Bio-based carbon microsphere material, preparation method and applications thereof

A bio-based carbon and microsphere technology, applied in the preparation/purification of carbon, electrochemical generators, electrical components, etc., can solve the problems of limited fuel cells, high cost, low theoretical capacity, etc., and achieve a simple preparation process and reduce The effect of environmental pollution and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Preparation of bio-based carbon microspheres: Weigh 1.9 g chitosan, 0.1 g gallic acid and 30 mL distilled water into a 50 mL reactor with a polytetrafluoroethylene liner, react at 170 °C for 12 h, and react After cooling to room temperature, the obtained black product was centrifuged, and the collected black solid was repeatedly washed with ethanol and deionized water, and then dried in a vacuum oven at 90°C to obtain catalytically active nitrogen doped carbon microspheres.

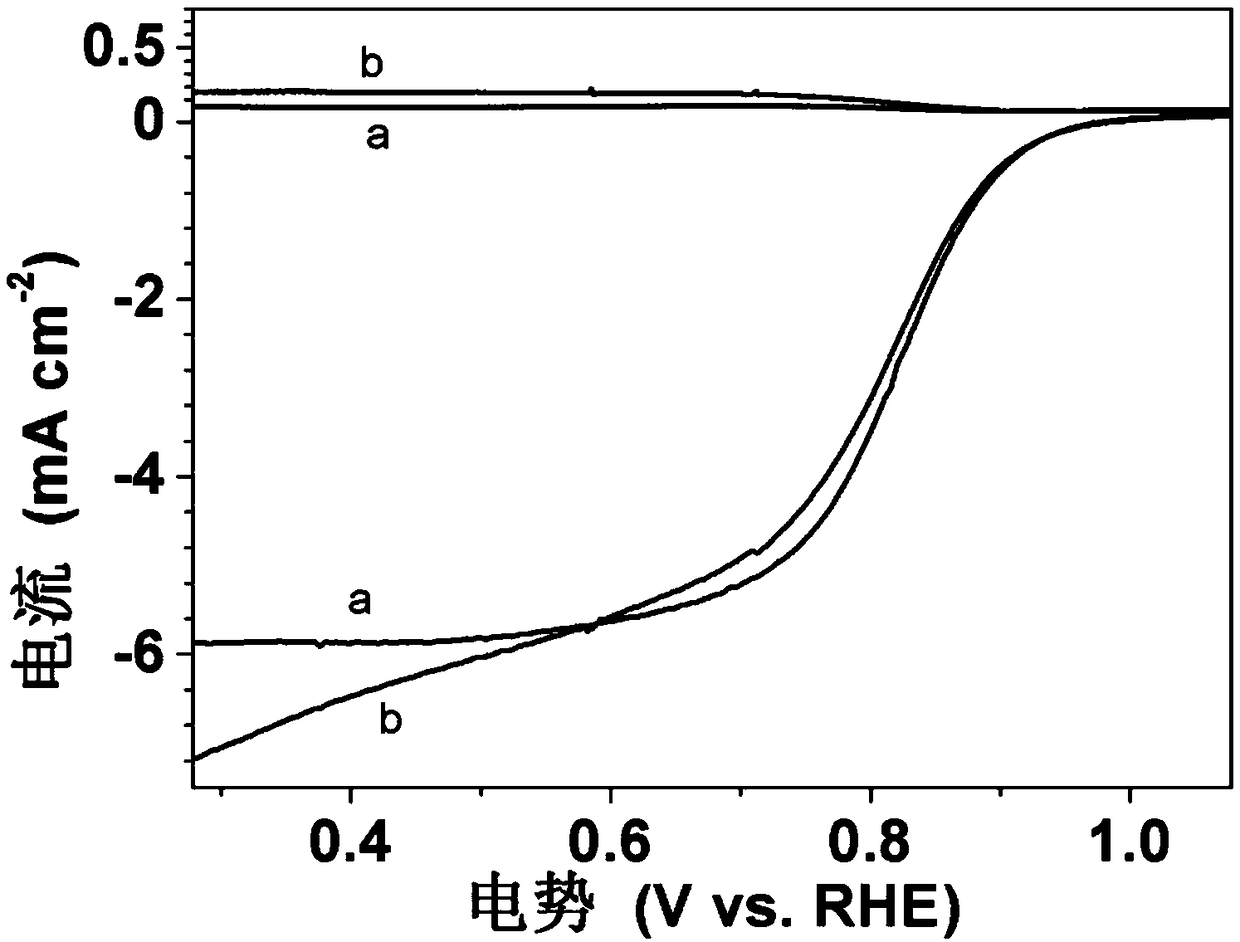

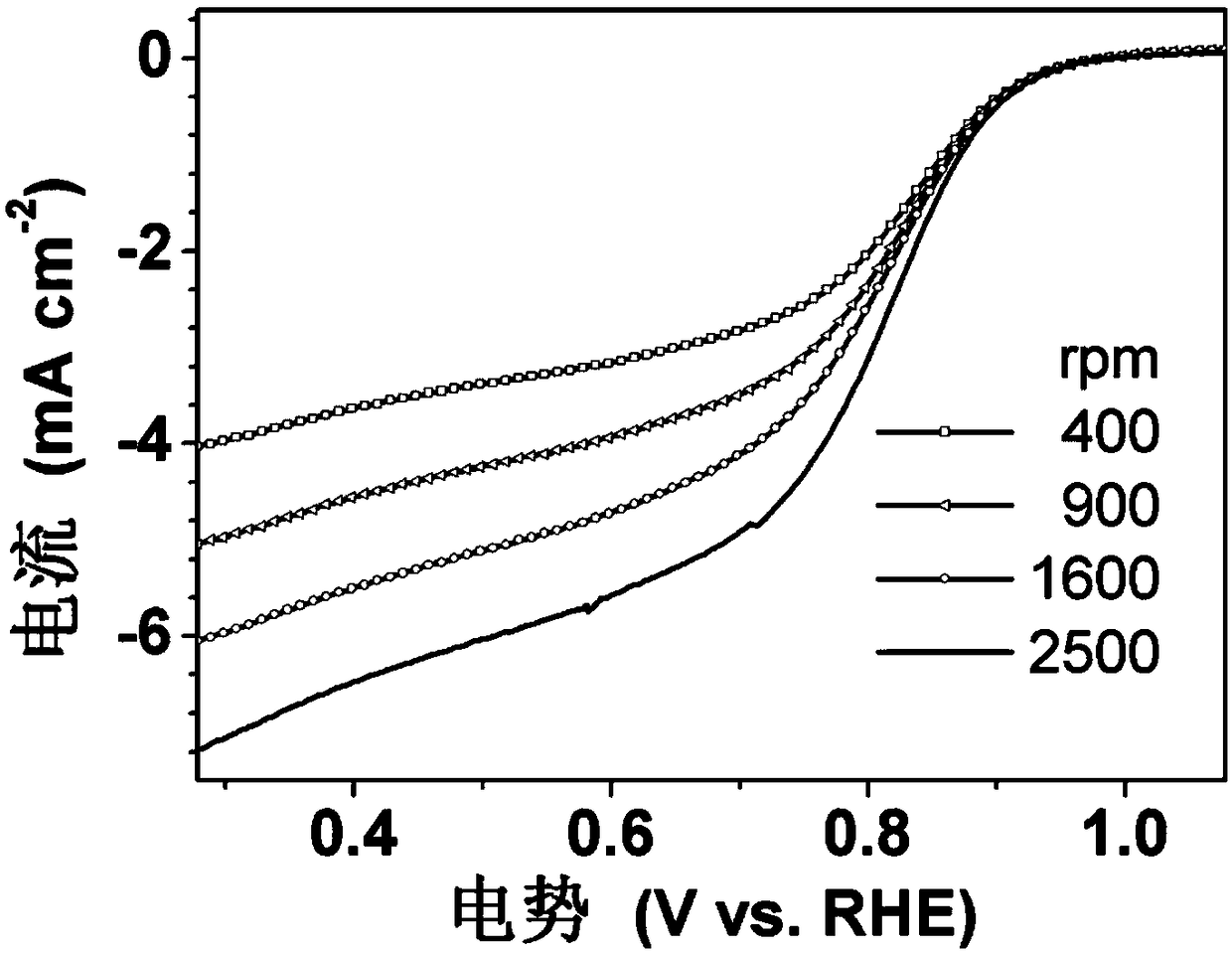

[0015] Test the application of N-doped carbon microspheres as a catalyst in ORR: the prepared nitrogen-doped carbon microspheres were uniformly dispersed in a mixed solution of deionized water and Nafion (Dupont, 5 wt.%) alcohol solution, and the The above suspension was coated on the surface of the glassy carbon electrode to prepare a working electrode. At the same time, for comparison, the commercial Pt / C (20% Pt, JM) catalyst prepared by the same method was tested under the same conditions.

...

Embodiment 2

[0019] Preparation of bio-based carbon microspheres: Weigh 1.8 g chitosan, 0.2 g gallic acid and 30 mL distilled water into a 50 mL reactor with a polytetrafluoroethylene liner, react at 180 °C for 24 h, and react After cooling to room temperature, the obtained black product was centrifuged, and the collected black solid was repeatedly washed with ethanol and deionized water, and then dried in a vacuum oven at 90°C to obtain catalytically active nitrogen doped carbon microspheres.

