Anaerobic adhesive for photovoltaic resin board cutting and preparation method and application thereof

A technology of anaerobic adhesive and resin board, applied in the field of anaerobic adhesive, can solve the problem of easily increasing the loss rate of crystalline silicon wafers, and achieve the effects of good curing strength, fast degumming speed and stable storage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

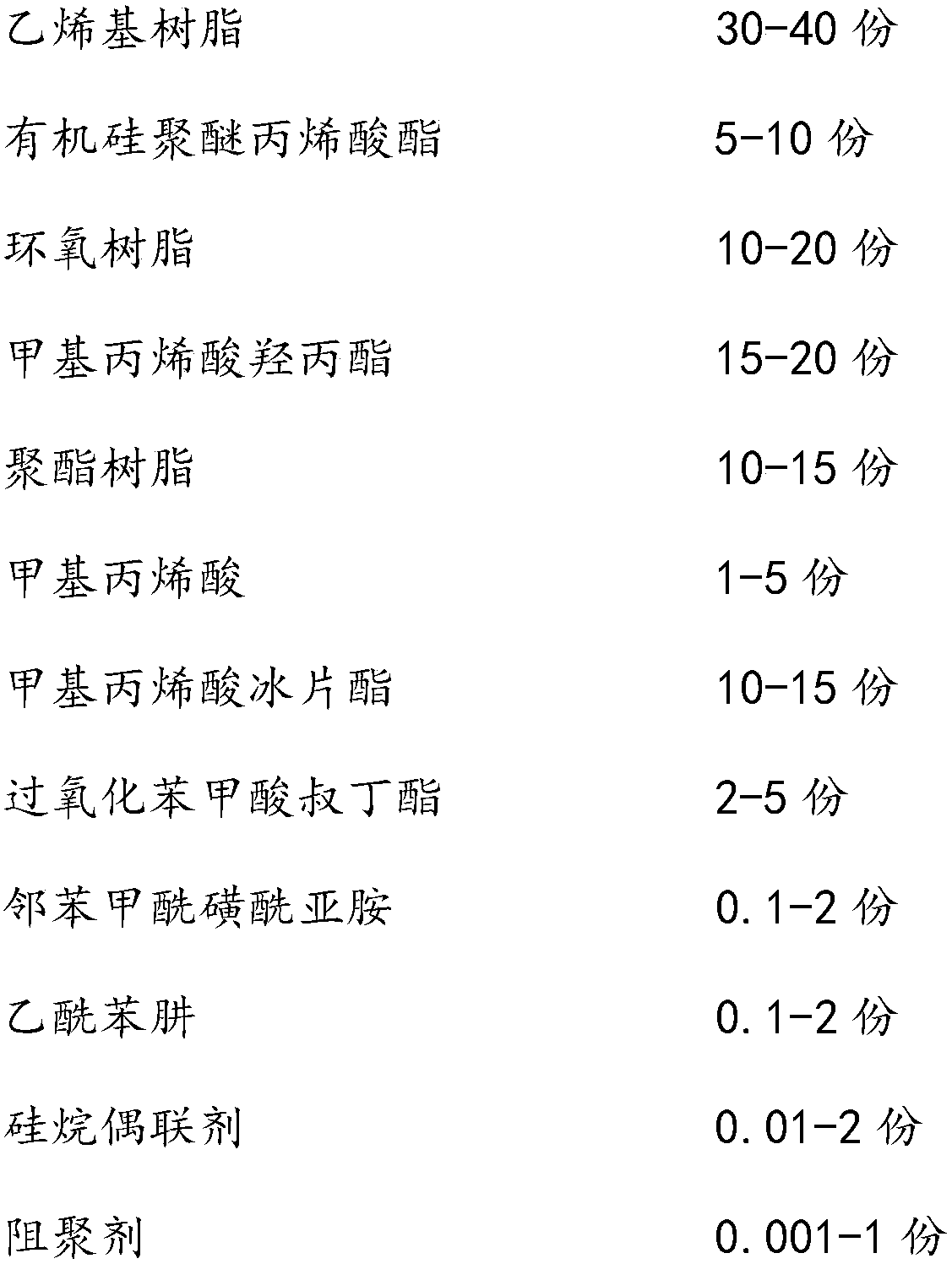

[0032] An anaerobic adhesive for cutting photovoltaic resin panels, including anaerobic adhesive and a surface accelerator, wherein the anaerobic adhesive includes vinyl resin, silicone polyether acrylate, epoxy resin, hydroxypropyl methacrylate, polyester Ester resin, methacrylic acid, bornyl methacrylate, tert-butyl peroxybenzoate, o-benzoylsulfonimide, acetylphenylhydrazine, silane coupling agent and polymerization inhibitor.

[0033] Surface accelerators include copper acetate and ethanol.

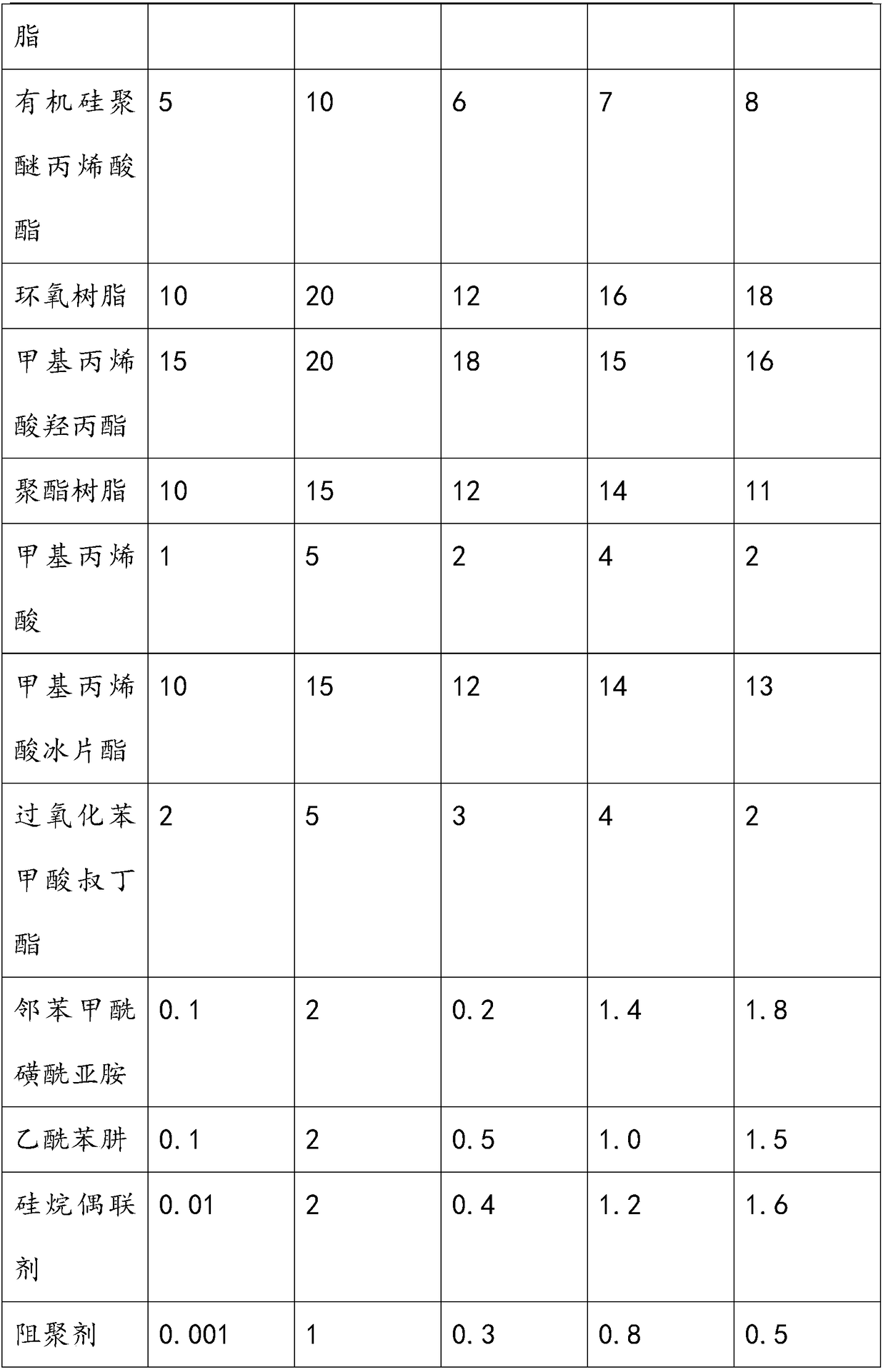

[0034] Each material composition is the same among embodiment 1-embodiment 5, but material content is different, see shown in table 1 below for details, and following material components are by weight.

[0035] Table 1:

[0036]

[0037]

[0038]

Embodiment 6

[0040] A preparation method of anaerobic adhesive for photovoltaic resin board cutting, comprising the following steps:

[0041] Step 1: Preparation of anaerobic glue;

[0042] Step 1.1: Mix 30-40 parts of vinyl resin, 5-10 parts of silicone polyether acrylate, 10-20 parts of epoxy resin, 15-20 parts of hydroxyethyl methacrylate, 10-15 parts of polyester resin, 1-5 parts of methacrylic acid and 10-15 parts of bornyl methacrylate are mixed to form mixture A;

[0043] Step 1.2: Heat the mixture A prepared in step 1.1 to 50-100°C, and gradually add 0.001-1 part of polymerization inhibitor to it during the heating process, and stir at high speed for 2-4 hours;

[0044] Step 1.3: Add 2-5 parts of tert-butyl peroxybenzoate, 0.1-2 parts of o-benzoylsulfonimide, 0.1-2 parts of acetylphenylhydrazine, and 0.01-2 parts of silane to the mixture prepared in step 1.2 The coupling agent forms mixture B;

[0045] Step 1.4: Stir the mixture B prepared in step 1.3 evenly and then evacuate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com