Preparation method of high-adhesive-force ultraviolet-proof and anti-pollution flashover coating

An anti-fouling flashover coating and anti-ultraviolet technology, which is applied in coatings and other directions, can solve the problems of short anti-fouling flashover life, anti-fouling flashover coating peeling, peeling, low adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

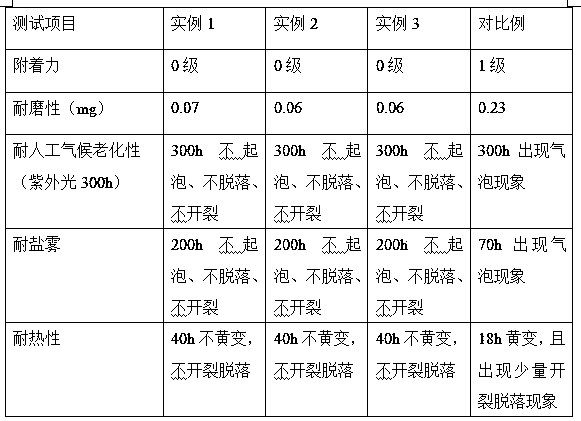

Examples

Embodiment Construction

[0023] Weigh montmorillonite and put it into a pulverizer to pulverize for 30-40 minutes to obtain a pulverized product, mix the pulverized product and titanium dioxide according to a mass ratio of 2:1, put it into a mixer, and stir for 20-30 minutes to obtain a modified substrate; Wash the aloe, put it into a tissue grinder and grind it for 20-30 minutes to obtain the aloe powder, mix the aloe powder with the above-mentioned modified substrate at a mass ratio of 1:3 to obtain a fermentation substrate, and put it into a fermentation tank , then add grape skins with 5% of the mass of the fermentation substrate in the fermenter, and seal and ferment for 4 to 5 days at a temperature of 30 to 40°C to obtain the fermentation product for subsequent use; ︰4 green algae and methanol solution with a mass fraction of 30% are evenly mixed and poured into a water bath. Under the condition of a temperature of 50-60°C, the water bath is heated for 3-4 hours to obtain a water-bath heating obj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com