[0020] Test the application of N-doped carbon microspheres as a catalyst in ORR: the prepared nitrogen-doped carbon microspheres were uniformly dispersed in a mixed solution of deionized water and Nafion (Dupont, 5 wt.%) alcohol solution, and the The above suspension was coated on the surface of the glassy carbon electrode to prepare a working electrode. At the same time, for comparison, the commercial Pt / C (20% Pt, JM) catalyst prepared by the same method was tested under the same conditions.

...

Embodiment 3

[0024] Preparation of bio-based carbon microspheres: Weigh 1.6 g chitosan, 0.4 g gallic acid and 30 mL distilled water into a 50 mL reactor with polytetrafluoroethylene liner, react at 180 °C for 24 h, and react After cooling to room temperature, the obtained black product was centrifuged, and the collected black solid was repeatedly washed with ethanol and deionized water, and then dried in a vacuum oven at 90°C to obtain catalytically active nitrogen doped carbon microspheres.

[0025] Test the application of N-doped carbon microspheres as a catalyst in ORR: the prepared nitrogen-doped carbon microspheres were uniformly dispersed in a mixed solution of deionized water and Nafion (Dupont, 5 wt.%) alcohol solution, and the The above suspension was coated on the surface of the glassy carbon electrode to prepare a working electrode. At the same time, for comparison, the commercial Pt / C (20% Pt, JM) catalyst prepared by the same method was tested under the same conditions.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com