium nitrate is added in th...

Embodiment 2

[0051] A kind of diatom mud coating with purifying effect, the weight percent of each raw material is: diatomite 15%, shell powder 3%, light calcium carbonate 30%, ethylene-vinyl acetate copolymer 10%, cellulose ether 7% %, composite photocatalyst 8%, guar gum 9%, surfactant 1, dispersant 2%, and the balance is deionized water;

[0052] The composite photocatalyst is Zr-BiNbO 4 Photocatalyst, Zr-BiNbO 4 The preparation method of photocatalyst is with embodiment 1;

[0053] Described tensio-active agent is fatty alcohol polyoxyethylene ether ammonium sulfate;

[0054] Described dispersant is calcium stearate;

[0055] A kind of preparation method of the diatom ooze coating with purifying effect is:

[0056] S1. Activation of diatomite: Add 1kg of diatomite to a ball mill to grind and pulverize, soak in 10% nitric acid for 5 hours, filter, wash until neutral, dry, and then put it into a muffle furnace for gradient calcination. The calcination steps are: (a) calcine at 300°C...

Embodiment 3

[0060] A diatom mud coating with purifying effect, the weight percentage of each raw material is: diatomite 5%, shell powder 6%, light calcium carbonate 25%, ethylene-vinyl acetate copolymer 12%, cellulose ether 6% %, composite photocatalyst 7%, guar gum 8%, surfactant 0.5%, dispersant 3%, and the balance is deionized water;

[0061] The composite photocatalyst is Zr-BiNbO 4 Photocatalyst, Zr-BiNbO 4 The preparation method of photocatalyst is with embodiment 1;

[0062] Described tensio-active agent is fatty alcohol polyoxyethylene ether ammonium sulfate;

[0063] Described dispersant is calcium stearate;

[0064] A kind of preparation method of the diatom ooze coating with purifying effect is:

[0065] S1. Activation of diatomite: Add 1kg of diatomite into a ball mill to grind and pulverize, soak in 10% nitric acid for 4 hours, filter, wash until neutral, dry, and then put it into a muffle furnace for gradient calcination. The calcination steps are: (a) calcine at 300°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com