Aqueous road marking paint and preparation method thereof

A technology for marking paint and roads, applied in the field of coatings, can solve problems such as poor gloss, volatilization and toxicity, and human injury, and achieve the effects of safe operation, excellent wear resistance and water resistance, and extensive adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

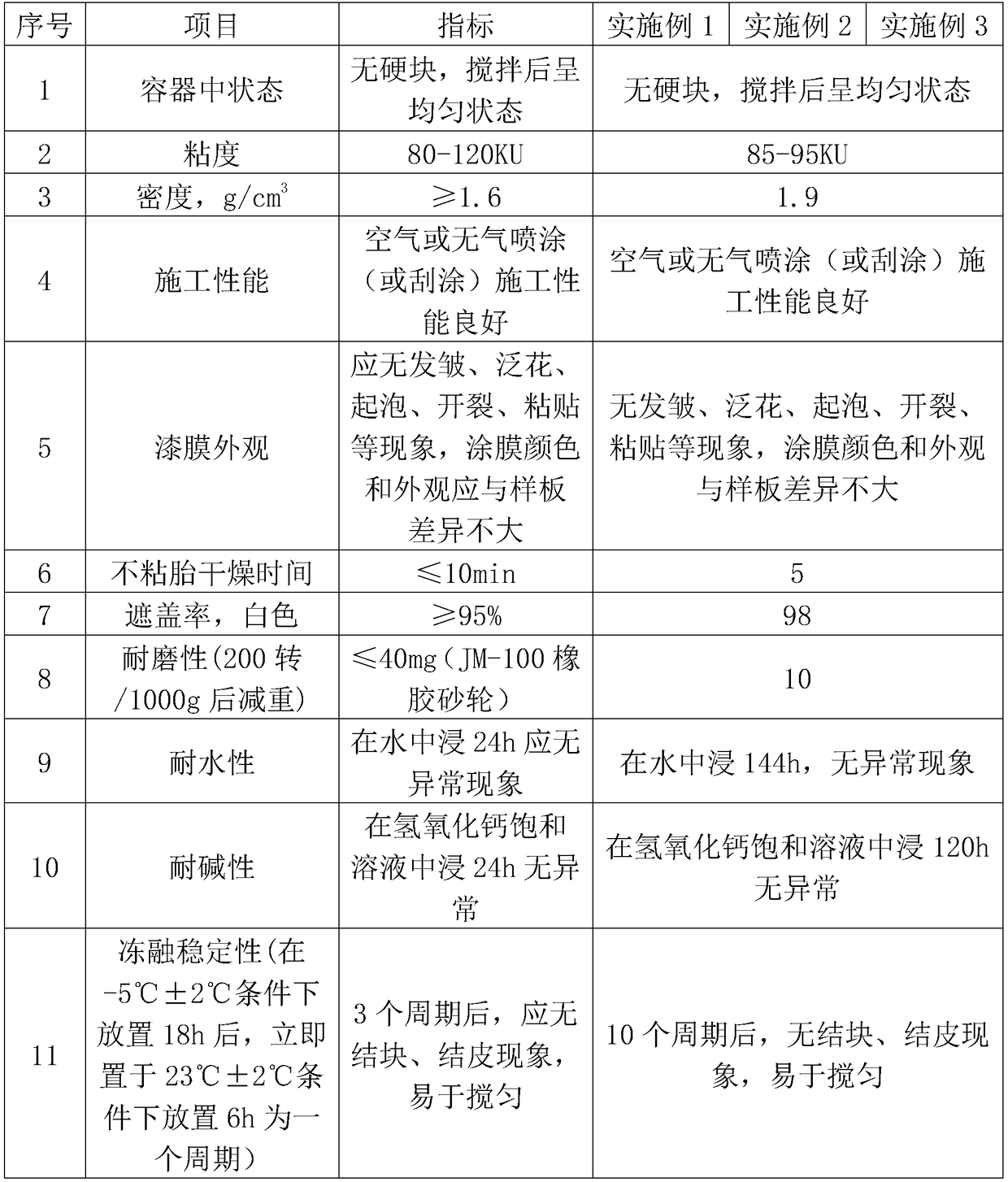

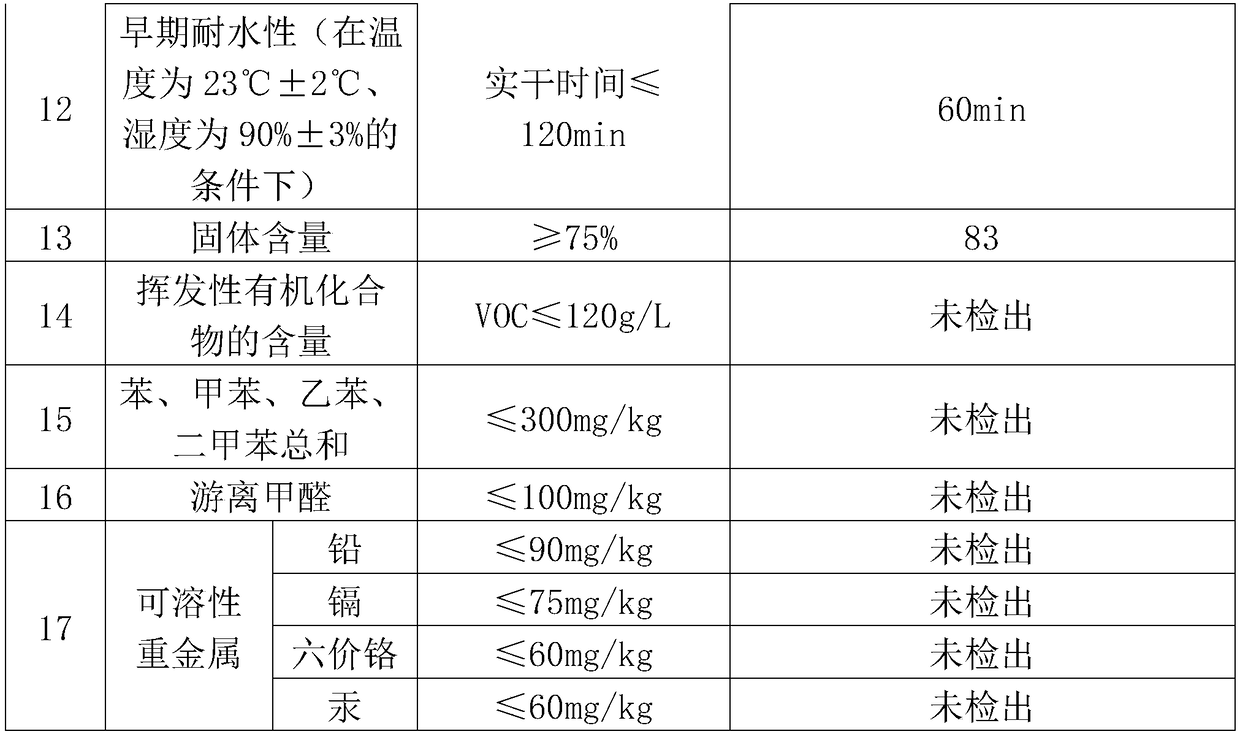

Examples

Embodiment 1

[0026] The preparation of embodiment 1 water-based road marking paint

[0027] (1) Raw material ratio

[0028] The raw material ratio of preparing water-based road marking paint is: by weight percentage, polyester composite acrylic acid emulsion 20%, glass beads 26%, titanium dioxide 16%, talcum powder 15%, anti-settling agent 1%, antifreezing agent 0.5% , dispersant 0.5%, wetting agent 0.1%, defoamer 0.3%, pH regulator 0.2%, preservative 0.2%, thickener 0.2%, water 20%.

[0029] Among them, titanium dioxide is rutile titanium dioxide, the content of titanium dioxide is greater than 95%, and the whiteness is greater than 94%; talc is white silicate mineral, the particle size is 800-1250 mesh, and the whiteness is greater than 90%. Polyamide anti-sedimentation agent; antifreeze agent is propylene glycol; dispersant is polyacrylic acid sodium salt dispersant, solid content 40%; wetting agent is fatty alcohol alkoxylate; 5400; the pH regulator is 2-amino-2-methyl-1-propanol; th...

Embodiment 2

[0034] The preparation of embodiment 2 water-based road marking paint

[0035] (1) Raw material ratio

