Biodegradable light conversion film and preparation method thereof

A technology of biodegradable and light-converting film, which is applied in botany equipment and methods, plant protection, plant protection covers, etc., can solve the problems of crop yield reduction, difficulty in recycling, soil structure damage, etc., to improve yield and quality, Significant economic and social significance, effect of reducing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

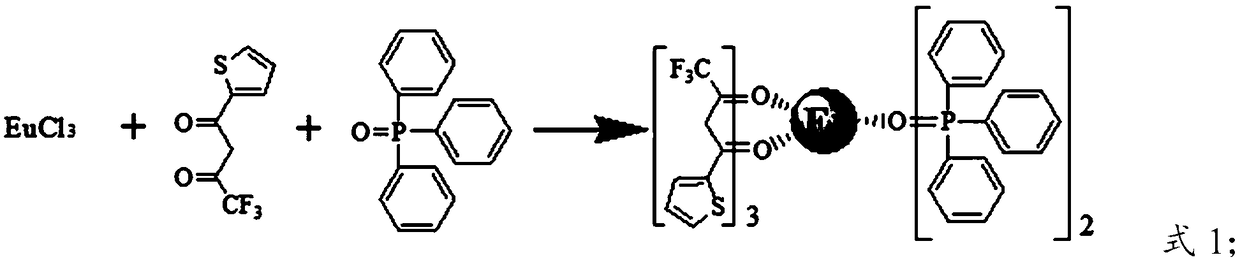

[0050] The present invention also provides a preparation method of a biodegradable light converting agent, comprising the following steps:

[0051] Mechanically blend 60-64.7 parts of polybutylene adipate-terephthalate, 35 parts of polylactic acid, 0.1-2 parts of lubricant, 0.1-2 parts of blocking agent and 0.1-1 part of light-changing agent in sequence , extrusion granulation and film blowing to obtain a biodegradable light conversion film.

[0052] In the present invention, the types, sources and amounts of each raw material are consistent with the types, sources and amounts of each raw material mentioned above, and will not be repeated here.

[0053] In the present invention, the mechanical blending is a commonly used mixing method in the field, and the present invention does not make special restrictions on this, as long as all materials can be mixed evenly, the time of the mechanical blending is preferably 3 to 10 minutes, more preferably Preferably it is 5 minutes.

[...

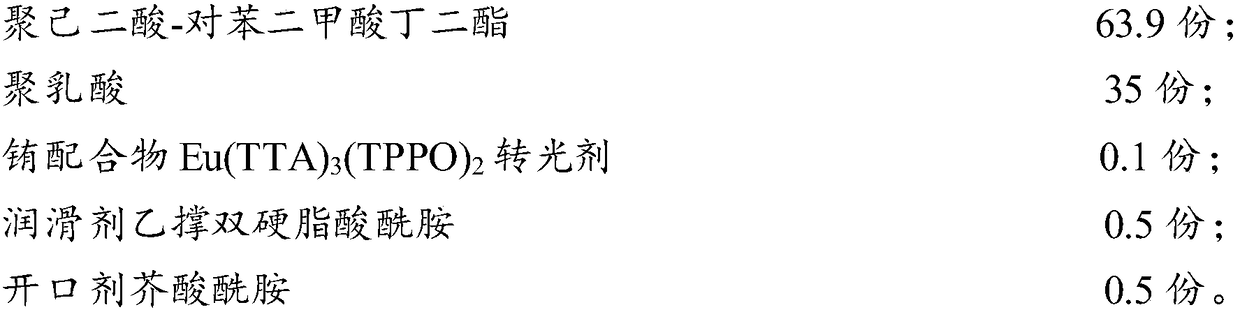

Embodiment 1

[0065]

[0066] According to the above ratio, the dry polybutylene adipate-terephthalate, polylactic acid, light-changing agent, lubricant, anti-blocking agent were mechanically blended for 5 minutes, and then the mixed materials were added to the twin-screw extruder. Melt extrusion and granulation in the extruder to obtain light-changing blown film resin; the set temperature of the twin-screw extruder is: zone 1: 165-175°C, zone 2: 165-180°C, zone 3: 165-190°C ℃, Zone 4: 165-190℃, Zone 5: 165-190℃, Zone 6: 165-190℃, Zone 7: 165-190℃, Zone 8: 165-190℃, Head: 165-190℃, Screw speed: 100-300rpm. The set temperature of the film blowing machine is: Zone 1: 155-160°C, Zone 2: 165-175°C, Zone 3: 165-175°C, Zone 4: 165-175°C, Zone 5: 180-195°C, the host Screw speed: 50~300rpm, traction speed 2~6m / min, inflation ratio 2~6. The thickness of the film was controlled at 0.04mm, and the mechanical properties and fluorescence spectrum of the film were tested. The test results are listed...

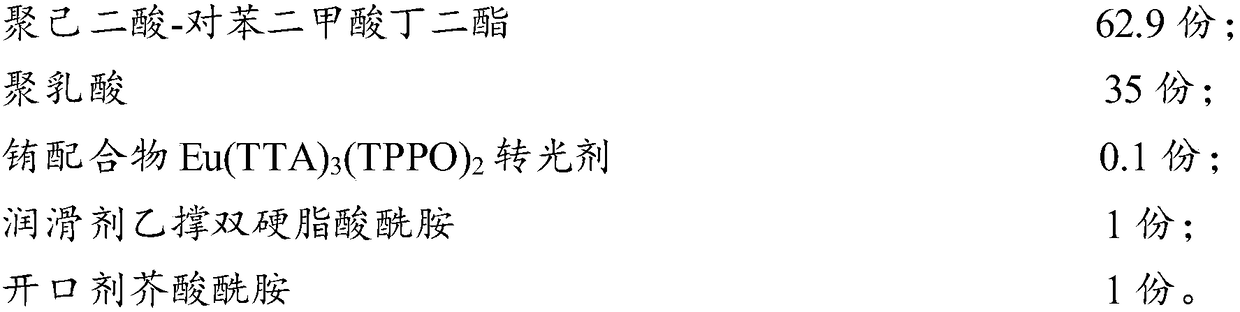

Embodiment 2

[0068]

[0069] In this example, the extrusion granulation and film blowing process are the same as in Example 1, the thickness of the film is controlled at 0.04mm, and the mechanical properties and light transmittance of the film are tested. The test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com