[0036] The raw material ratio of preparing water-based road marking paint is: by weight percentage, polyester composite acrylic acid emulsion 18%, glass beads 27%, titanium dioxide 17%, talcum powder 13%, anti-settling agent 1.5%, antifreezing agent 0.6% , dispersant 0.6%, wetting agent 0.1%, defoamer 0.4%, pH regulator 0.2%, preservative 0.3%, thickener 0.3%, water 21%.

[0037] Among them, titanium dioxide is rutile titanium dioxide, the content of titanium dioxide is greater than 95%, and the whiteness is greater than 94%; talc is white silicate mineral, the particle size is 800-1250 mesh, and the whiteness is greater than 90%. Polyamide anti-sedimentation agent; antifreeze agent is propylene glycol; dispersant is polyacrylic acid sodium salt dispersant, solid content 40%; wetting agent is fatty alcohol alkoxylate; 5400; the pH regulator is 2-amino-2-methyl-1-propanol; ...

Embodiment 3

[0042] The preparation of embodiment 3 water-based road marking paint

[0043] (1) Raw material ratio

[0044] The raw material ratio of preparing water-based road marking paint is: by weight percentage, polyester composite acrylic acid emulsion 15%, glass beads 28%, titanium dioxide 18%, talcum powder 12%, anti-settling agent 1.4%, antifreeze agent 1% , dispersant 0.8%, wetting agent 0.2%, defoamer 0.5%, pH regulator 0.3%, preservative 0.4%, thickener 0.4%, water 22%.

[0045] Among them, titanium dioxide is rutile titanium dioxide, the content of titanium dioxide is greater than 95%, and the whiteness is greater than 94%; talc is white silicate mineral, the particle size is 800-1250 mesh, and the whiteness is greater than 90%. Polyamide anti-sedimentation agent; antifreeze agent is propylene glycol; dispersant is polyacrylic acid sodium salt dispersant, solid content 40%; wetting agent is fatty alcohol alkoxylate; 5400; the pH regulator is 2-amino-2-methyl-1-propanol; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap